Vacuum gas-filling packaging machine used for fully-automatic hot forming

An inflatable packaging and thermoforming technology, which is applied to packaging, packaging, and transportation packaging under vacuum/special atmosphere. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

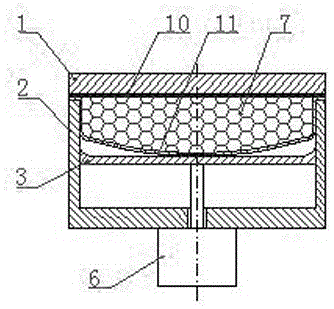

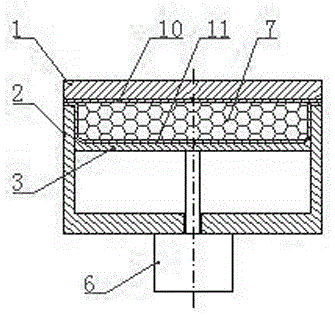

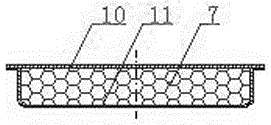

[0014] see Figure 4 ~ Figure 7 , the present invention is a fully automatic thermoforming vacuum inflatable packaging machine, comprising a lower film forming blister transfer mechanism, an upper film upper film blister transfer mechanism, a working surface 23, a heat-sealing studio 16 and a cutting mechanism, and the lower film forming The plastic-absorbing transmission mechanism is set at the front end of the working surface, and the plastic-absorbing transmission mechanism on the upper film is located above the middle of the working surface, and the heat-sealing studio is installed on the working surface corresponding to the rear of the plastic-absorbing transmission mechanism on the upper film. 16 and a cutting mechanism; the heat-sealing working chamber 16 is connected with vacuum equipment, and it is characterized in that the heat-sealing working chamber 16 includes a heat-sealing electric heating plate 1, a heat-sealing working lower chamber 2, a shaping mold 3 and a sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com