Coal seam gas fracturing and mash gas driving method

A gas driving and gas fracturing technology, applied in the field of gas fracturing, can solve the problems of blocking gas migration channels and unfavorable gas drainage, and achieve the effects of reducing gas gushing, improving gas permeability, and avoiding gas exceeding the limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

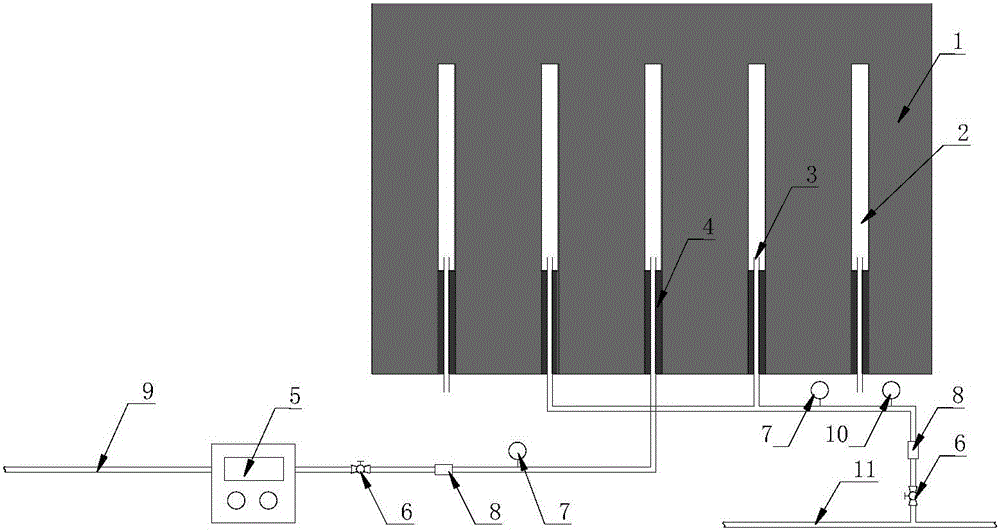

Image

Examples

Embodiment 1

[0020] Embodiment 1: The method for coal seam gas fracturing and gas driving of the present invention includes two stages of sealing and fracturing and gas driving. For example, the average thickness of a coal seam in a certain mine is about 2.51m, and the buried depth is about 800m. The coal seam is stable. The structure is simple, and the inclination angle of the coal seam is about 0°~6°, with an average of 4°. It occurs in the middle and lower part of the Shanxi Formation, about 50m away from the limestone at the top of the Carboniferous Taiyuan Formation, 36.6m away from the sandstone at the bottom of the coal seam, and about 50m away from the K 4 The aluminum mudstone is 51.51m, the roof is sandy mudstone or sandstone, the floor is sandy mudstone and siltstone, and the coal seam is relatively stable. The gas content is about 11.15m 3 / t, gas drainage radius is 5m, coal seam permeability coefficient is 0.0861m 3 / (MPa 2 .d). The damage type of the coal seam belongs to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com