Zn-Mg alloy ingot and preparation method thereof

A technology of alloy ingot casting and magnesium-zirconium master alloy, which is applied in the field of alloys, can solve problems such as poor plasticity and serious thermal cracking tendency, and achieve the effects of improved casting performance, comprehensive performance enhancement, and uniform grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the above-mentioned zinc-magnesium alloy includes a melting process and a heat treatment process, and the specific steps are as follows:

[0028] The smelting process is in N 2 and SF 6 Under the condition of mixed gas protection, the steps are as follows:

[0029] (1) Weighing and baking materials: according to the mass percentage of raw materials, weigh pure magnesium ingots, pure zinc ingots, magnesium-zirconium master alloys, magnesium-calcium master alloys, magnesium-cerium master alloys and magnesium-yttrium master alloys respectively, and mix the various raw materials Preheat in a preheating furnace at 280°C for 10 hours;

[0030] (2) Melting: Put the preheated magnesium ingot in a melting furnace and heat it to 690°C until the pure magnesium ingot is completely melted, then raise the temperature to 740°C, add pure zinc ingot into the molten magnesium liquid, and wait until the pure zinc ingot is completely melted After melting, add t...

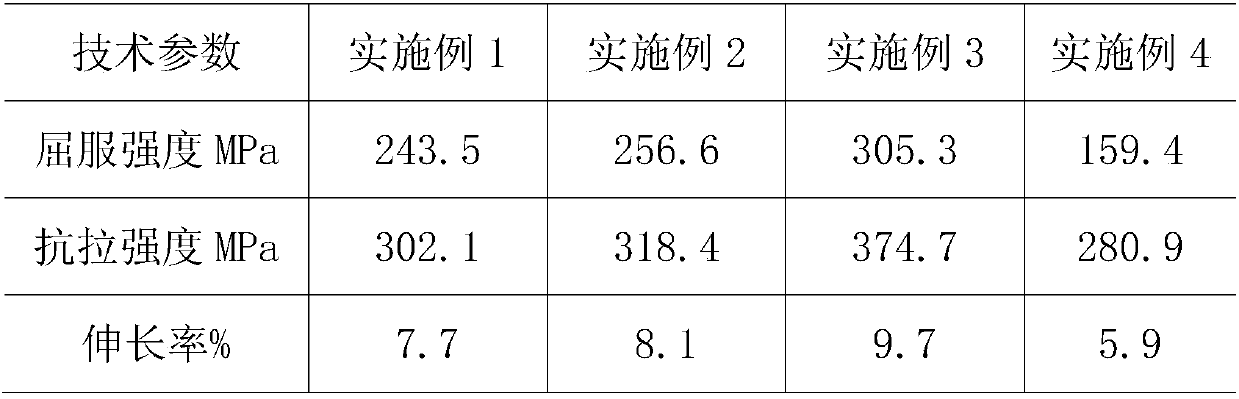

Embodiment 1

[0035] The preparation method of embodiment 1-3 is that above-mentioned preparation method comprises smelting process and heat treatment process, but embodiment 1 only adds magnesia cerium master alloy, embodiment 2 only adds magnesia yttrium master alloy, embodiment 3 adds magnesia cerium master alloy and Magnesium-yttrium master alloy; the preparation method of embodiment 4 is that the above-mentioned preparation method only includes the smelting process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com