Sprocket tooth part induction heat treatment process

A technology of induction heat treatment and sprocket teeth, applied in heat treatment furnace, heat treatment equipment, improvement of process efficiency, etc., can solve the problems of high cooling speed of quenching medium, uneven surface hardness, cracks in sprocket teeth, etc. The effect of uniform grain refinement, improved process level, and prevention of cracks or fractures in the sprocket teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] An example of the present invention is as follows:

[0027] An induction heat treatment process for sprocket teeth, comprising the following steps:

[0028] 1. After installing the induction coil first, install the sprocket workpiece on the workpiece position in the induction coil, adjust the height of the induction coil and the sprocket tooth part, so that the center of the induction coil and the quenched part of the sprocket tooth part corresponds to the gap Uniform;

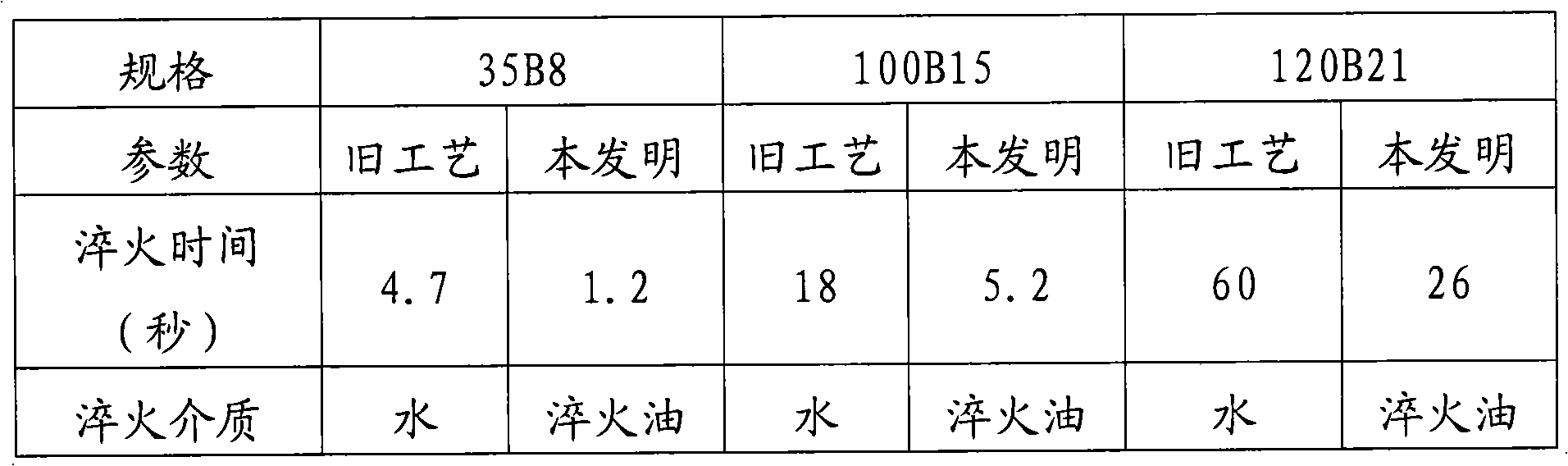

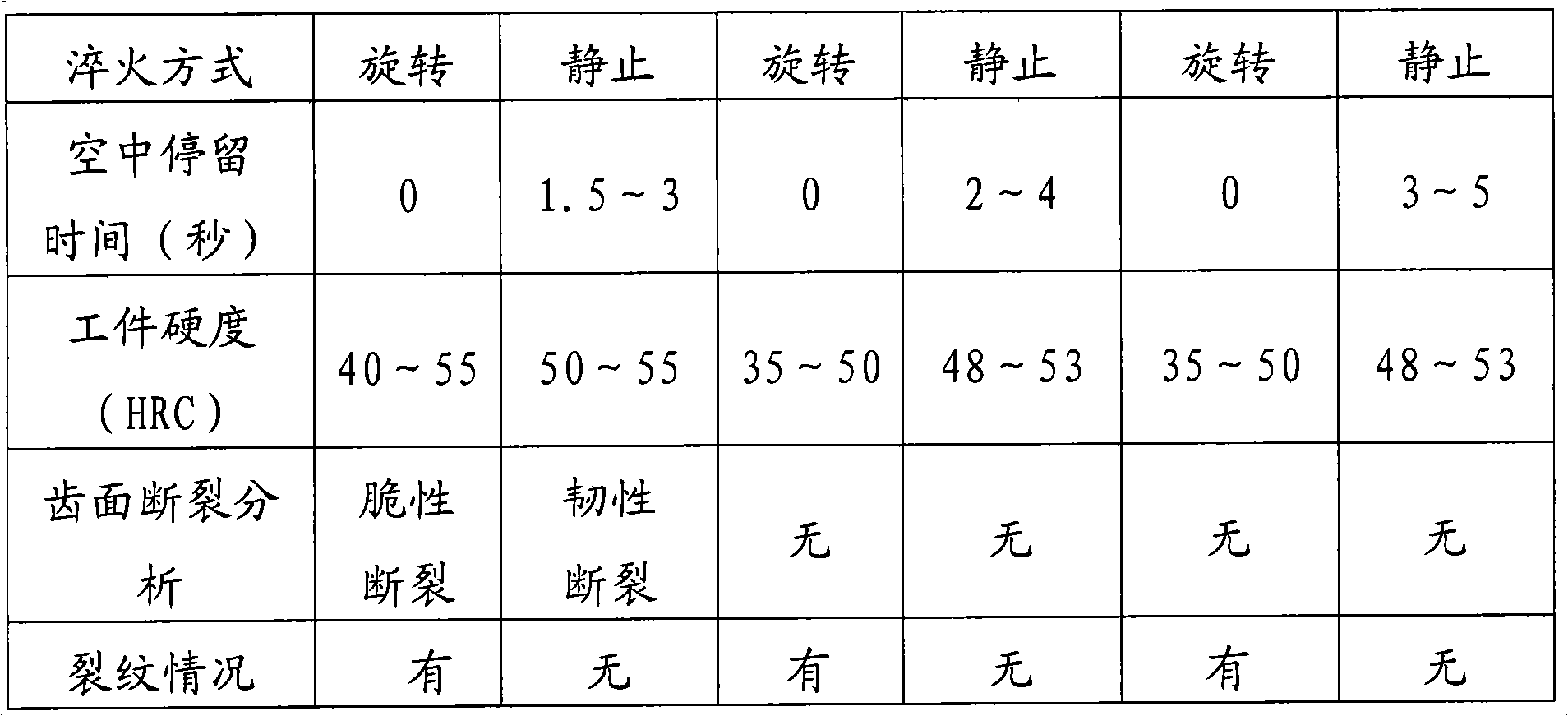

[0029] 2. Supply water and electricity to the induction coil. The minimum input single-phase current of the induction coil is 120A, and the maximum shall not exceed 250A. At the same time, the sprocket workpiece is rotated for heat treatment. The rotation speed of the sprocket workpiece is: when the diameter of the workpiece is below 200mm , it is required to be 250-600n / min; when the diameter of the workpiece is greater than 200mm, it is required to be 150-450n / min, and the minimum quenching time is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com