Steel plate of thermal-pressure-resistant container used for furnace shell and manufacturing method of steel plate

A technology for a pressure vessel and a manufacturing method, which is applied in the field of heat-resistant pressure vessel steel plates for furnace shells and their manufacturing fields, can solve problems such as excess strength, and achieve the effects of stable performance, high safety factor, and strong mechanical impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

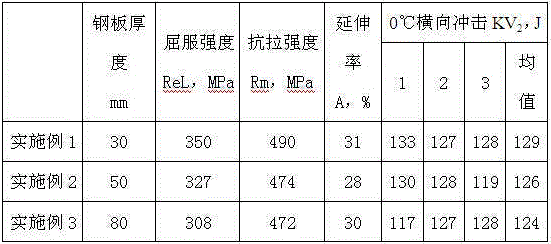

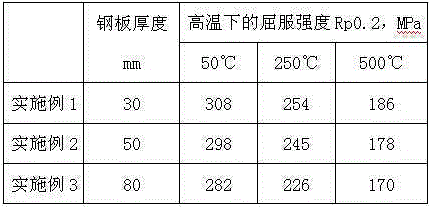

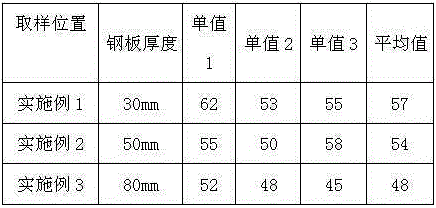

Embodiment 1

[0020] The heat-resistant pressure vessel steel plate for the furnace shell in this example is prepared from the following components in mass percentage: C: 0.18%, Si: 0.15%, Mn: 0.75%, P: 0.015%, S: 0.003%, Mo : 0.28%, Alt: 0.032%, the rest is Fe and unavoidable impurities.

[0021] The production preparation method of the heat-resistant pressure vessel steel plate for the furnace shell of the present embodiment is as follows:

[0022] 1) Smelting process: After the raw material molten iron is pretreated by KR, it is smelted in a 210t top-bottom combined blowing converter. After the converter is tapped, the ladle is blown with argon for 15 minutes and fed to the aluminum wire for deoxidation treatment. The molten steel is sent to the LF refining furnace for refining, and the temperature and composition are adjusted After the fine-tuning treatment, the vacuum treatment is carried out in the RH furnace. The vacuum time is 18 minutes. After the treatment, 2m / t of calcium iron wi...

Embodiment 2

[0028] The production and preparation method of the heat-resistant pressure vessel steel plate for the furnace shell in this embodiment, the thickness of the rolling intermediate billet is 110mm, the finishing rolling temperature is 820°C, water cooling to 630°C and then air cooling to room temperature, the finished rolled steel plate has a specification of 50mm, The normalizing temperature is 903°C and the furnace time is 75 minutes.

[0029] All the other features are the same as in Example 1.

Embodiment 3

[0031] The production and preparation method of the heat-resistant pressure vessel steel plate for the furnace shell in this embodiment, the steel is prepared from the following mass percentage components: C: 0.19%, Si: 0.27%, Mn: 0.82%, P: 0.014%, S: 0.002%, Mo: 0.30%, Alt: 0.030%, and the rest are Fe and unavoidable impurities.

[0032]After the converter is tapped, the ladle is blown with argon for 10 minutes, and the molten steel is vacuum treated by the RH furnace, and the vacuum is kept for 15 minutes. After the treatment, calcium iron wire is fed at 2.2m / t. After the wire is fed, the argon is blown softly for 20 minutes. About 120mm; the superheat of the tundish fluctuates in the range of 12-25°C, the heating time of the continuous casting billet in the heating furnace is 3 hours and 50 minutes, the thickness of the intermediate billet is 150mm, the finishing rolling temperature is 830°C, water cooling to 635°C and then air cooling to room temperature , The specificatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com