Engineering steel with excellent low-temperature impact toughness and lamellar tear resistance in core and production method thereof

A low-temperature impact toughness, anti-lamellar tearing technology, applied in the field of metallurgical steel, can solve the problems of deterioration of scale peeling, increase of production cycle and production cost, difficult to achieve, etc. The effect of external toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

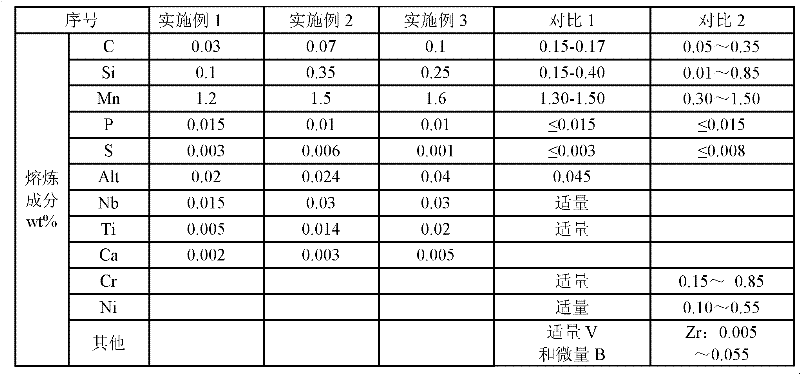

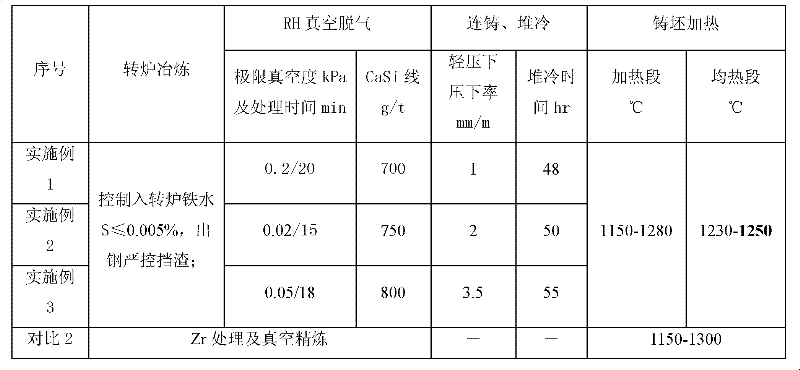

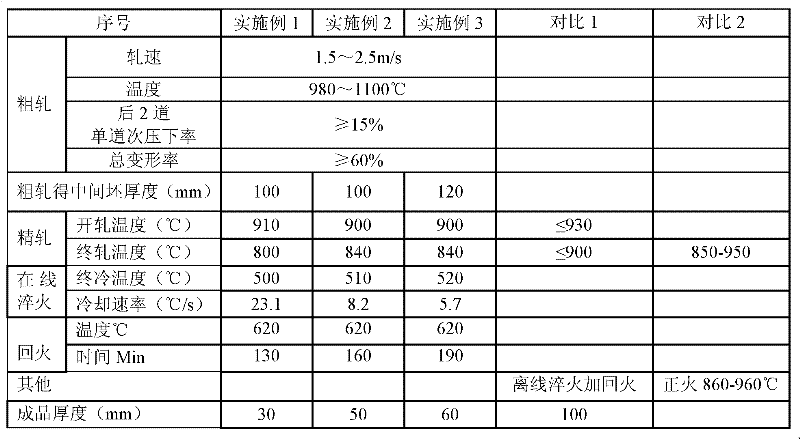

[0049] Within the chemical composition range described in the present invention, determine embodiment 1,2,3 chemical composition (wt%) as shown in table 1, wherein all control Fe is 97.7~98.6, N≤0.006, 0≤0.004, As≤ 0.04, Sn≤0.03, Sb≤0.02, the smelting and casting steps and control parameters of Examples 1, 2, and 3 are shown in Table 2, and the main rough rolling, finish rolling, and online quenching steps and control parameters of Examples 1, 2, and 3 As shown in Table 3, the mechanical properties of the finished 420MPa steel plate are shown in Table 4. The typical metallographic structure obtained is acicular ferrite + granular bainite + a small amount of massive ferrite.

[0050] In Tables 1, 2, and 3, comparison 1 is the document "Research and Development of High-strength Ship Plate NVD(E) 420 Steel Plate" disclosed on pages 13 to 17 of the 4th issue of "Wide and Heavy Plate" magazine in 2010, and comparison 2 is the publication number CN101643885 patent documents.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com