Anorganolith/slag wool thin-plastered outer wall thermal insulation system and construction technology

A technology for external wall thermal insulation and thin plastering, which is used in thermal insulation, covering/lining, building components, etc., can solve the problems of poor thermal insulation effect, poor fire performance, and poor durability, and achieves good surface crack resistance and thermal insulation. Excellent performance and excellent wind pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

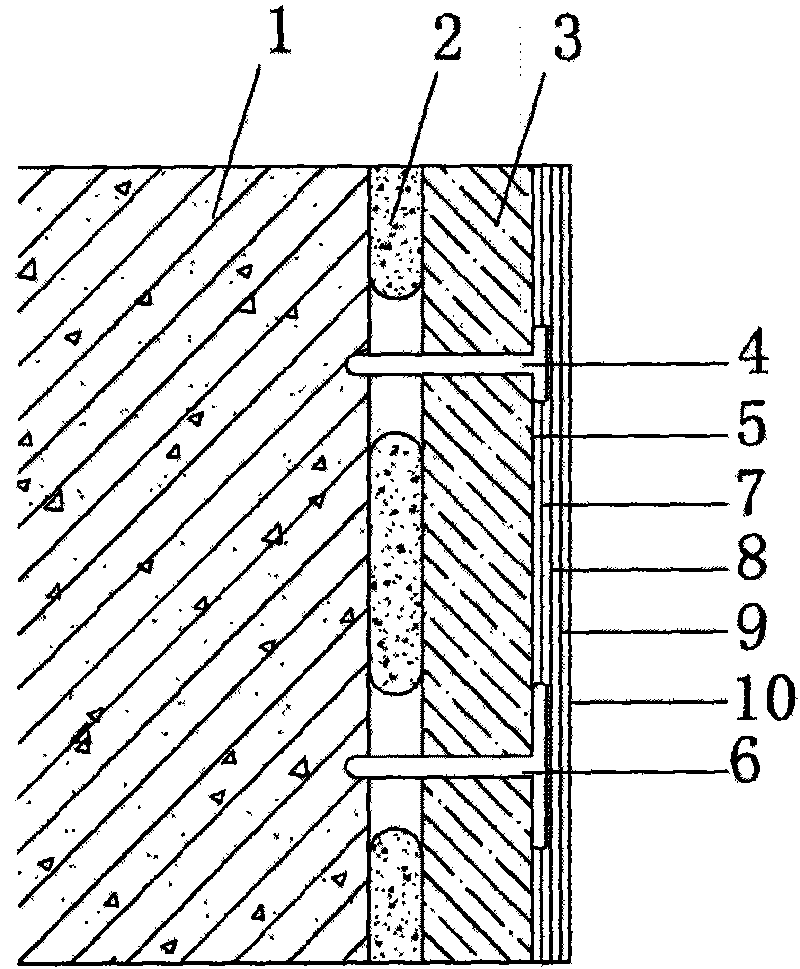

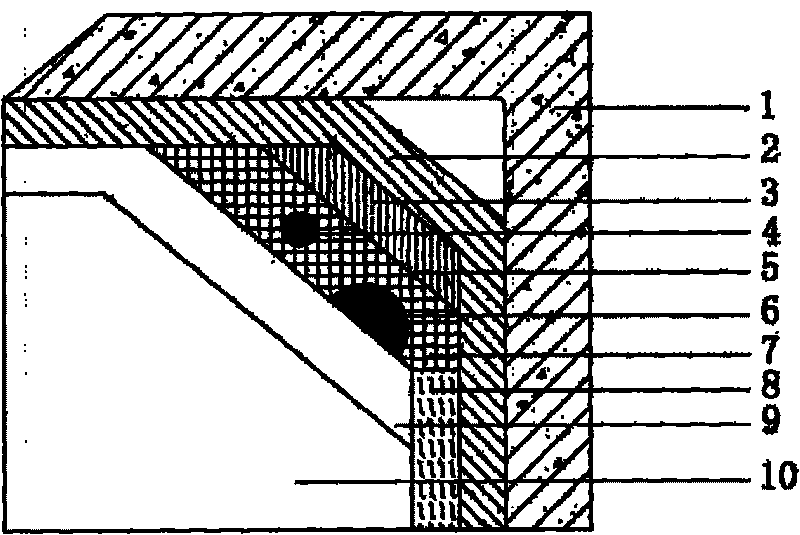

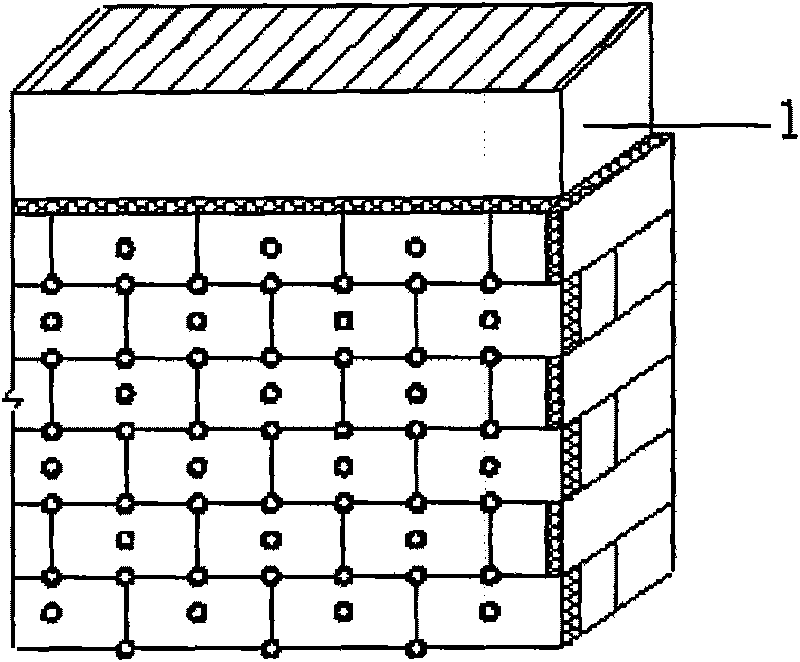

[0047] An inorganic rock / mineral wool thin plastering external wall thermal insulation system, the system mainly consists of a base layer 1, a bonding layer 2, a rock / mineral wool thermal insulation layer 3, a rock / mineral wool thermal insulation board fixing anchor bolt 4, and a metal gasket Type integrated anchor bolt 6, reinforced mesh cloth or hot-dip galvanized steel wire mesh, anti-crack protection layer and finishing layer, such as Figure 1-2 shown.

[0048] Such as Figure 6 As shown, the fixed anchor bolt 4 of the rock / mineral wool insulation board is made up of a plastic disc 41 with a diameter of 50-80mm, a metal nail 42, and a hole 43 filled with mortar.

[0049] Such as Figure 7 shown. The metal gasket type integrated anchor bolt 6 is composed of a plastic disc 61 with a diameter of 100-300mm, a metal nail 62, a mortar filling hole 63, and a metal gasket 64.

[0050] The construction technique of this system embodiment:

[0051] 1. Basic treatment

[0052]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com