Super-thick steel plate for construction with excellent Z-directional performance and production method thereof

A technology for extra-thick steel plates and construction, applied in manufacturing tools, control of molten metal pouring from casting ladles, metal processing equipment, etc. Operation and other problems, to achieve the effect of convenient operation, excellent lamellar tear resistance and good welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

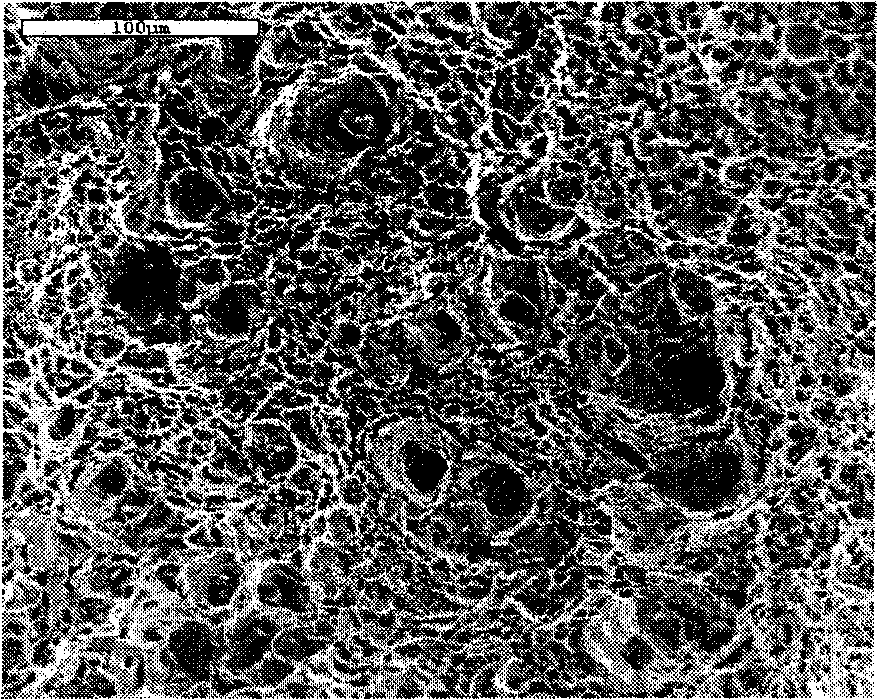

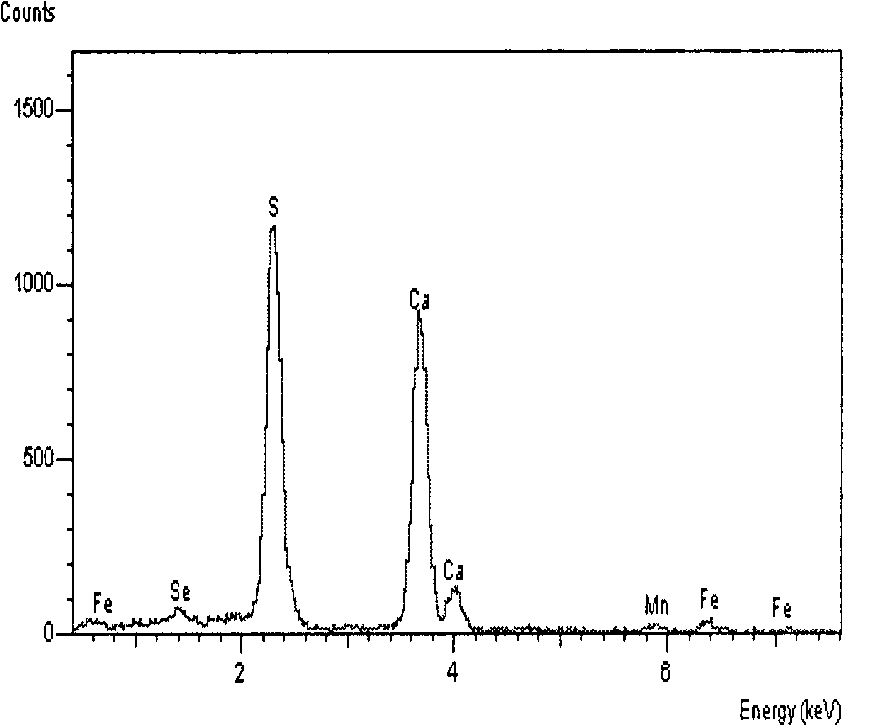

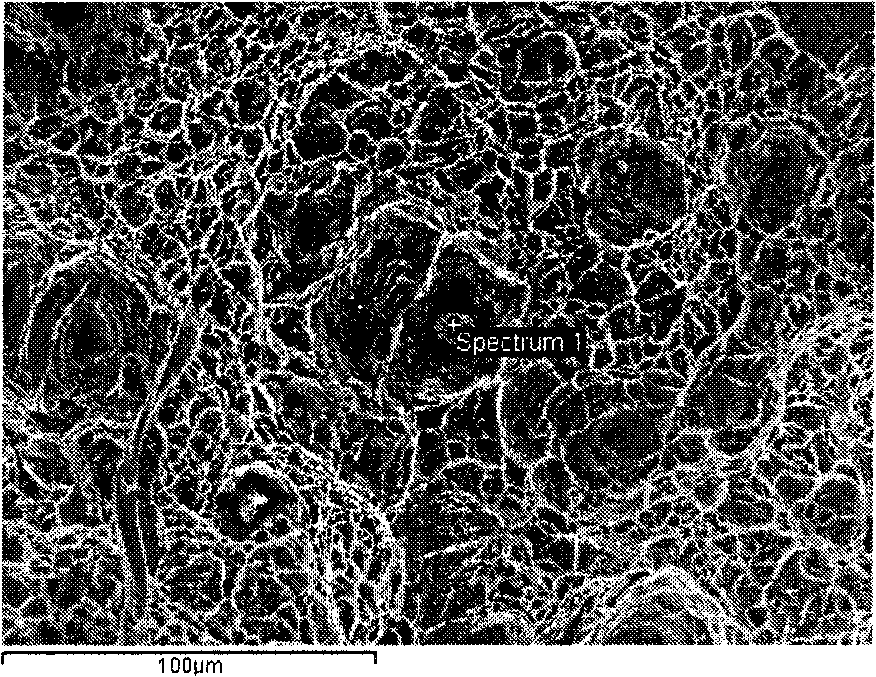

Image

Examples

Embodiment Construction

[0051] According to the steel chemical composition requirements of the present invention, that is, C: 0.10-0.22%, Si: 0.10-0.50%, Mn: 1.0-2.0%, P≤0.025%, S≤0.006%, Nb: 0.01-0.06%, V: 0.02 ~0.11%, Ti: 0.005~0.025%, Ca: 0.0004~0.0040%, Alt: 0.01~0.05%, H≤0.0002%, the balance is Fe and unavoidable inclusions, using pure steel smelting process, in the steelmaking plant A 300-ton converter was used for top-bottom combined blowing, and then for refining outside the furnace. The chemical compositions of Examples 1-8 are shown in Table 1, and the balance is Fe and unavoidable inclusions.

[0052] Heat the bloom to 1100-1250°C and perform free rolling (AR rolling) to ensure that the reduction ratio D / d is 3.0≤D / d≤7.0 (D: thickness of the bloom, d: thickness of the finished product), Air-cool to room temperature after rolling, and finally heat the steel plate to 860-920°C for normalizing heat treatment, and the holding time is 1.0-2.0min / mm. The final product thicknesses are: 60mm, 70m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com