Welded structure refractory and weathering steel with yield strength being no less than 620 MPa and production method thereof

A welding structure and yield strength technology, which is applied in the field of fire-resistant and weather-resistant steel for welded structures, can solve the problems of unsatisfactory welding performance, corrosion resistance, lack of fire resistance, unfavorable steel plate welding and low-temperature toughness, etc., and achieve good cold and hot processing The effect of performance, simple manufacturing process, and ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9

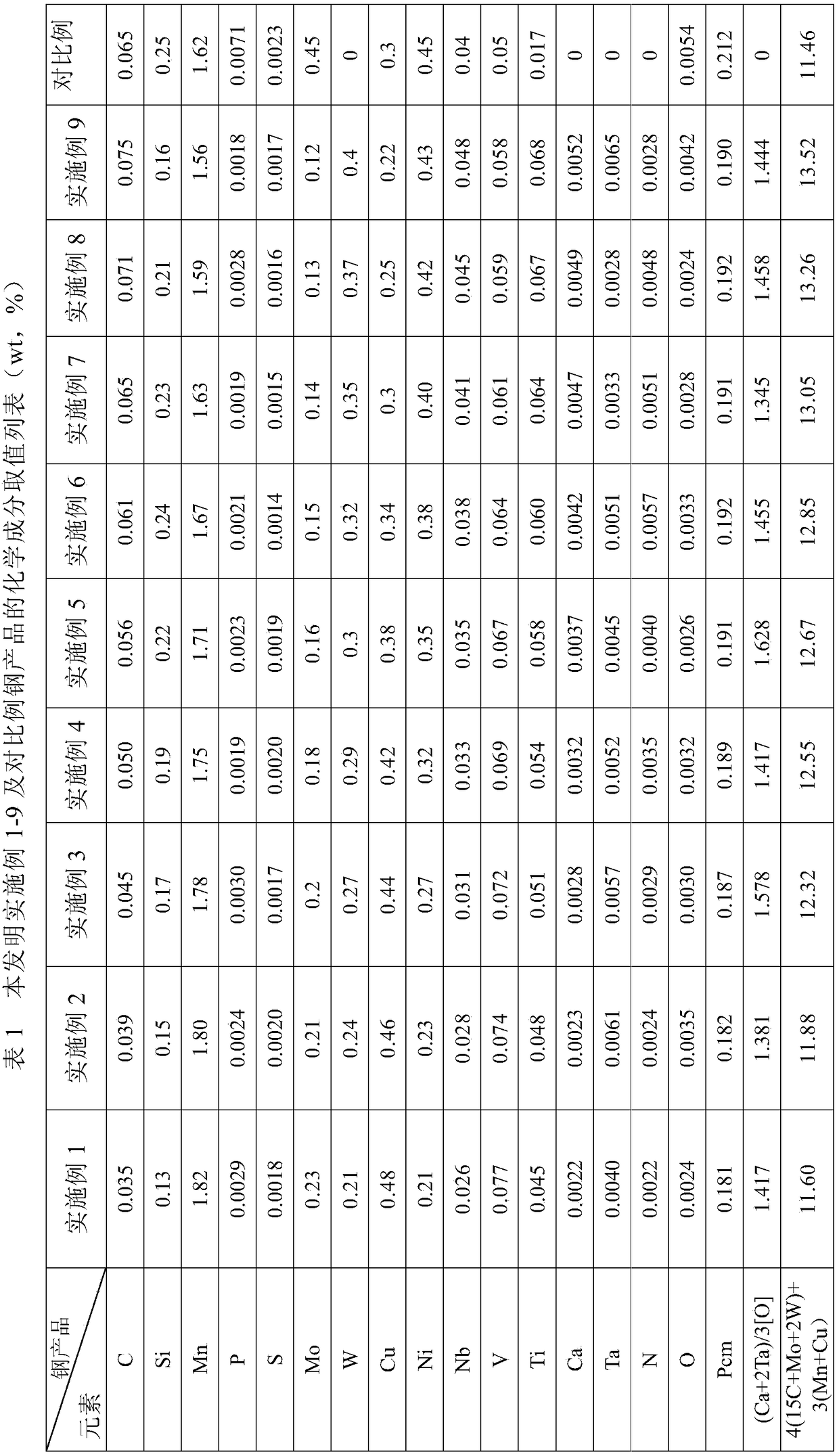

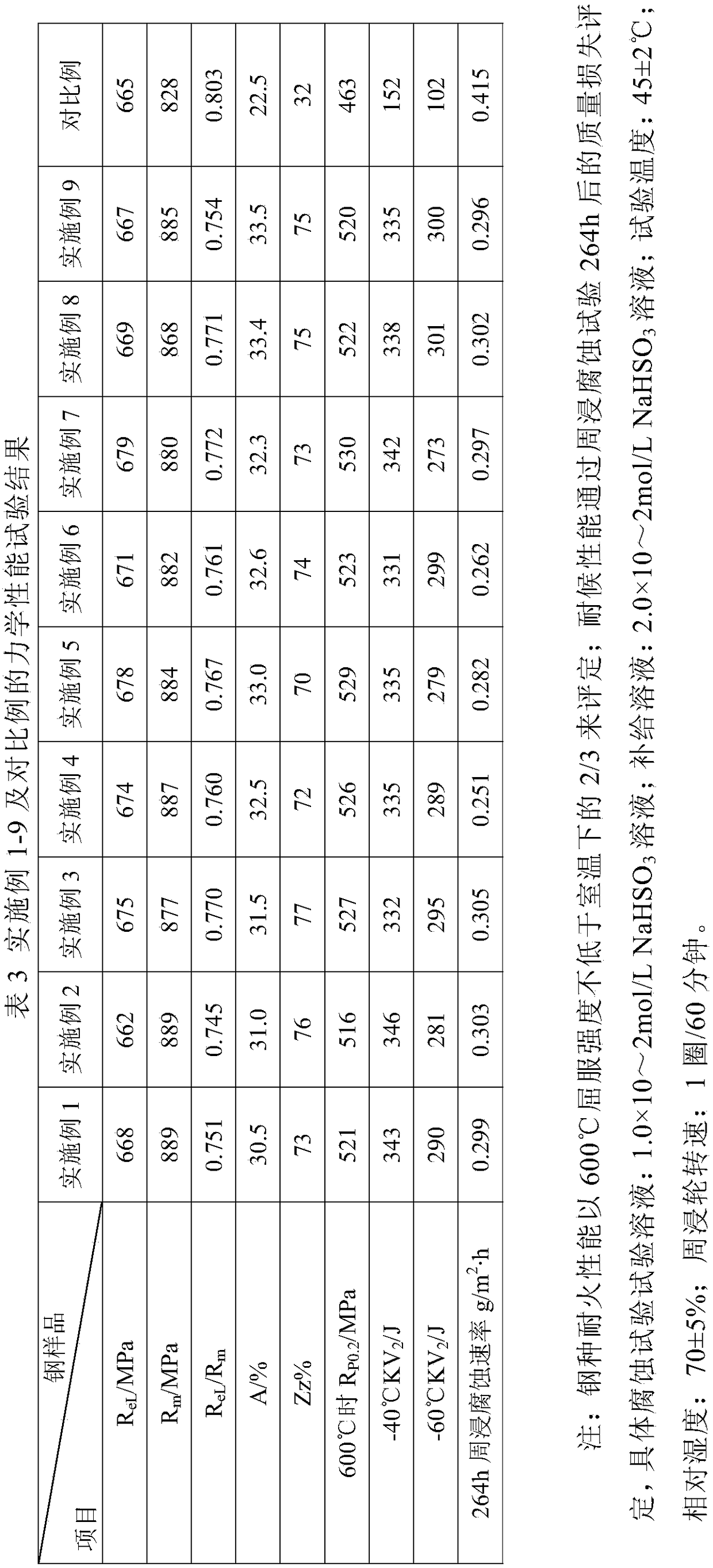

[0045]The embodiment of the present invention prepares a fire-resistant and weather-resistant steel for welded structures with a yield strength ≥ 620 MPa, its components and mass percentages are: C: 0.035-0.075%, Si: 0.13-0.24%, Mn: 1.56-1.82%, P≤0.003%, S≤0.002%, Mo: 0.12~0.23%, W: 0.21~0.40%, Cu: 0.22~0.48%, Ni: 0.21~0.43%, Nb: 0.026~0.048%, V: 0.058~0.077 %, Ti: 0.045~0.068%, Ca: 0.0022~0.0052%, Ta: 0.0028~0.0065%, [N]: 0.0022~0.0057%, [O]: 0.0024~0.0042%, the rest is Fe and unavoidable impurities, Satisfied at the same time: ①(Ca+2Ta) / 3[O]=1.32~1.65, ②4(15C+Mo+2W)+3(Mn+Cu)=11.52~13.61%, ③Pcm(%)=C+Si / 30 +(Mn+Cu) / 20+Ni / 60+Mo / 15+V / 10≤0.20%.

