Composite material thermal insulation plate

A composite material and thermal insulation board technology, applied in thermal insulation, thermal insulation, pipeline protection and other directions, can solve the problems of high cost, cracking, affecting the progress of the project, etc., and achieve the effects of strong self-breathing function, simple production process and low investment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The raw materials of the composite insulation board of the present invention are waste phenolic foam powder, fly ash, expanded perlite, mineral wool, glass wool, sepiolite, palygorskite, neutral water glass as an inorganic binder, and organic The methyl cellulose of binding agent and water form, and raw material component is prepared by following mixing ratio (weight %):

[0038] Waste phenolic foam powder-15%; fly ash-7%; perlite-15%; sepiolite-10%; palygorskite-5%; mineral wool-10%; water glass-2.75%; Cellulose - 0.25%; Water - 35%.

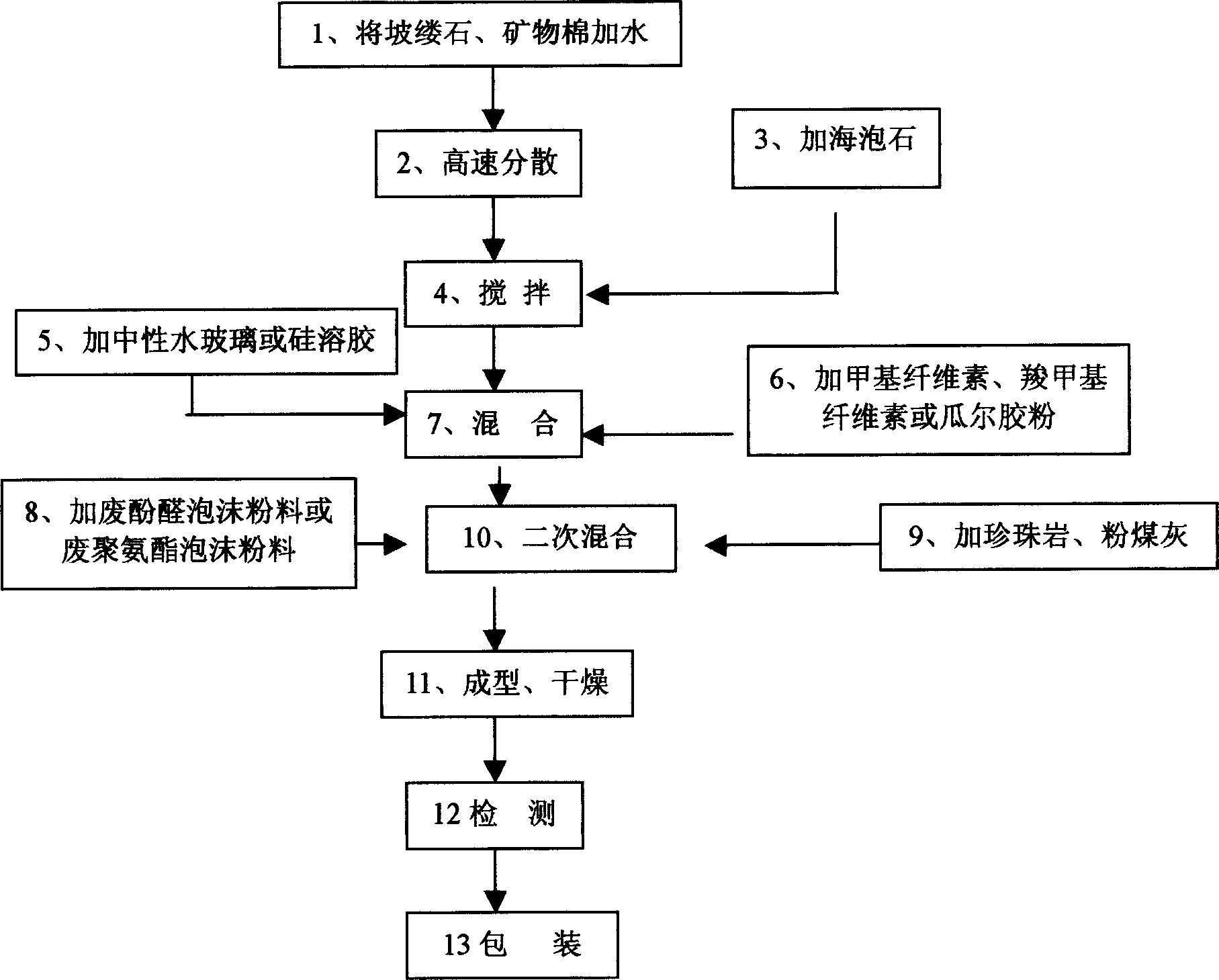

[0039]Add water to palygorskite and mineral wool for high-speed dispersion, add sepiolite for stirring, then add neutral water glass and methyl cellulose to mix, then add waste phenolic foam powder, fly ash and perlite Mixing, final injection molding, forming and drying are made into the composite material insulation board of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com