Zipper slider with demountable pull tab

A zipper head and pull tab technology, applied in the field of zipper, can solve the problems of metal fatigue of shrapnel, large deformation of shrapnel, breakage, etc., and achieve the effects of avoiding metal fatigue, reducing deformation amplitude and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

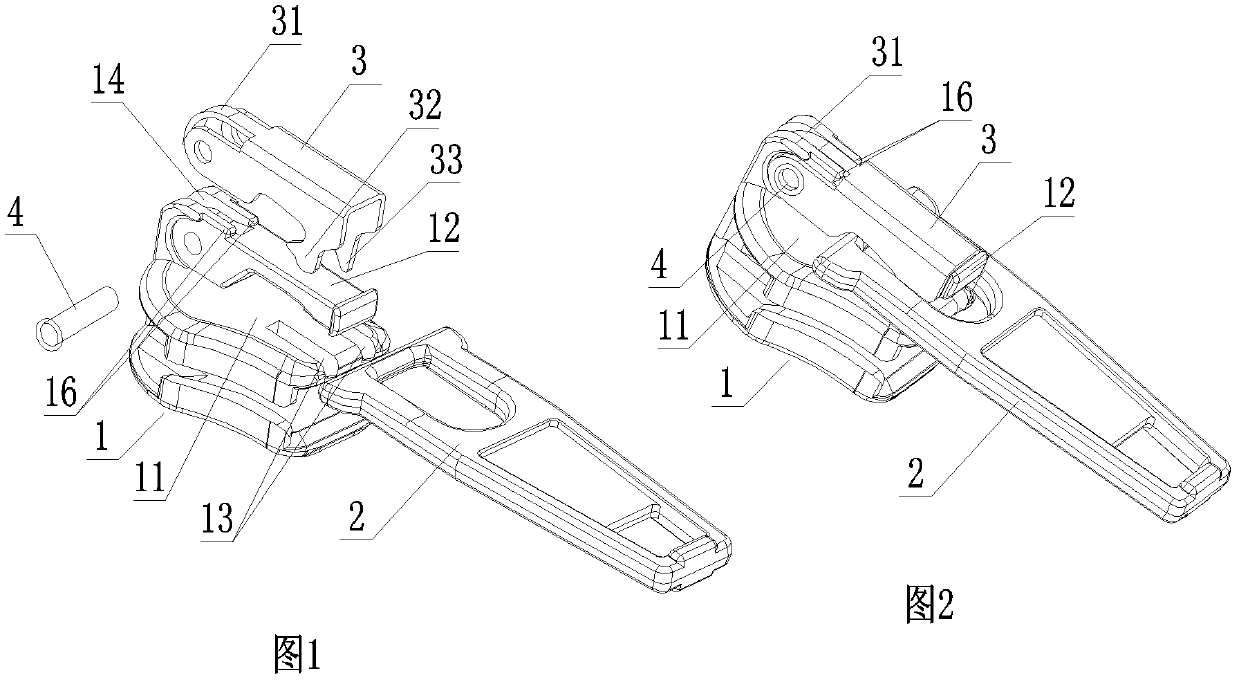

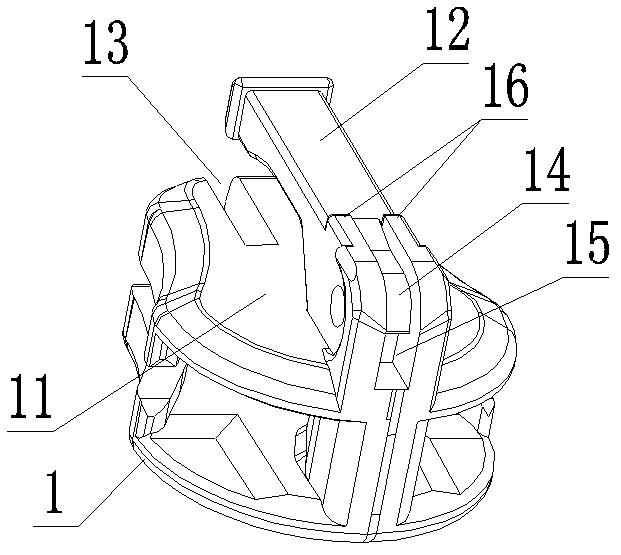

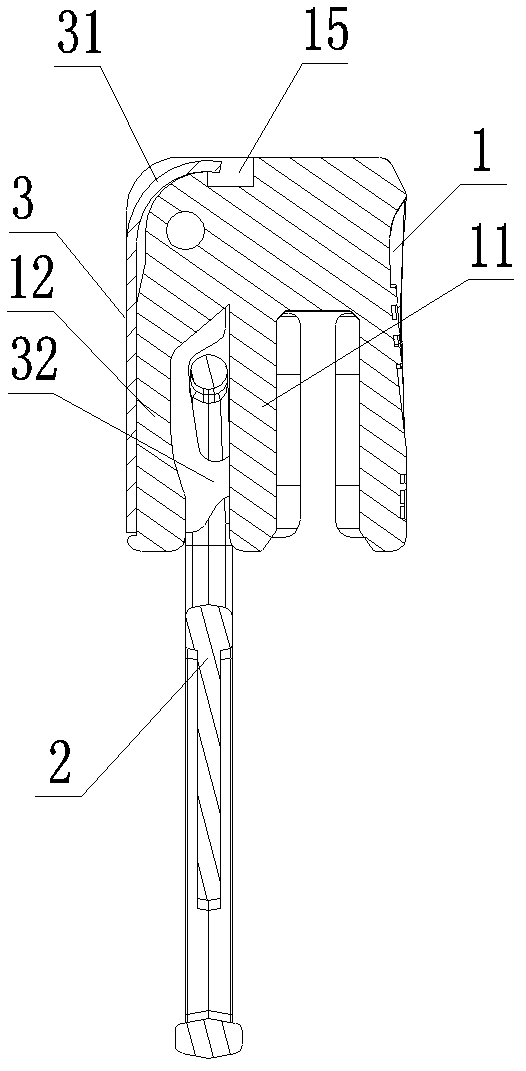

[0011] Such as Figure 1-4 As shown, a zipper puller with a detachable pull tab includes a slider body 1, a pull tab 2 and a hook 3. The upper slide plate 11 of the slider body 1 is formed with a pull nose 12, and the hook 3 is connected to the pull nose. The root of the hook 12 is hinged, and the hinged end of the horse hook 3 is formed with a shrapnel 31 that bends and extends toward the root of the pull nose 12. The two sides of the other end of the horse hook 3 are respectively formed with barbs 32 that can buckle the pull piece 2 and can be inserted. The insertion teeth 33 of the chain teeth, and the upper sliding plate 11 of the slider body 1 are respectively provided with slots 13 that can accommodate the barbs 32 and the insertion teeth 33 .

[0012] In this embodiment, the horse hook 3 is a groove-shaped cover, and the horse hook 3 is covered on the pull nose 12 . With the pin shaft 4 as the center of the circle, the inner surface of the elastic piece 31 is set as an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com