SiO2 aerogel/inorganic cotton compound thermal insulation felt and preparation method thereof

A technology of composite thermal insulation and inorganic cotton, which is applied in the field of SiO2 airgel/inorganic cotton composite thermal insulation felt and its normal pressure drying preparation, can solve the problems of different process links, high drying temperature, and no thermal conductivity, etc., to achieve The effect of wide application prospect, strong hydrophobicity and excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

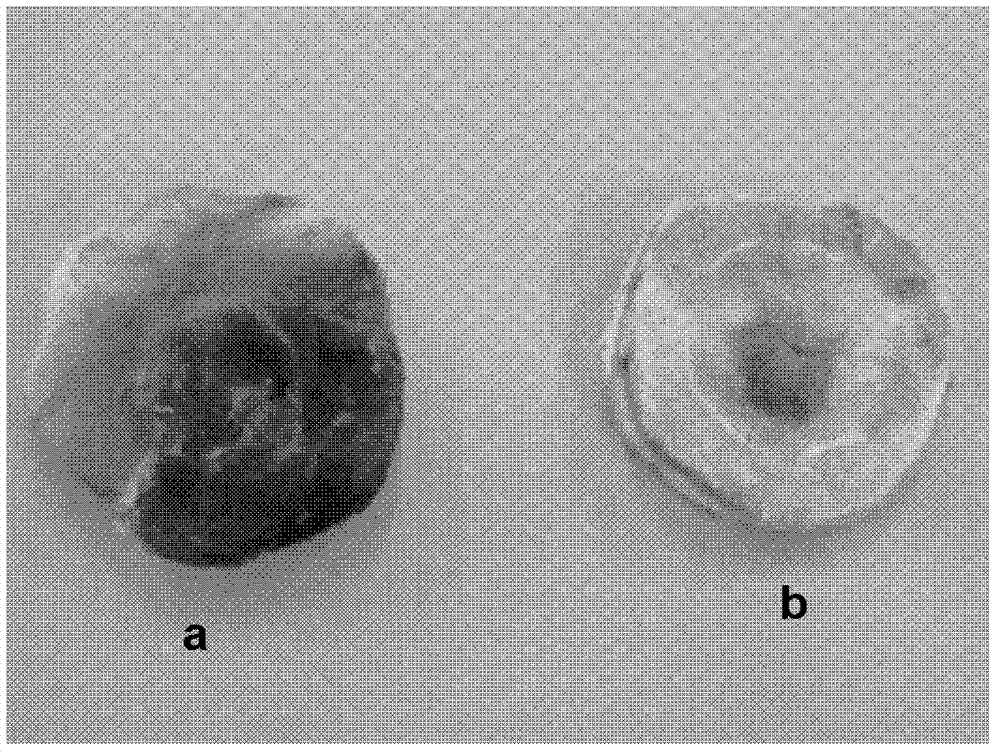

Image

Examples

Embodiment 1

[0045] The preparation density is 0.23g / cm 3 SiO 2 Airgel / Glass Wool Composite Thermal Insulation Blanket

[0046] ① Preparation of alumina sol:

[0047] Weigh 20.4g of aluminum isopropoxide, add 200ml of deionized water and stir at 80°C until the aluminum isopropoxide is completely dissolved, then add 0.3ml of concentrated nitric acid, and continue stirring for 3 hours to form alumina sol.

[0048] ② Preparation of silicic acid solution:

[0049] Measure 60ml industrial water glass (modulus=3.38, mSiO 2 %=26, ρ=1.37g / ml) is mixed with 240ml deionized water, after stirring evenly, carry out ion exchange by strongly acidic styrene cation exchange resin, obtain the silicic acid solution of pH=2~3.

[0050] ③Pre-coating treatment of glass wool:

[0051] Put 15.531g of glass wool in a high-temperature sintering furnace and calcinate at 500°C for 2 hours, take it out and weigh 14.426g; take 50ml of the prepared alumina sol and pour it on the pre-fired glass wool to make it ful...

Embodiment 2

[0059] The preparation density is 0.23g / cm 3 SiO 2 Airgel-Inorganic Cotton Composite Thermal Insulation Blanket

[0060] 1. Preparation of alumina sol: same as step 1 of Example 1;

[0061] ② Preparation of silicic acid solution:

[0062] Measure 30ml industrial water glass (modulus=3.38, mSiO 2 %=26, ρ=1.37g / ml) is mixed with 120ml deionized water, after stirring evenly, carry out ion exchange by strongly acidic styrene cation exchange resin, obtain the silicic acid of pH=2~3.

[0063] ③Pre-coating treatment of glass wool:

[0064] Put 18.890g of glass wool in a high-temperature sintering furnace at 500°C for 2 hours, take it out and weigh 16.854g; take 80ml of the prepared alumina sol and pour it on the pre-fired glass wool to make it fully adsorbed, and then Squeeze gently to squeeze out excess alumina sol, then put the glass wool pretreated by alumina sol into an oven, and dry at 80°C for 2 hours.

[0065] ④ Compounding of silicic acid solution and glass wool:

[00...

Embodiment 3

[0072] The prepared density is 0.27g / cm 3 SiO 2 Airgel / Glass Wool Composite Thermal Insulation Blanket

[0073] 1. Preparation of alumina sol: same as step 1 of Example 1;

[0074] ② Preparation of silicic acid solution:

[0075] Measure 40ml industrial water glass (modulus=3.38, mSiO 2 %=26, ρ=1.37g / ml) mixed with 160ml deionized water, after stirring evenly, carry out ion exchange by strongly acidic styrene cation exchange resin, obtain the silicic acid of pH=2~3.

[0076] ③Pretreatment of glass wool:

[0077] Put 16.957g of glass wool in a high-temperature sintering furnace at 500°C for 2 hours, take it out and weigh 15.846g; take 110ml of the prepared alumina sol and pour it on the pre-fired glass wool to make it fully adsorbed, and then Squeeze gently to squeeze out excess alumina sol, then put the pretreated glass wool into an oven and dry at 80°C for 2h.

[0078] ④ Compounding of silicic acid solution and glass wool:

[0079] Take 160ml of the prepared silicic ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com