Production process of high-toughness high-wear-resistance stainless bearing steel bearing parts

A stainless bearing and production process technology, applied in the field of metal materials, can solve the problems of long time, high cost, inability to obtain parts with uniform structure, etc., and achieve the effect of reducing production cost, good toughness of the core, and increasing service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0023] The raw material used in the present invention is 9Cr18 or 9Cr18Mo stainless steel bearing steel that meets the national standard.

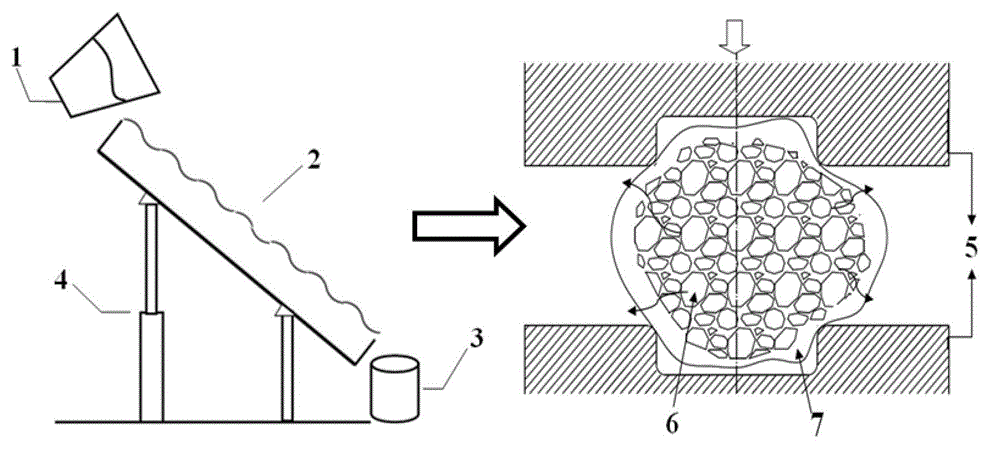

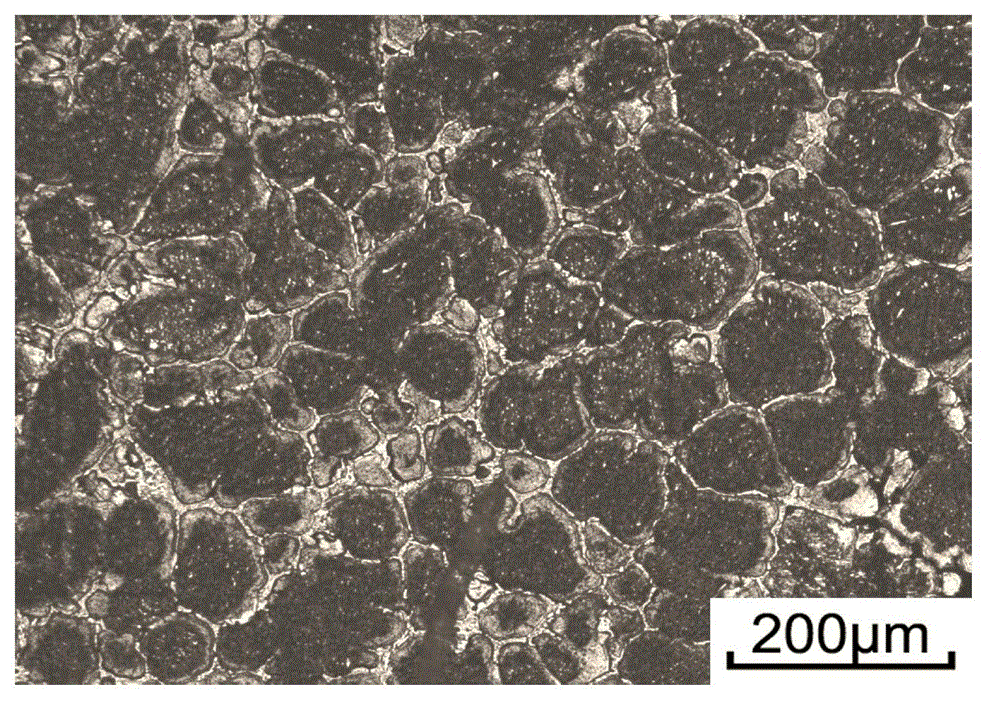

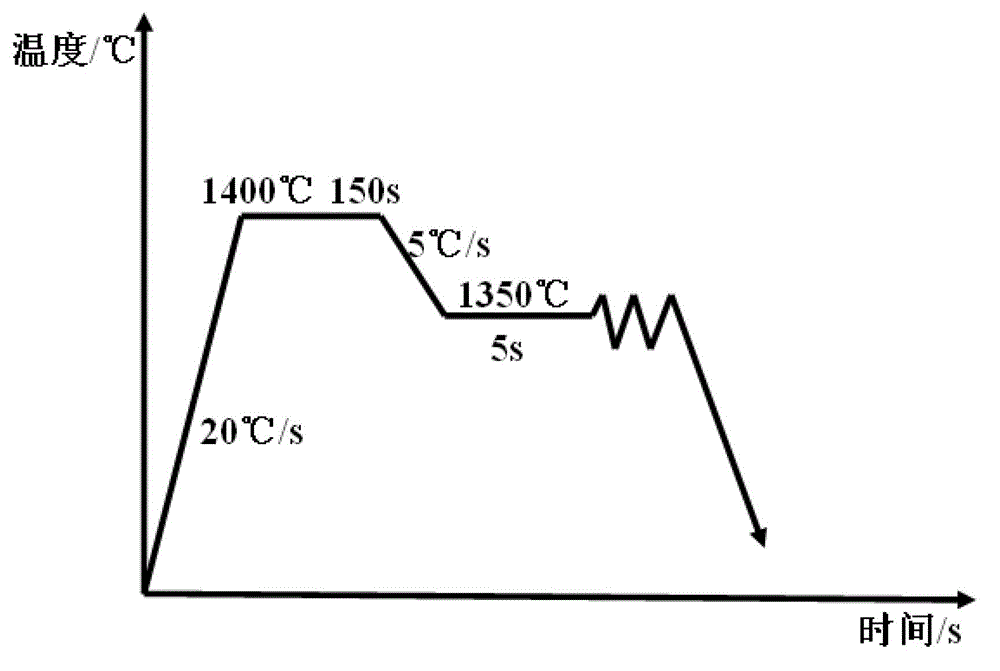

[0024] The semi-solid billet preparation device consists of a melting device, a wave-shaped inclined cold plate, and a collecting crucible, such as figure 1 Shown (1. Holding furnace; 2. Wave-shaped inclined plate; 3. Collection crucible; 4. Adjustable support; 5. Mold; 6. Solid phase; 7. Liquid phase). The specific process of billet preparation is as follows: heat the stainless bearing steel with the composition shown in Table 1 in an intermediate frequency induction furnace until it melts, and when the temperature rises to 1700°C, tilt the furnace body by adjusting the handle to make the molten steel flow through the wave-shaped inclined The cold plate is finally gathered in the collecting crucible...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com