Device for passively slowing relative rotation of ultra-large floating body

A relatively rotating and passive technology, applied in the direction of floating buildings, etc., can solve the problems affecting the continuity of the deck, the integrity of the airstrip, etc., and achieve the effect of simple structure, convenient use, convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described below.

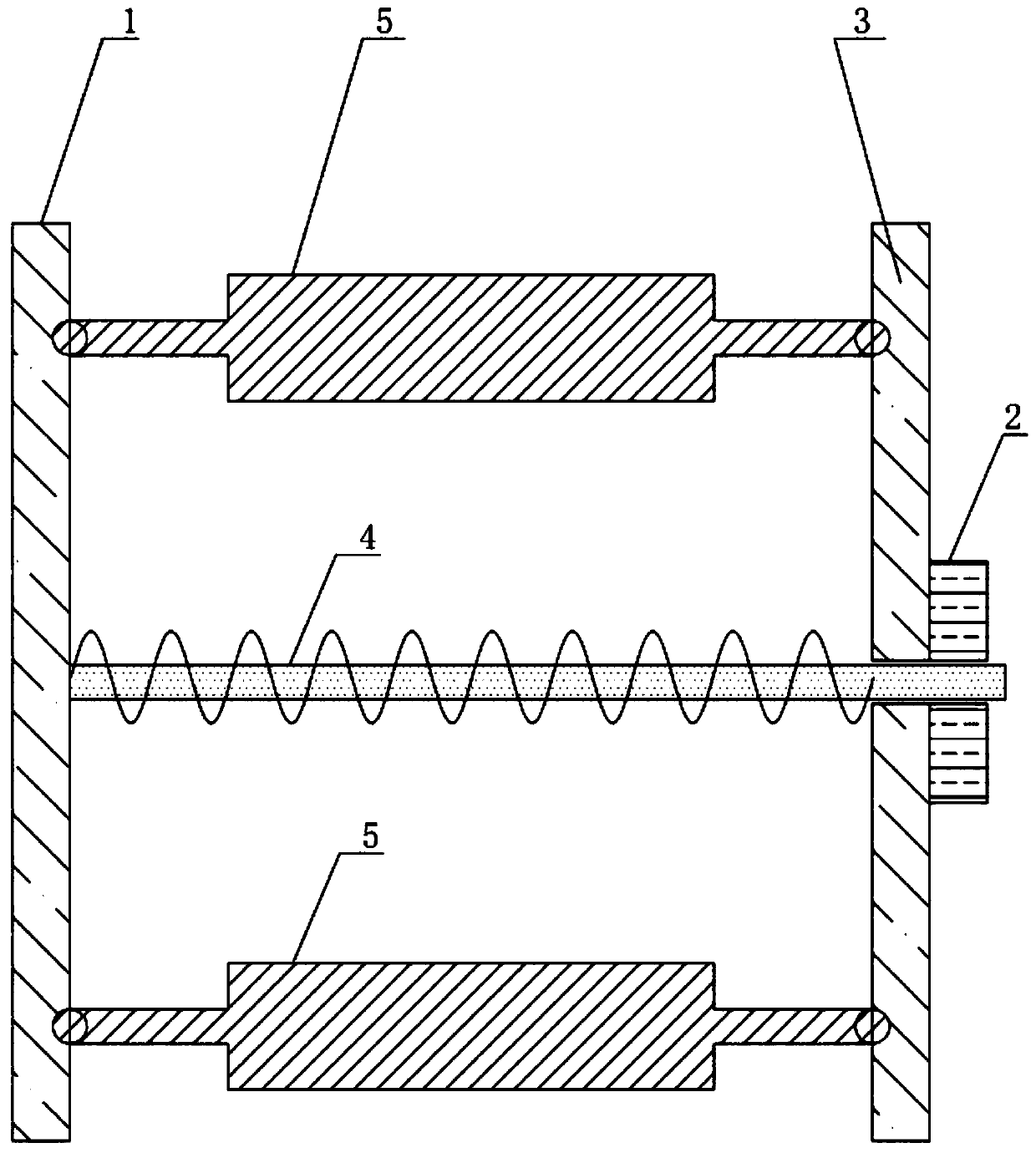

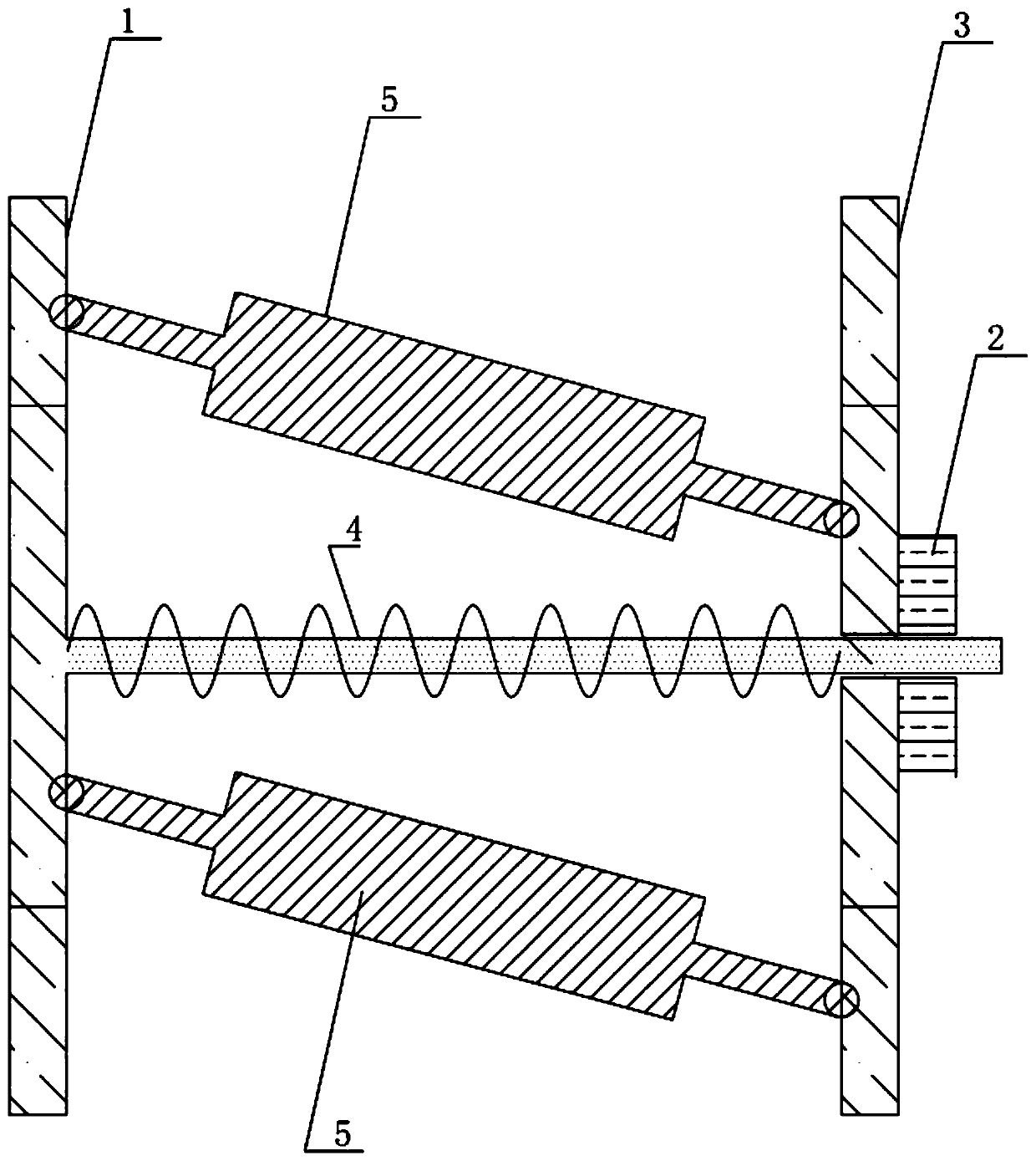

