High-strength ultrathin heavy-packaged thermal contraction film and preparation method thereof

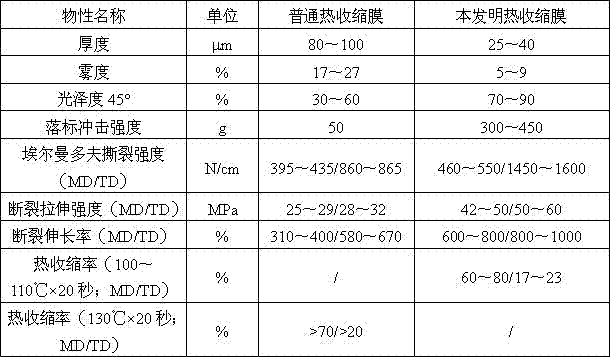

A heat-shrinkable film and heavy packaging technology, which is applied in the fields of new polymer functional film materials, polymer materials, and packaging films, can solve problems such as limiting the use range of heat-shrinkable films, dissolution and degradation pollution, and increased production costs. Material, light weight, easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] This example is the preparation of high-strength ultra-thin heavy packaging heat-shrinkable film. The specific process is: the outer layer is made of mixed raw materials: high-density polyethylene: metallocene polyethylene (1): linear low-density polyethylene: hydroxyl-modified ternary vinyl chloride resin: non-crystalline copolyester mass ratio 1: 4: 10: 1: 1; the mixed raw materials used for the middle layer are: linear low-density polyethylene: high-density polyethylene: metallocene polyethylene (2): hydroxy-modified ternary vinyl chloride resin: non-crystalline The mass ratio of permanent copolyester is 5: 2: 2: 1: 1; the inner layer is made of high-density polyethylene: linear low-density polyethylene: metallocene polyethylene (1): non-crystalline copolymer The mass ratio of esters is 3:1:1:1.

[0019] The metallocene polyethylene (1) has a melt index of 0.3g / 10min and a density of 0.927g / cm 3 metallocene polyethylene; the metallocene polyethylene (2) has a melt ...

Embodiment 2

[0024] This example is the preparation of high-strength ultra-thin heavy packaging heat-shrinkable film. The specific process is: the outer layer is made of mixed raw materials: high-density polyethylene: metallocene polyethylene (1): linear low-density polyethylene: hydroxyl-modified ternary vinyl chloride resin: non-crystalline copolyester mass ratio 1.5︰12︰20︰1︰1; the mixed raw materials used for the middle layer are: linear low-density polyethylene: high-density polyethylene: metallocene polyethylene (2): hydroxy-modified ternary vinyl chloride resin: non-crystalline The mass ratio of permanent copolyester is 8: 3: 3: 1: 1; the mixed raw materials used for the inner layer are: high density polyethylene: linear low density polyethylene: metallocene polyethylene (1): amorphous copolyethylene The mass ratio of polyester is 4:1.5:1:1.

[0025] The metallocene polyethylene (1) has a melt index of 0.5g / 10min and a density of 0.944g / cm 3 metallocene polyethylene; the metallocen...

Embodiment 3

[0030] This example is the preparation of high-strength ultra-thin heavy packaging heat-shrinkable film. The specific process is: the outer layer is made of mixed raw materials: high-density polyethylene: metallocene polyethylene (1): linear low-density polyethylene: hydroxyl-modified ternary vinyl chloride resin: non-crystalline copolyester mass ratio 1~1.2︰5︰15︰1︰1; the mixed raw materials used for the middle layer are: linear low-density polyethylene: high-density polyethylene: metallocene polyethylene (2): hydroxy-modified ternary vinyl chloride resin: The mass ratio of non-crystalline copolyester is 6:2.5:2.5:1:1; the mixed raw material used for the inner layer is: high-density polyethylene: linear low-density polyethylene: metallocene polyethylene (1): amorphous The mass ratio of the permanent copolyester is 3.5:1.2:1:1.

[0031] The metallocene polyethylene (1) has a melt index of 0.4 g / 10 min and a density of 0.935 g / cm 3 metallocene polyethylene; the metallocene pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com