Overlaying manufacture repair technology for roll forging die

A technology of manufacturing process and mold surfacing welding consumables, which is applied in the field of hot forging rotary mold surfacing welding manufacturing and repair, and can solve problems such as cold and heat fatigue, cracking, and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

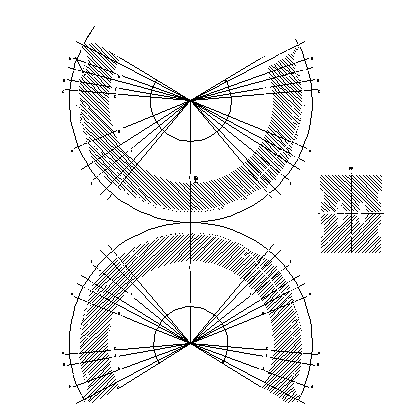

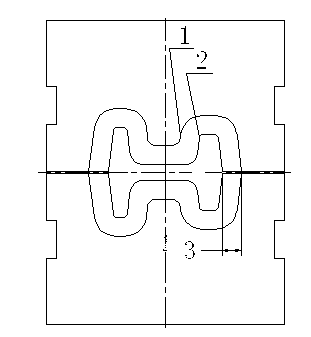

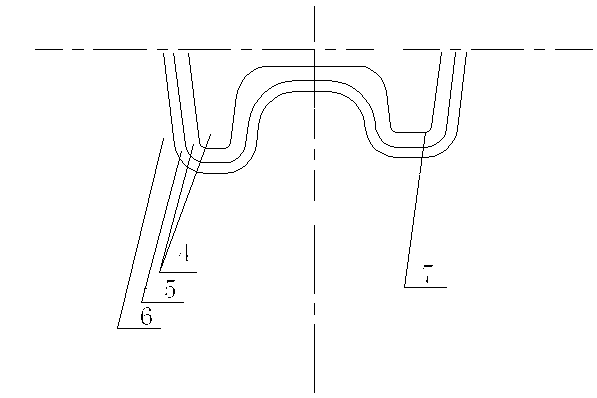

Image

Examples

Embodiment Construction

[0030] The concrete method of roll forging die build-up welding manufacturing technique of the present invention comprises the following processing steps:

[0031] ⑴. First, select low heat-resistant steel 5CrMnMo and 5CrNiMo die steel as the base material, heat treatment hardness 34-42HRC, and expand the cavity size of long rod forgings by 11-20mm to make a mold, and preheat the mold to 550°C, keep warm for 10 hours. 5CrMnMo and 5CrNiMo have low cost, uncomplicated and mature heat treatment process, and have good cutting performance, impact resistance, crack resistance and moderate hardenability. But often, high temperature wear resistance, cold and heat fatigue resistance, thermal stability, high temperature oxidation resistance are poor.

[0032] ⑵, Secondly, choose the hardness HRC34~42 surfacing welding metal welding materials, and surfacing the bottom layer with a thickness of 3~6mm in the mold cavity. Hardness HRC34~42 surfacing welding metal welding consumables are R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com