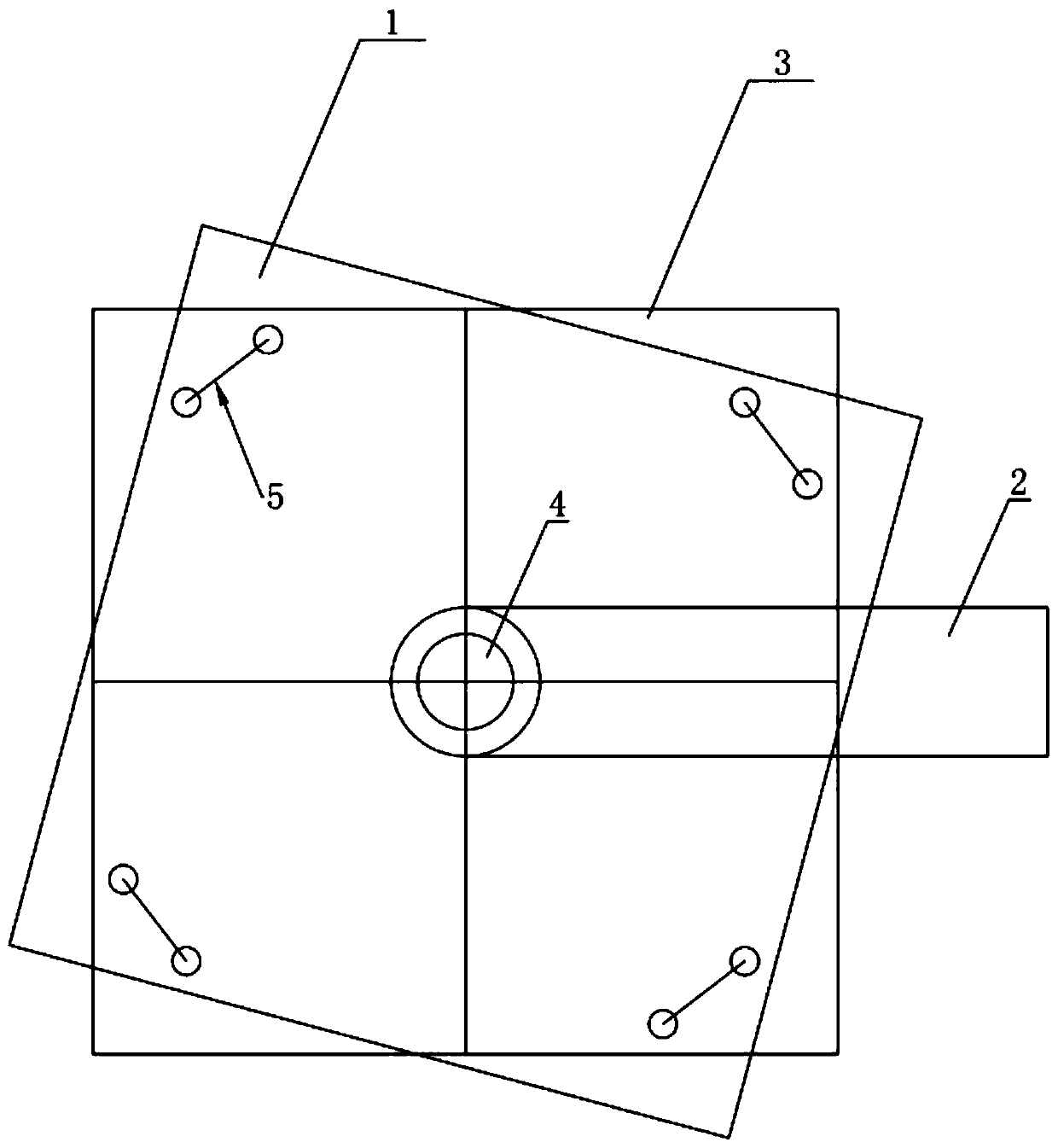

[0022] Such as figure 1 As shown, a device for passively slowing relative rotation of a super-large floating body includes a main base 1 arranged at intervals and a sub-base 3 with holes. Both the main base 1 and the sub-base 3 are made of high-strength steel. The outer end of seat 1 is connected with the upper platform of the ultra-large floating body module. The above-mentioned hole is opened at the center of the sub-base 3, and the outside of the sub-base 3 abuts against the slide bar 2, and one end of the slide bar 2 is fixedly connected to a flange, and the flange opening of the flange plate is connected to the side of the sub-base 3. The holes are concentric. The other end of the above-mentioned slide bar 2 is connected with the outer notch of the upper platform of the super-large floating body module, and it has a one-way sliding function. One end of the guide rod 4 is welded to the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com