Method for refining surface grains of 2Cr10NiMoVNb stainless steel forgings through quenching three times

A technology for stainless steel and forgings, which is applied in the field of three-time quenching to refine the surface grains of 2Cr10NiMoVNb stainless steel forgings. effect of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

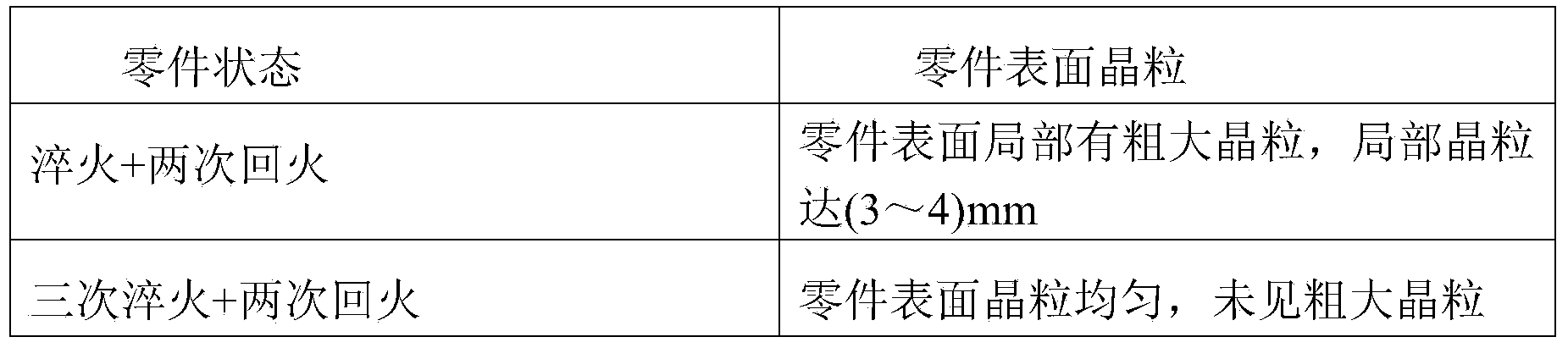

[0020] This embodiment is a method for refining the surface layer grains of 2Cr10NiMoVNb stainless steel forgings. The forging is a pie-shaped workpiece. Before the round cake-shaped workpiece has three times of quenching and grain refinement heat treatment, the normal heat treatment system is quenching + tempering, and coarse grains often appear on the surface of the part, and the local grains reach (3-4) mm.

[0021] The concrete process of this embodiment is:

[0022] Step 1: First quenching: first heat the air furnace to 950°C, put the forging in the air furnace, and raise the temperature to 950°C, and then keep it warm; Obtain the forging after the first quenching; wherein the holding time of this step is obtained by adding the basic holding time and the holding time determined according to the maximum thickness of the forging; the basic holding time is 30min, and the holding time determined according to the maximum thickness of the forging is: The holding time correspo...

