Tab track fire-rated wall assembly with dynamic movement

a technology of fire-rated walls and tabs, which is applied in the direction of walls, constructions, building components, etc., can solve the problems of drywall slanting away from the framing, affecting the stability of the wall and the building, and requiring extra labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Track Framing Assemblies

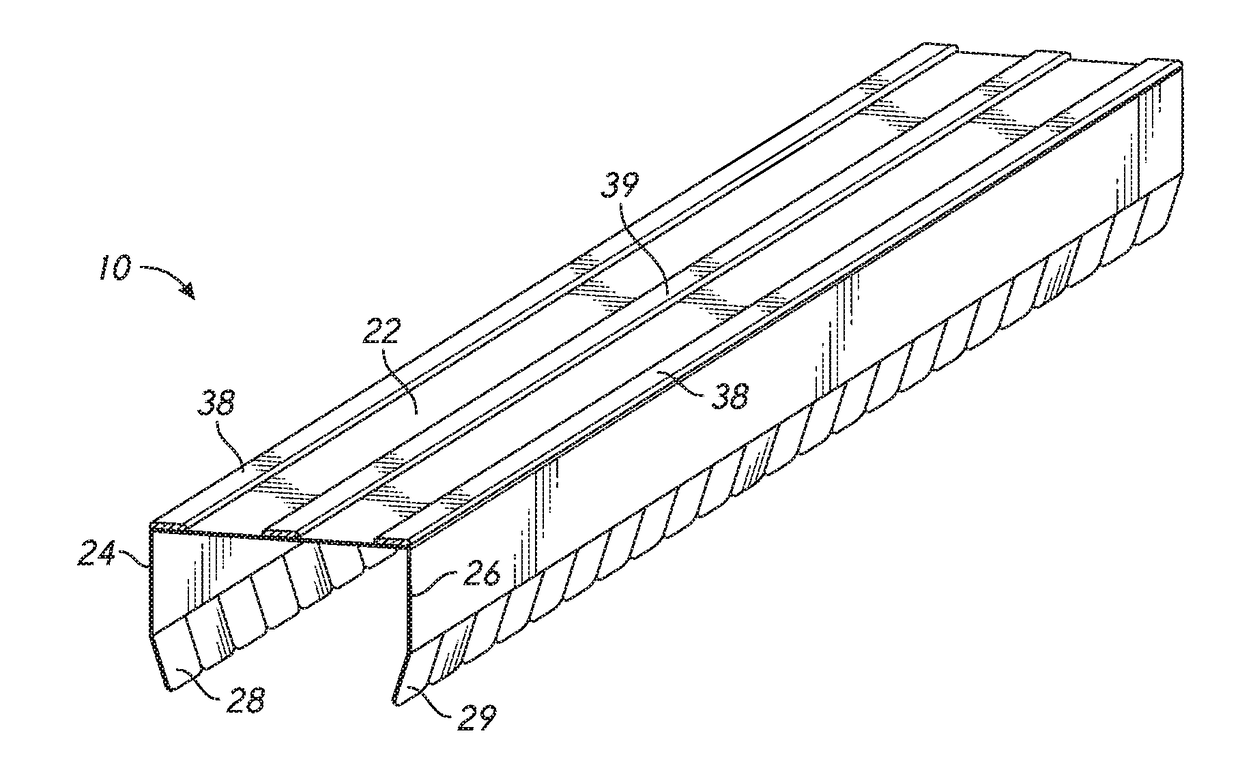

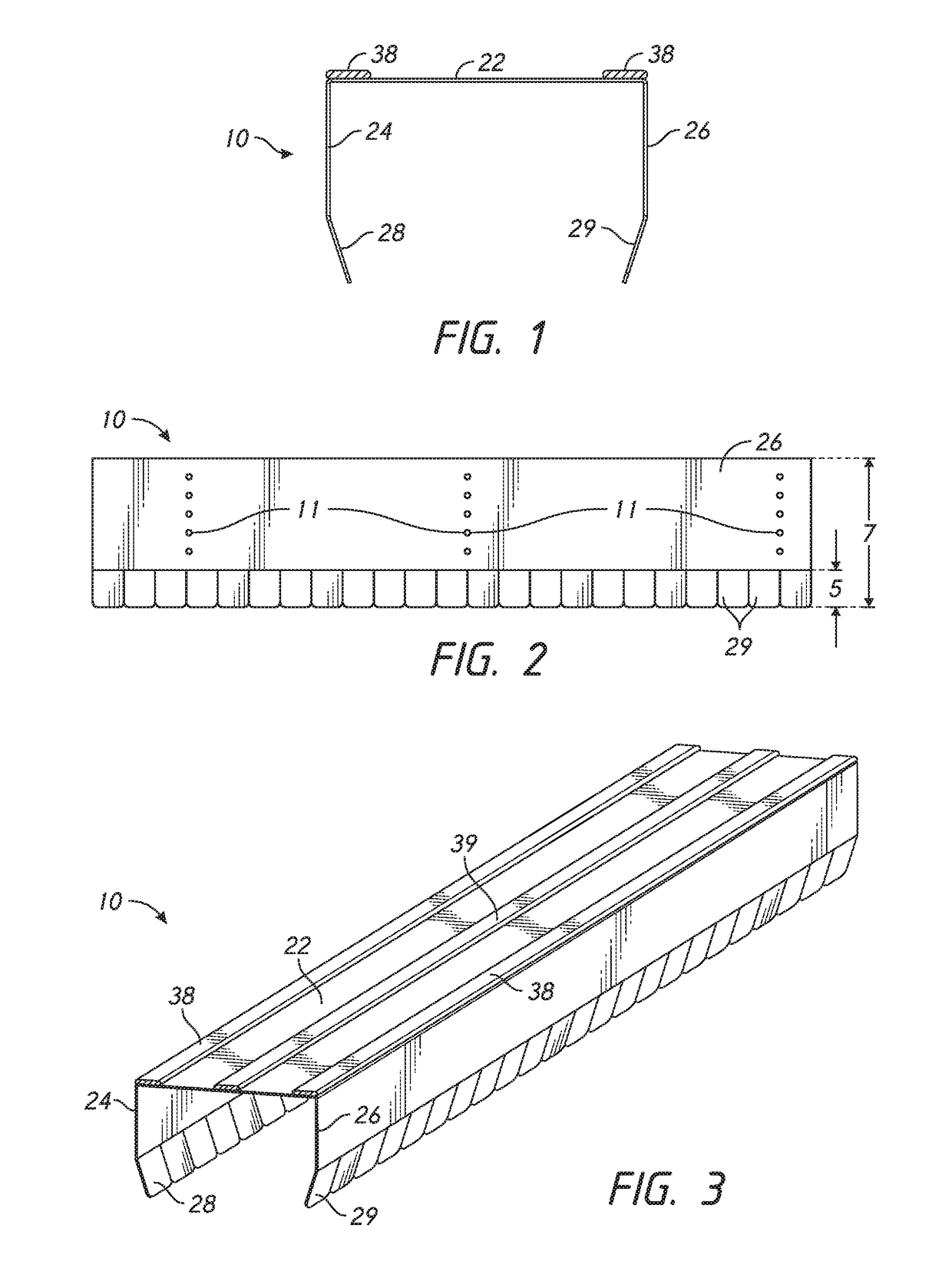

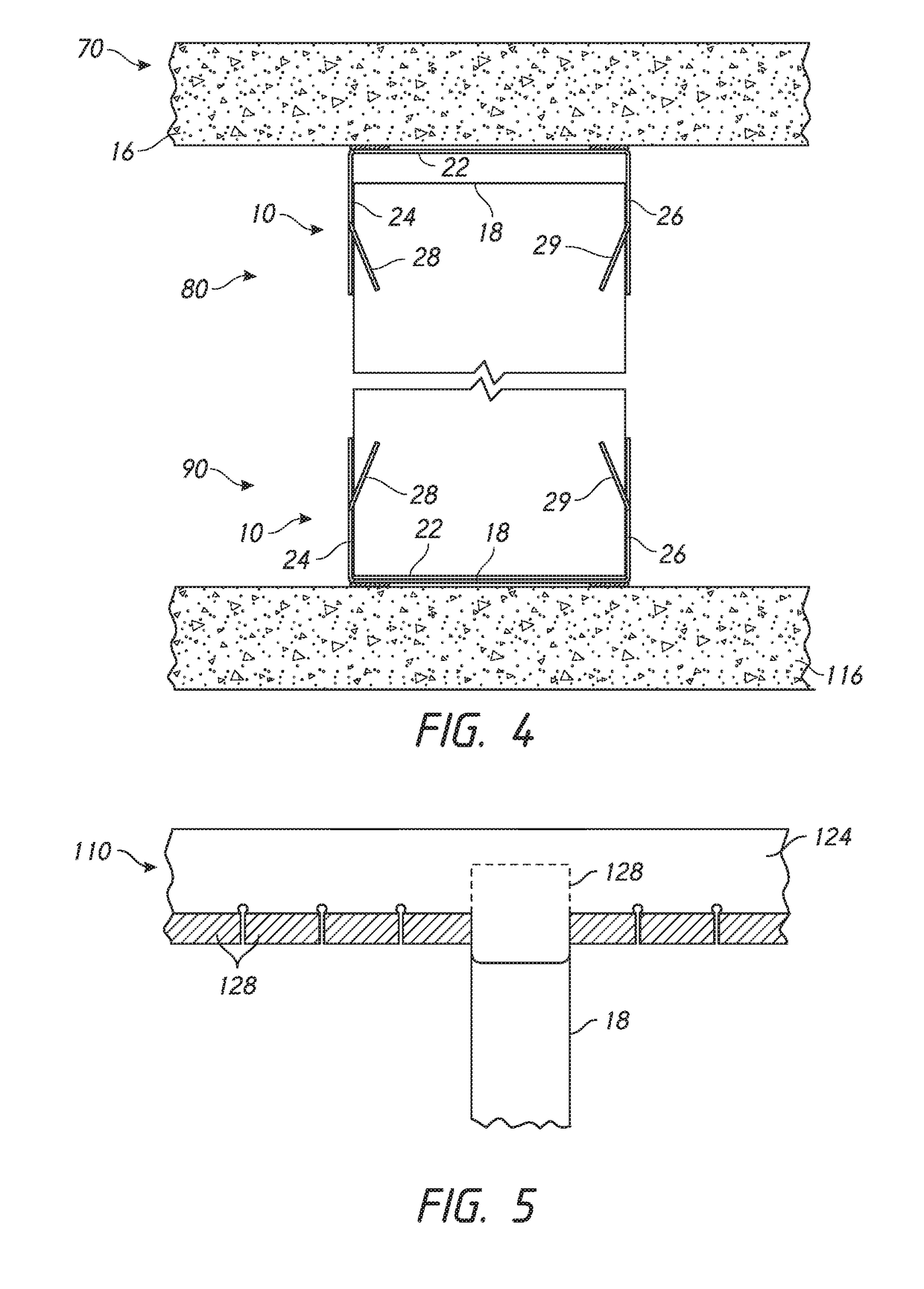

[0067]Several preferred embodiments provide a way to secure metal studs to the header track or bottom track without using mechanical screw fasteners. The C- or U-shaped header or bottom track includes a plurality of slits in one or both flanges of the track that form a plurality of tabs in the flanges of the track adjacent the free edge of the flanges. The slits extend partially up the legs or flanges of the track so that the bulk of the track is a solid uninterrupted C- or U-shape profile. The track can, in some embodiments, have fire-retardant material such as intumescent strips added to the surface of the back web of the track to provide fire rated wall assemblies according to UL-2079.

[0068]Referring to FIGS. 1-3, a first embodiment of a track 10 comprises a web 22 and two side flanges 24, 26. A lower end of each of the side flanges 24, 26 comprises a plurality of tabs 28, 29 that may be folded or bent inward towards the web 22 to secure a metal stud, as d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electrical resistance | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Sound absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com