Low-alloy extra-thick structure steel plate with the thickness being 400-610 mm and manufacturing method thereof

A structural steel plate, low alloy technology, applied in the field of steel plate manufacturing, can solve the problems of not fully meeting the needs of the industry development, not mentioning the flaw detection performance of the steel plate, and the thickness of the base blank and the steel plate being small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

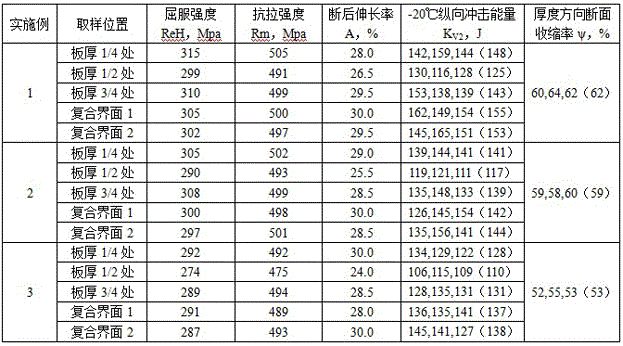

Embodiment 1

[0034] The thickness of the steel plate in this embodiment is 450mm, and its chemical composition is calculated by weight percentage: C: 0.12%, Si: 0.22%, Mn: 1.52%, P: 0.006%, S: 0.0008%, Al: 0.032%, Nb: 0.035%, V: 028%, Ti: 0.015%, Ni: 0.22%, Cu: 0.05%, H: 0.00010%, O: 0.0009%, N: 0.0032%, Pb: 0.0012%, Sn: 0.0025%, As: 0.0035%, Sb: 0.0015%, Bi: 0.002%, the balance is Fe and unavoidable impurity elements.

[0035] The manufacturing process of the steel plate is as follows:

[0036] Production process: steelmaking→continuous casting→base billet compounding→composite billet heating→compound billet rolling→steel plate slow cooling→steel plate flaw detection→steel plate normalizing→finishing→inspection→storage.

[0037] The specific operation of the main process is as follows:

[0038] Base billet steelmaking and continuous casting processes mainly reduce S, P, H, O and N elements in steel through KR molten iron pretreatment, slag removal treatment after converter smelting, RH ...

Embodiment 2

[0046] The thickness of the steel plate in this embodiment is 500mm, and its chemical composition is calculated by weight percentage: C: 0.13%, Si: 0.24%, Mn: 1.55%, P: 0.005%, S: 0.0005%, Al: 0.034%, Nb: 0.040%, V: 032%, Ti: 0.016%, Ni: 0.21%, Cu: 0.10%, H: 0.00008%, O: 0.0008%, N: 0.0036%, Pb: 0.0002%, Sn: 0.0030%, As: 0.0050%, Sb: 0.0020%, Bi: 0.0010%, the balance is Fe and unavoidable impurity elements.

[0047] The manufacturing process of the steel plate is as follows:

[0048] Production process: steelmaking→continuous casting→base billet compounding→composite billet heating→compound billet rolling→steel plate slow cooling→steel plate flaw detection→steel plate normalizing→finishing→inspection→storage.

[0049] The specific operation of the main process is as follows:

[0050] Base billet steelmaking and continuous casting processes mainly reduce S, P, H, O and N elements in steel through KR molten iron pretreatment, slag removal treatment after converter smelting, RH...

Embodiment 3

[0058] The thickness of the steel plate in this embodiment is 610mm, and its chemical composition is calculated by weight percentage: C: 0.14%, Si: 0.20%, Mn: 1.55%, P: 0.006%, S: 0.0005%, Al: 0.030%, Nb: 0.035%, V: 035%, Ti: 0.018%, Ni: 0.23%, Cu: 0.06%, H: 0.00006%, O: 0.0008%, N: 0.0032%, Pb: 0.0001%, Sn: 0.0020%, As: 0.0030%, Sb: 0.0022%, Bi: 0.0012%, and the balance is Fe and unavoidable impurity elements.

[0059] The manufacturing process of the steel plate is as follows:

[0060] Production process: steelmaking→continuous casting→base billet compounding→composite billet heating→compound billet rolling→steel plate slow cooling→steel plate flaw detection→steel plate normalizing→finishing→inspection→storage.

[0061] The specific operation of the main process is as follows:

[0062] Base billet steelmaking and continuous casting processes mainly reduce S, P, H, O and N elements in steel through KR molten iron pretreatment, slag removal treatment after converter smelting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com