Method for preparing mineral wool by using ferronickel dross sensible heat

A technology of ferronickel and slag, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of energy consumption reduction, waste, heat waste and other problems of mineral wool smelting, and achieve reduced smelting energy consumption, smelting cost reduction, and low service life Effect

Inactive Publication Date: 2008-10-29

杨铧 +1

View PDF0 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This smelting method does not use the molten blast furnace slag that has just flowed out of the blast furnace to directly produce mineral wool, but waits for the blast furnace slag to cool down and then enters the mineral wool cupola for smelting. Therefore, this smelting method should be repeated twice. The energy used in the melting process is also a recurring energy consumption

At the same time, the coke fuel used in the mineral wool cupola is also a secondary energy source formed by complex processes such as selection, washing, blending, and smelting of raw coking coal. The production of one ton of coke requires about 2.7 tons of raw coking coal. The unit price is 1 to 2 times that of coal, but the calorific value of 1 ton of coke is only about 57 to 60% of the calorific value of raw coking coal consumed to produce 1 ton of coke. The energy conversion efficiency of the process of using raw coking coal to produce coke is relatively low

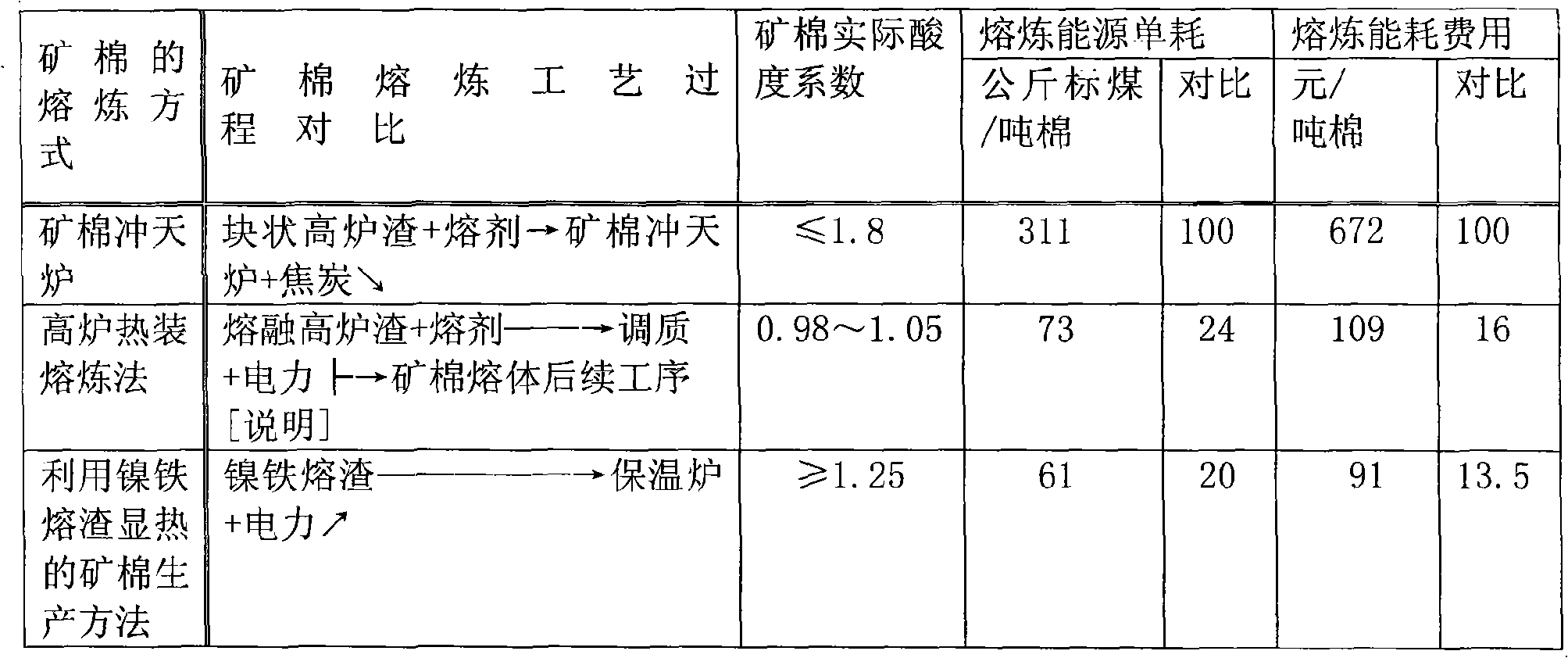

The thermal efficiency of the original mineral wool cupola is very low (25-40%), plus the use of massive cold blast furnace slag and coke as raw materials and fuel, so the mineral wool cupola smelting is a waste of energy.

Although at the beginning of this century there appeared a method of producing mineral wool fibers by blast furnace hot-charging smelting that did not use coke at all, which greatly reduced the energy consumption of mineral wool smelting (70% lower than the smelting energy consumption of coke and mineral wool cupola furnaces). %), but this method has a relatively fatal shortcoming: its main raw material - pig iron blast furnace slag is alkaline slag, its acidity coefficient is less than 1.0, in order to meet the requirements of mineral wool fiber forming on the chemical composition of the melt It is necessary to add acid flux to temper the basic blast furnace slag, so as to increase the acidity coefficient of the melt to the range of 1.1-1.2 which is the minimum requirement for mineral wool fiber formation

However, the practice in recent years has proved that the melting and homogenization of the flux is very difficult. In actual production, the highest acidity coefficient can only reach about 1.05. Although this mineral wool can meet the minimum requirements for the production of mineral wool products, but It is very unstable in terms of water resistance, fiber elasticity, brittleness, fiber length, etc., and it is difficult to meet the quality requirements of mineral wool products stably in terms of quality.

For many years, in the field of mineral wool production, mineral wool cupolas have always used cold massive blast furnace slag as the main raw material. Sensible heat not used

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the technical filed of mineral cotton production, which is a method for producing mineral cotton by using the sensible heat of ferronickel slag. The method includes the following steps: laterite-nickel ore is adopted as basic material, and the ferronickel slag with the temperature of 1450 to 1500 DEG C and acidity coefficient being equal to or more than 1.25 is poured into a power thermal insulation furnace with the capacity being 15 tons without adding any fusing agent; the temperature of melts is adjusted and kept within the range of 1350 to 1400 DEG C; then the melts with adjusted temperature are correctly led to a four-roller centrifugal machine by a water-cooling controllable head piece and a diversion trench so as to lead the ferronickel slag to be directly transformed into the mineral cotton fiber with high quality. Electrode materials in the power thermal insulation furnace are metal or carbon.

Description

technical field The invention relates to the technical field of mineral wool production, in particular to a method for producing mineral wool by utilizing the sensible heat of ferronickel slag. Background technique The traditional technology of mineral wool smelting is a mineral wool cupola smelting technology with coke as fuel and lump blast furnace slag as the main raw material, which is also a mineral wool smelting method that is still widely used at home and abroad. This smelting method does not use the molten blast furnace slag that has just flowed out of the blast furnace to directly produce mineral wool, but after the blast furnace slag is cooled into lumpy slag, it is then smelted in the mineral wool cupola, so this smelting method should be repeated twice. The energy used in the melting process also belongs to the energy of repeated consumption. At the same time, the coke fuel used in the mineral wool cupola is also the secondary energy formed by the raw coking coa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C03B37/00

Inventor 杨铧吴军

Owner 杨铧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com