Polyurethane resin for shoes

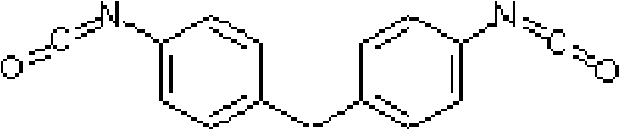

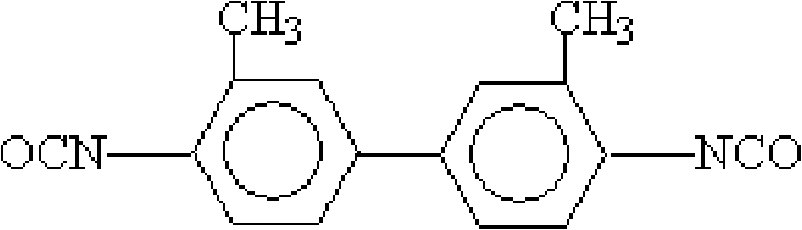

A technology for polyurethane shoes and resin is applied in the field of low-density and high-foaming polyurethane shoe resin, and can solve the problems of high defect rate, white turbidity, unstable storage of liquefied diphenylmethane diisocyanate and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

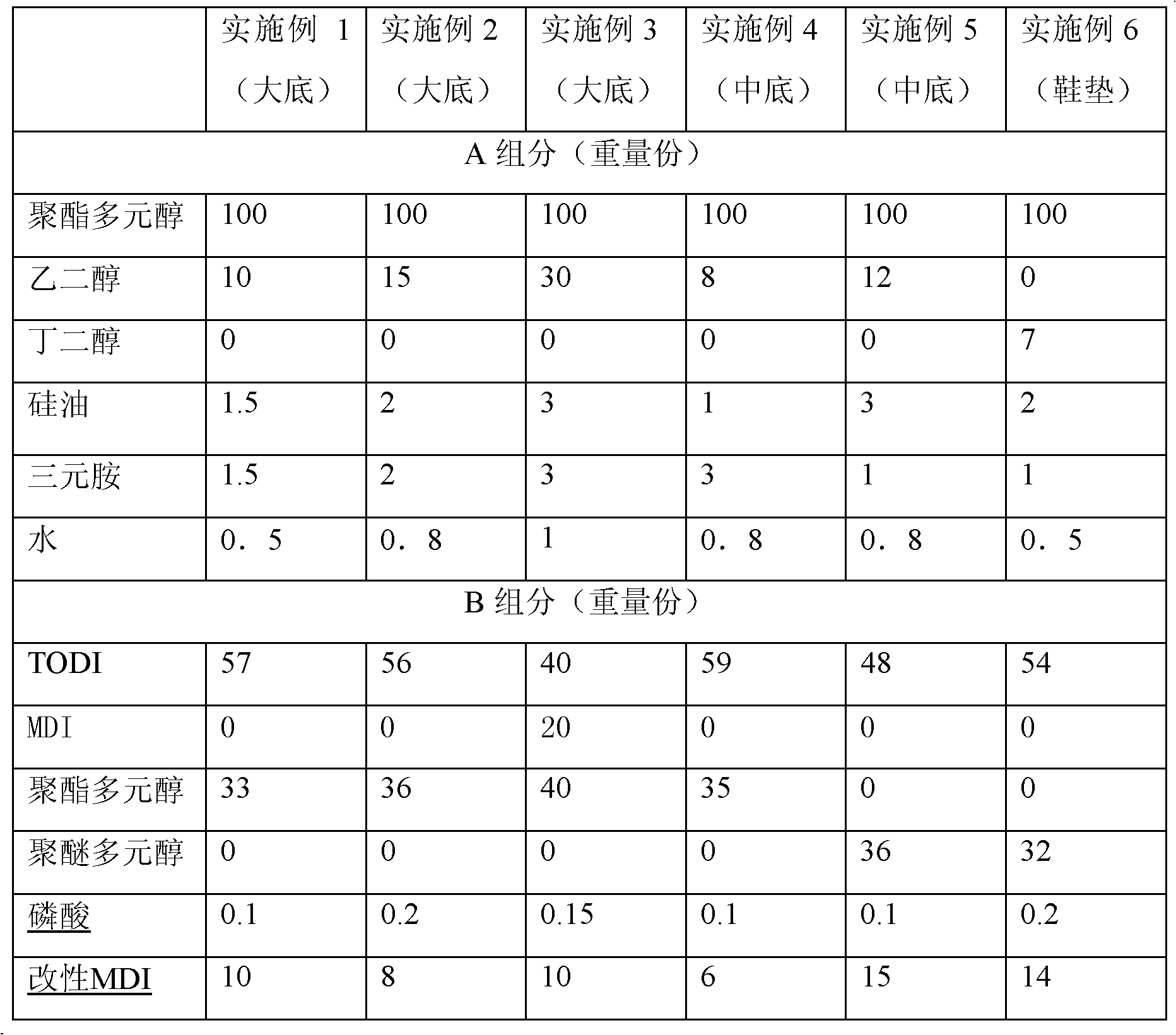

[0027] Preparation of component A: Mix and stir polyester polyol, ethylene glycol, silicone oil, triamine and water at a temperature of 50-60°C for 10-15 hours to prepare component A.

[0028] Preparation of component B: Mix and stir TODI, polyester polyol, phosphoric acid and modified MDI at a temperature of 50-70° C. for 6-8 hours to prepare component B.

[0029] Component B and component A are foamed on a polyurethane foaming machine at a weight ratio of 1:0.7, injected into a mold, and demolded to obtain a shoe outsole.

[0030] The parameters of the shoe outsole product prepared according to the formula of this embodiment and the product prepared according to the existing formula are compared in the following table. (In the formula of polyurethane shoe resin, the isocyanates of component B are 3.3'-dimethyl-4.4'biphenyl diisocyanate (TODI) and diphenylmethane diisocyanate (MDI), and the rest of the components and their contents are same.)

[0031]

[0032] ...

Embodiment 2

[0035] The preparation of component A and component B and the method of foam injection molding are the same as in Example 1.

[0036] The weight ratio of component B to component A is 1:0.8.

