Large-thickness and high-strength steel plate applicable to low temperature and manufacturing method thereof

A high-strength steel plate and manufacturing method technology, applied in the field of large-thickness, high-strength steel plate manufacturing, to achieve the effects of good lamellar tear resistance, simplified production process, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

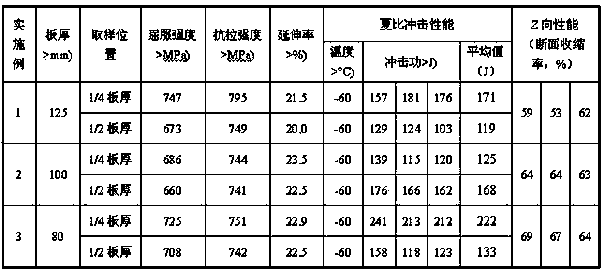

Embodiment 1

[0035] The thickness of the large-thickness, high-strength steel plate suitable for use at low temperatures involved in this example is 125 mm, and its chemical composition is calculated by mass percentage: C: 0.12%, Si: 0.17%, Mn: 0.96%, P: 0.005% , S: 0.002%, Cr: 0.42%, Mo: 0.44%, Ni: 1.4%, Cu: 0.22%, Al: 0.072%, V: 0.042%, Nb: 0.024%, Ti: 0.0038%, N: 0.0055% , B: 0.0011%, the balance is Fe and unavoidable impurity elements.

[0036] The manufacturing process of the 125mm-thick large-thickness and high-strength steel plate suitable for use at low temperature is to configure the smelting raw materials according to the chemical composition of the above-mentioned finished steel plate, and then sequentially carry out KR molten iron pretreatment, converter smelting, LF refining, and RH vacuum degassing To obtain molten steel with high purity, the continuous casting slab with a thickness of 370mm is continuously cast by the continuous casting machine. The continuous casting slab ...

Embodiment 2

[0040] The thickness of the large-thickness, high-strength steel plate suitable for use at low temperatures involved in this example is 100mm, and its chemical composition is calculated by mass percentage: C: 0.14%, Si: 0.25%, Mn: 1.10%, P: 0.007% , S: 0.0009%, Cr: 0.52%, Mo: 0.49%, Ni: 0.98%, Cu: 0.22%, Al: 0.038%, V: 0.04%, Nb: 0.024%, Ti: 0.013%, N: 0.0035% , B: 0.0018%, the balance is Fe and unavoidable impurity elements.

[0041] The manufacturing process of the 100mm thick large-thickness and high-strength steel plate suitable for use at low temperature is to configure the smelting raw materials according to the above chemical composition, and then carry out KR molten iron pretreatment, converter smelting, LF refining, and RH vacuum degassing to obtain pure steel. High-strength molten steel, and then the continuous casting slab with a thickness of 370mm is continuously cast by the continuous casting machine. The continuous casting slab meets the requirements of central ...

Embodiment 3

[0045] The thickness of the large-thickness, high-strength steel plate suitable for use at low temperatures involved in this example is 80mm, and its chemical composition is calculated by mass percentage: C: 0.08%, Si: 0.19%, Mn: 1.09%, P: 0.009% , S: 0.0014%, Cr: 0.38%, Mo: 0.37%, Ni: 1.13%, Cu: 0.24%, Al: 0.032%, V: 0.037%, Nb: 0.025%, Ti: 0.011%, N: 0.0032% , B: 0.0010%, the balance is Fe and unavoidable impurity elements.

[0046] The manufacturing process of the 80mm-thick large-thickness and high-strength steel plate suitable for use at low temperature is to configure the smelting raw materials according to the above chemical composition, and then carry out KR molten iron pretreatment, converter smelting, LF refining, and RH vacuum degassing to obtain pure steel. High-strength molten steel, and then the continuous casting slab with a thickness of 370mm is continuously cast by the continuous casting machine. The continuous casting slab meets the requirements of central s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com