Intergranular corrosion resistant austenitic system stainless steel

A technology of austenitic stainless steel and austenitic system, applied in the field of austenitic stainless steel, can solve problems such as corrosion, stainless steel hot crack intergranular, etc., achieve the effect of preventing hot crack and improving intergranular corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

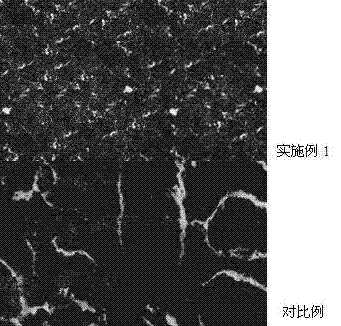

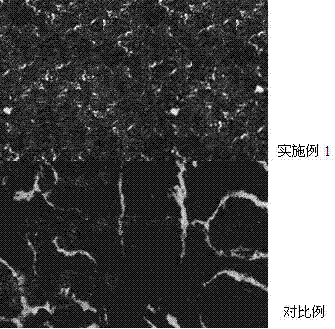

Image

Examples

Embodiment

[0022] As shown in Table 1, the components of the austenitic stainless steels in Examples 1, 2, 3, and 4 and their mass percentage (wt%) balance are Fe, and the austenitic stainless steels in Examples 1, 2, 3, and 4 are preferably Welding is performed with a linear energy of 1kJ / cm, and the cooling rate is 30°C / s, and the interlayer temperature of the multilayer welding is 70°C.

[0023] Table 1 Austenitic stainless steel components and their mass percentages (wt%) in Examples 1, 2, 3, and 4

[0024] C Si mn P S Cr Ni Ti Example 1 0.08 0.73 1.95 0.03 0.016 24.6 11.4 0.75 Example 2 0.065 0.42 2.07 0.03 0.010 26.2 12.3 0.80 Example 3 0.02 0.35 1.55 0.02 0.015 26.4 11.2 0.65 Example 4 0.09 0.9 2.4 0.02 0.018 24.2 13 1.0

[0025] Ti is added to the intergranular corrosion-resistant austenitic stainless steel of Examples 1, 2, 3, and 4, so that the mass percentage of Ti is preferably 0.75%, 0.80%, 0.65%,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com