A kind of silent anti-vibration composite floor and its preparation method

A composite floor and mute technology, applied in flat products, other household appliances, applications, etc., can solve the problems that have not yet formed industrialized products, and achieve the effects of good elasticity, noise reduction, and sound radiation suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

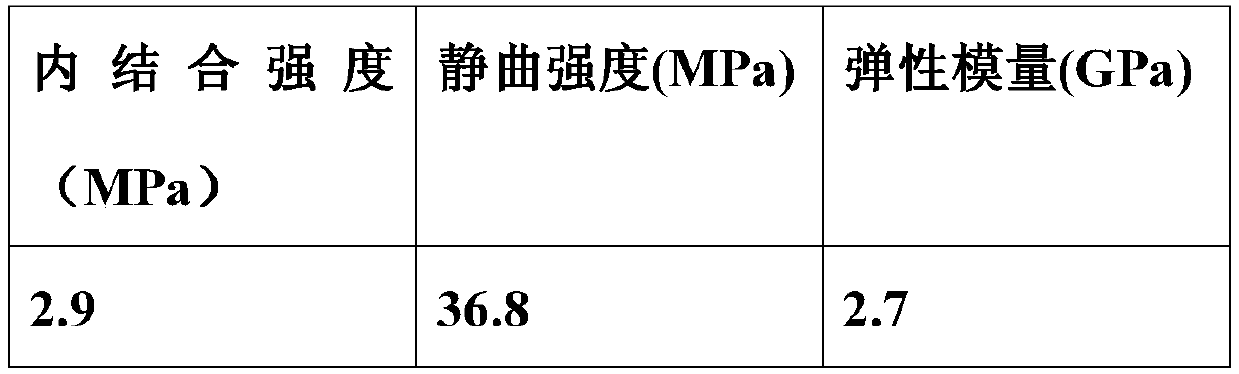

Embodiment 1

[0035] like figure 1 As shown, the silent and anti-vibration composite floor: it includes an outer frame 1 made of solid wood strips, and a composite material 2 is wrapped in the outer frame 1 .

[0036] The composite material is made of the following raw materials in parts by weight: 65 parts of epoxy resin, 20 parts of silica airgel, 60 parts of wood shavings, 60 parts of rubber particles, 20 parts of hydroxypropyl methylcellulose, aliphatic shrink 10 parts of glycerin ether, 1 part of fatty acid amide, 1 part of acrylate, 1 part of hydrogenated nettle oil, 1 part of polyamide, 40 parts of cyclohexanone, and the rubber particles are waste tire rubber particles.

[0037] There are two kinds of wood shavings, one is the shavings after the broken veneer is broken again. Tree species: Poplar; Dry density: 0.40.5g / cm; Moisture content: 9%-10%; Length: 5.030.0mm: Width: 1.53.0mm: Thickness: 0.51.0mm.

[0038] The other is the waste generated during the processing of rotary cutte...

Embodiment 2

[0044] Other is identical with embodiment 1, and difference is:

[0045] The composite material is made of the following raw materials in parts by weight; 40 parts of epoxy resin, 10 parts of silica airgel, 30 parts of wood shavings, 20 parts of rubber particles, 10 parts of hydroxypropyl methylcellulose, aliphatic shrink 3 parts of glycerin ether, 0.2 part of fatty acid amide, 0.2 part of acrylate, 0.2 part of hydrogenated nettle oil, 0.2 part of polyamide, 20 parts of cyclohexanone, and the rubber particles are waste tire rubber particles.

Embodiment 3

[0047] Other is identical with embodiment 1, and difference is:

[0048] The composite material is made of the following raw materials in parts by weight;

[0049] 50 parts of epoxy resin, 12 parts of silica airgel, 40 parts of wood shavings, 30 parts of rubber particles, 12 parts of hydroxypropyl methylcellulose, 5 parts of aliphatic glycidyl ether, 0.5 parts of fatty acid amide, acrylate 0.5 parts, hydrogenated ester nettle oil 0.5 parts, polyamide 0.5 parts, cyclohexanone 25 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com