[0037] The parameters of the shoe outsole product prepared according to the formula of this embodiment and the product prepared according to the existing formula are compared in the following table. (In the formula of polyurethane shoe resin, the isocyanates of component B are 3.3'-dimethyl-4.4'biphenyl diisocyanate (TODI) and diphenylmethane diisocyanate (MDI), and the rest of the components and their contents are same.)

[0038]

[0039] This embodiment replaces the MDI in the prior art with TODI, under the situation of equal density, the physical properties such as wear resistance, bending resistance, tensile strength, tear strength of the outsole of shoes all strengthen to some extent, prepolymer is relatively Stable, relatively mild during foaming reaction, not easy to p...

Embodiment 3

[0041] Preparation of component A: Mix and stir polyester polyol, ethylene glycol, silicone oil, triamine and water at a temperature of 50-60°C for 10-15 hours to prepare component A.

[0042] Preparation of component B: Mix and stir TODI, MDI, polyester polyol, phosphoric acid and modified MDI at a temperature of 50-70° C. for 6-8 hours to prepare component B.

[0043] Component B and component A are foamed on a polyurethane foaming machine at a weight ratio of 1:0.85, injected into a mold, and demoulded to obtain a shoe outsole.

[0044] The parameters of the shoe outsole product prepared according to the formula of this embodiment and the product prepared according to the existing formula are compared in the following table. (In the formula of polyurethane shoe resin, the isocyanates of component B are 3.3'-dimethyl-4.4'biphenyl diisocyanate (TODI) and diphenylmethane diisocyanate (MDI), and the rest of the components and their contents are same.)

[0045]

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com