Embodiment 2

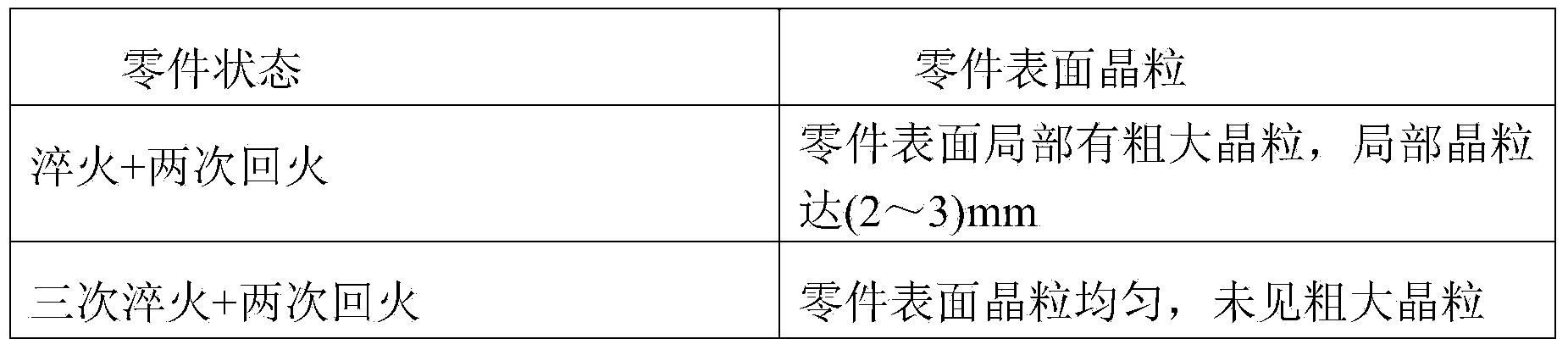

[0032] This embodiment is a method for refining the surface layer grains of 2Cr10NiMoVNb stainless steel forgings. The forging is an annular workpiece. The normal heat treatment system of the ring-shaped workpiece is quenching + tempering before three times of heat treatment for quenching and grain refinement. Coarse grains often appear on the surface of the part, and the local grains reach (2-3) mm.

[0033] The concrete process of this embodiment is:

[0034] Step 1: First quenching: firstly heat the air furnace to 1000°C, put the forging into the air furnace, and raise the temperature to 1000°C, and then keep it warm; Obtain the forging after the first quenching; wherein the holding time of this step is obtained by adding the basic holding time and the holding time determined according to the maximum thickness of the forging; the basic holding time is 30min, and the holding time determined according to the maximum thickness of the forging is: The holding time correspondin...

Embodiment 3

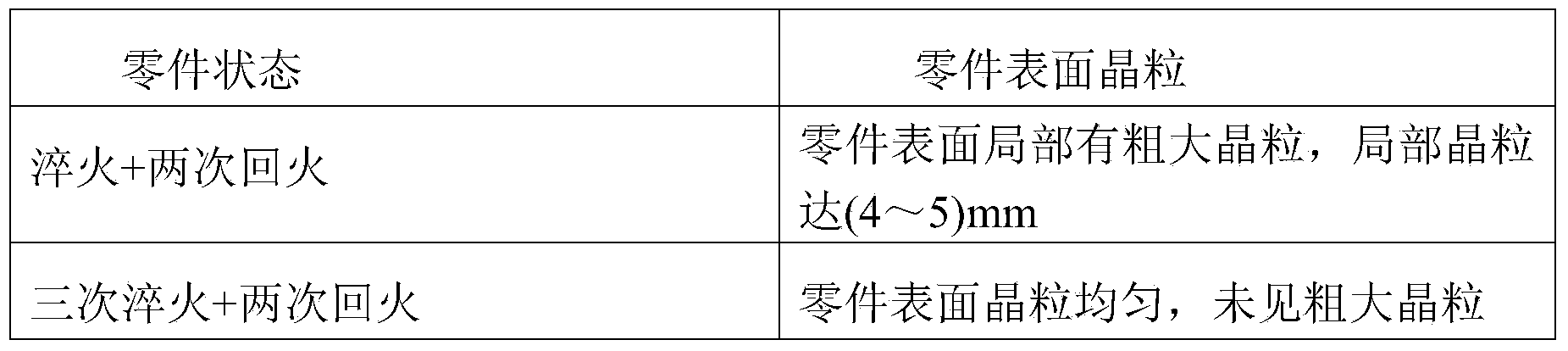

[0044] This embodiment is a method for refining the surface layer grains of 2Cr10NiMoVNb stainless steel forgings. The forging is a cuboid workpiece. The normal heat treatment system of the cuboid workpiece is quenching + tempering before three quenching and grain refinement heat treatments. Coarse grains often appear on the surface of the part, and the local grains reach (4-5) mm.

[0045] The concrete process of this embodiment is:

[0046] Step 1: First quenching: first heat the air furnace to 1050°C, put the forging in the air furnace, and raise the temperature to 1050°C, and then keep it warm; Obtain the forging after the first quenching; wherein the holding time of this step is obtained by adding the basic holding time and the holding time determined according to the maximum thickness of the forging; the basic holding time is 30min, and the holding time determined according to the maximum thickness of the forging is: The holding time corresponding to each mm thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com