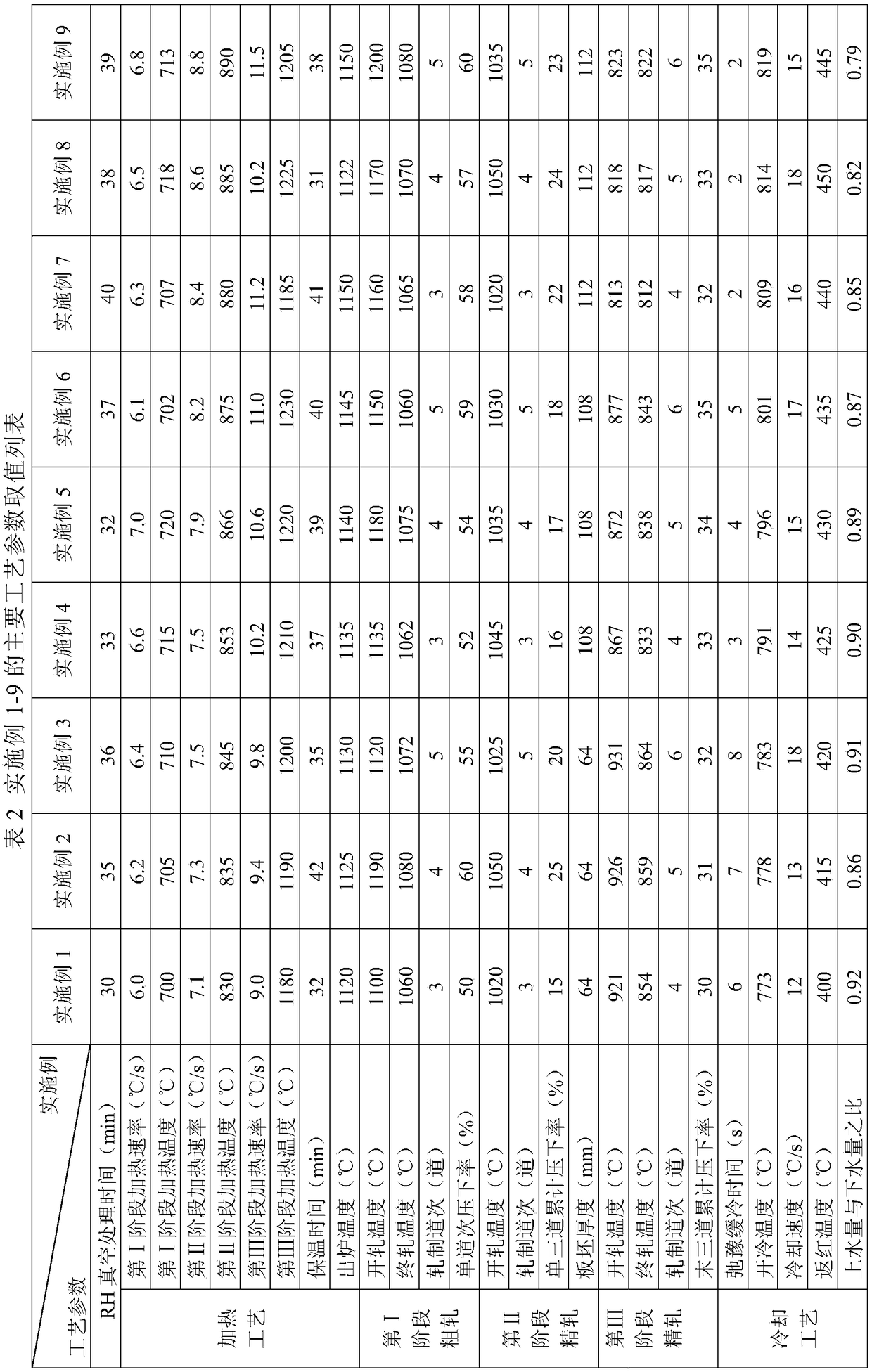

[0046] Its production method includes smelting and pouring into slabs, slab heating, high-pressure water dephosphorization, controlled rolling, laminar cooling and other process steps. The specific process steps are as follows:

[0047] 1) Smelting and pouring into slabs: Smelting and pouring molten iron to form slabs, controlling Ca: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com