Blank of diamond type packing box for containing liquid and packing box

A packaging box, diamond-shaped technology, applied in the field of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

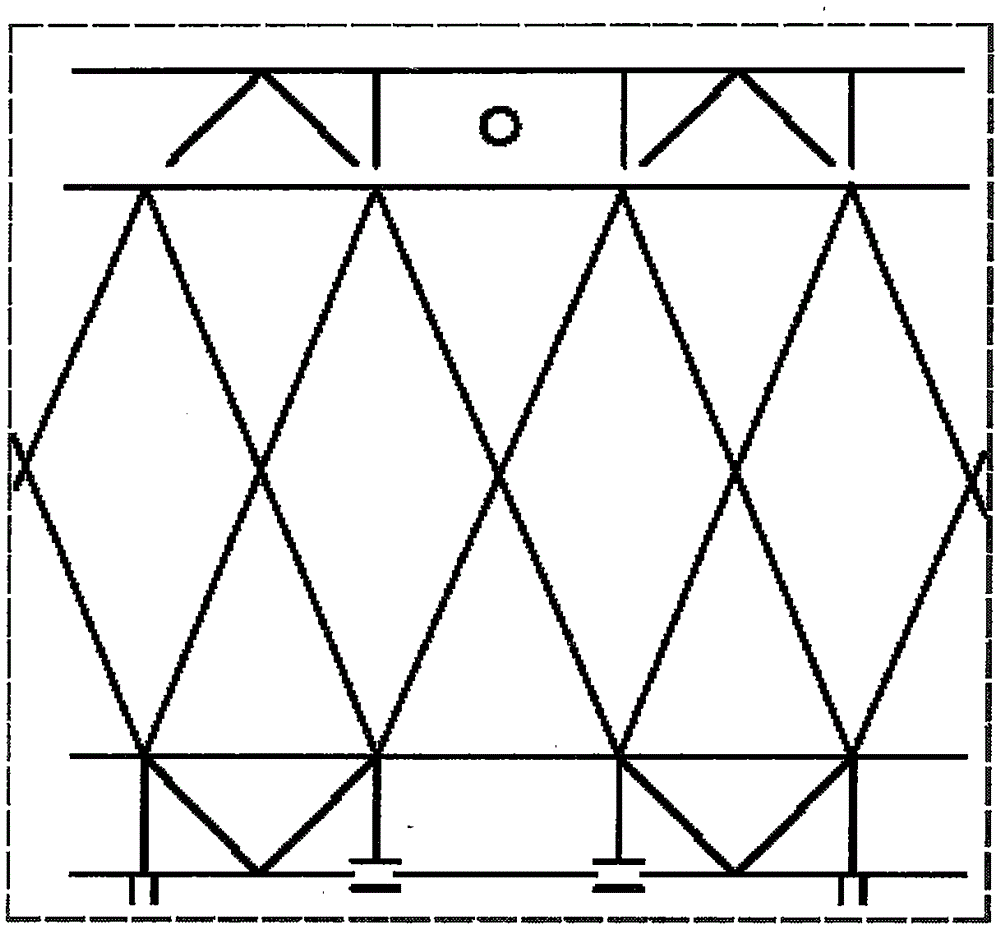

[0016] Embodiment 1, the blank material of the diamond-shaped packing box that is used to hold liquid, this blank material is as figure 1 shown.

[0017] exist figure 1 Among them, the blank in this embodiment is a sheet-shaped packaging material, and the shape, size, and thickness of the sheet-shaped packaging material are often related to the number of packaging boxes formed by the blank, the size and shape of the packaging box, and the packaging. Box thickness requirements and other factors are related.

[0018] In practical application, the shape of the sheet-shaped packaging material is generally rectangular, and the sheet-shaped packaging material can be used to form one packaging box, or multiple packaging boxes. figure 1 The blank shown in is the packaging material that can be formed into a box. In the following description, this embodiment is described by taking the packaging material forming one packaging box as an example, and the packaging materials forming mult...

Embodiment 2

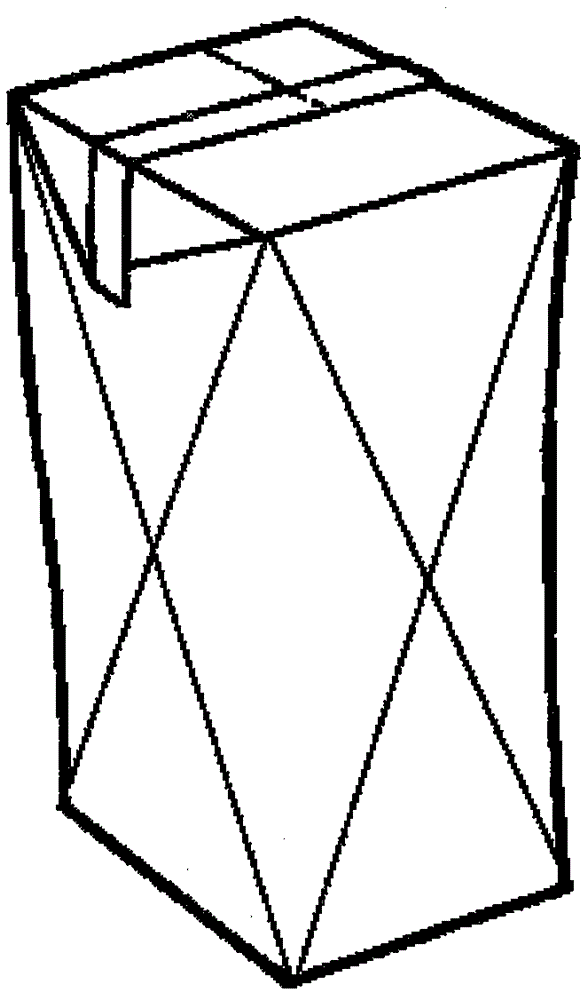

[0029] Embodiment 2, a diamond-shaped packing box for holding liquid.

[0030] Depend on figure 1The packaging box formed by the blank material in the figure 2 shown. Depend on figure 1 The process of forming the packaging box from the blank material can be as follows: first form the sealing seam on the side of the packaging box according to the two vertical creases at the left and right ends of the blank material, and then, according to the horizontal crease on the bottom side of the blank material (that is, the above-mentioned The fourth horizontal crease) forms the sealing seam of the lower bottom surface of the packaging box, cages the packaging box of the current shape, and makes the side of the packaging box of the current shape form a diamond shape (that is, the intersection of two diagonal lines protrudes outward) , and make the lower bottom surface form a rectangular shape (the two opposite right angles of the lower bottom surface can be bent inside the packaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com