Heat treatment process after forging of ultra-heavy tube plate forgings splicing-welded in pressure container

A post-forging heat treatment and pressure vessel technology, which is applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of not being able to improve the mechanical properties of materials, stress concentration, and coarse grains of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention are given to illustrate the present invention, but do not constitute any limitation to the present invention. The ultra-large tube sheet forging of the present invention refers to a tube sheet with a diameter greater than 6 meters, and the super-large tube sheet of the pressure vessel is made of 20MnMoNb steel;

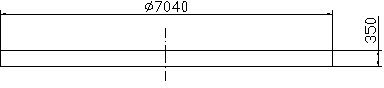

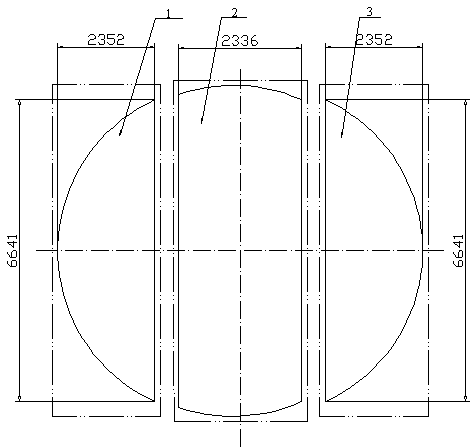

[0033] (1) Tube sheet segmentation

[0034] For super-large tube sheet forgings with a diameter of more than 6 meters, in order to improve the manufacturing quality stability of super-large tube sheets, the super-large tube sheets are divided into three pieces, namely arc-shaped block I1, rectangular block 2 and arc-shaped block II3, The arc-shaped block I1 and arc-shaped block II3 are concentric and have the same radius as the super-large tube sheet forging, the length of the rectangular block 2 is the same as the diameter of the super-large tube sheet forging, and the rectangular block 2 The two end faces in the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com