Conveying method of heating furnace in continuous glass toughening furnace

A glass tempering and heating furnace technology, which is applied in glass tempering, glass transportation equipment, glass manufacturing equipment, etc., can solve problems such as easy deformation of the glass surface, achieve obvious effects, improve wave patterns, and increase production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

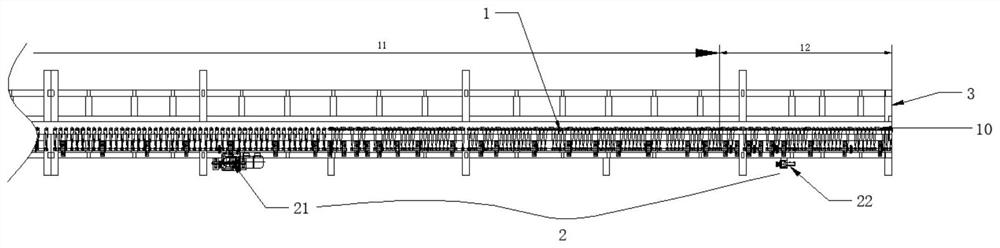

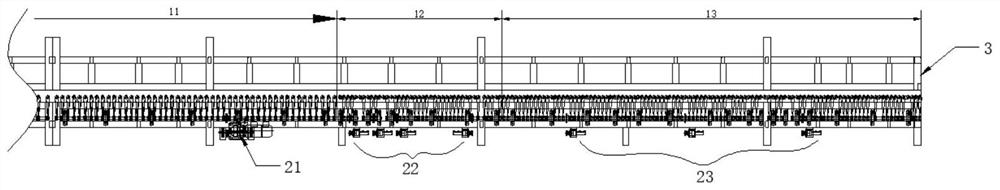

[0035] Such as figure 1Shown is a schematic structural view of a heating furnace in the prior art. The heating furnace of the continuous tempering furnace mainly includes a furnace body, a conveying line 1, a conveying mechanism 2, and a heating device (not shown in the figure); In the heating furnace part of the tempering furnace, an acceleration section 12 will be set near the furnace door 3. The conveyor line 1 of the heating furnace is divided into a flat delivery section 11 and an acceleration section 12. The transmission of the conveyor roller table 10 in the acceleration section is controlled separately by an acceleration motor 22 , The length of the accelerating section 12 matches the glass produced, generally slightly longer than the length of the glass. During specific use, the glass 4 passes through the horizontal conveying section 11 at a constant speed and is heated to the temperature required for tempering, and then the glass 4 as a whole enters the accelerating...

Embodiment 2

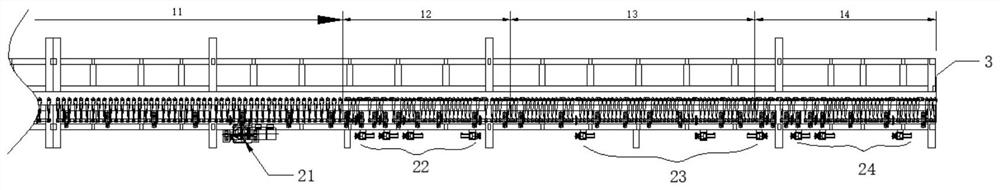

[0056] Compared with Embodiment 1, in this embodiment, as image 3 As shown, a sub-acceleration section 14 is added behind the fast section 13, and the sub-acceleration section 14 is controlled by the sub-acceleration motor 24 to convey the speed.

[0057] When this embodiment is actually used, it is divided into two situations, such as Figure 6 As shown, when the thickness of the glass is >2.5mm, the flat speed section 11, the acceleration section 12, and the fast section 13 all run at a flat speed, and the glass travels to the sub-acceleration section 14, and the speed changes after entering the sub-acceleration section 14 as a whole, and the transmission speed is accelerated to leave Sub-acceleration section 14 comes out of the furnace, and after the glass leaves sub-acceleration section 14, sub-acceleration section 14 returns to its original speed. For thicker glass, the running speed of the roller conveyor has little effect on glass deformation, and only sub-acceleration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com