Decohesion lining and pressure-sensitive adhesive therewith

A technology of pressure-sensitive adhesives and release liners, which is applied to film/sheet adhesives, adhesives, pressure-sensitive films/sheets, etc., and can solve problems such as release liner rupture and reduced work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

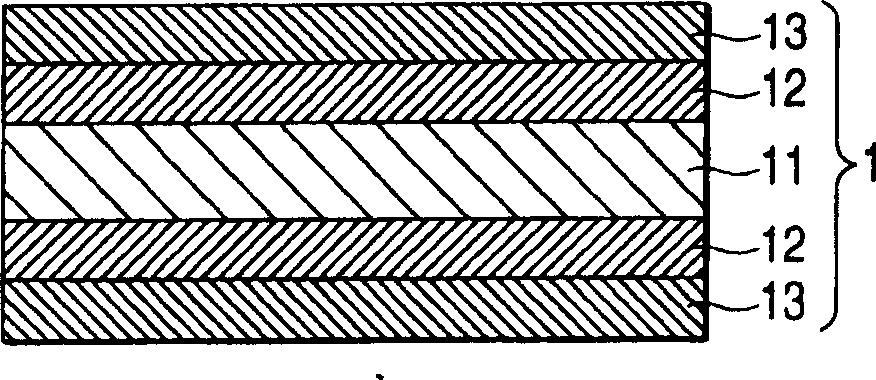

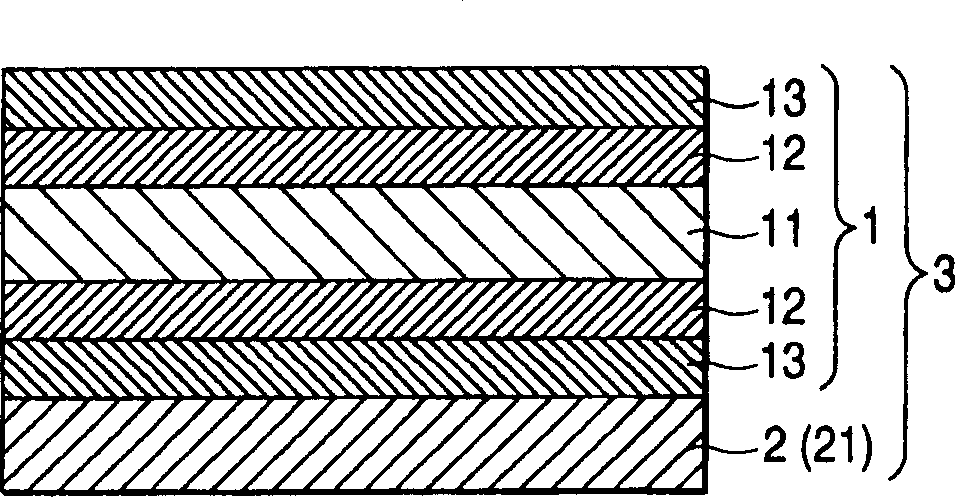

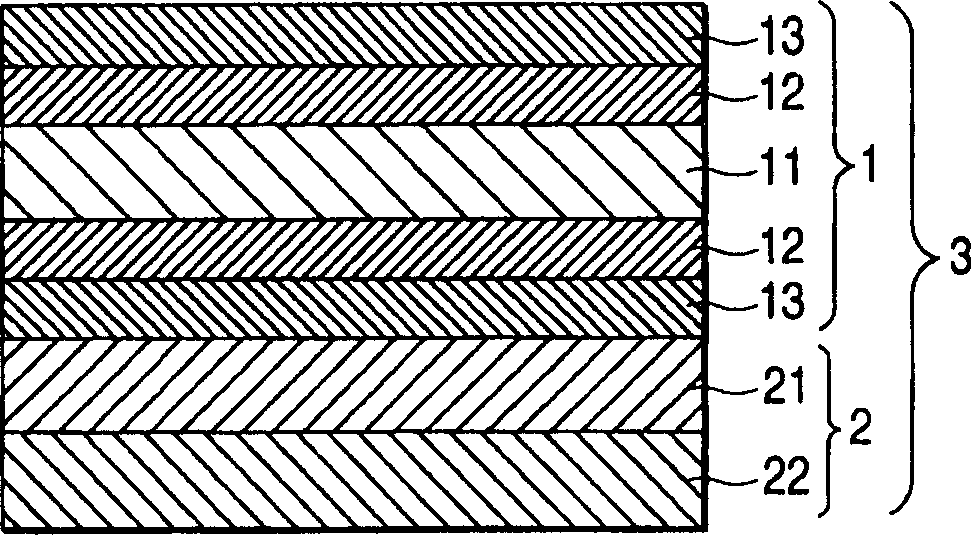

Image

Examples

Embodiment 1

[0041] (Preparation of release liner)

[0042] Silica is fixed to a thickness of 93 μm and a basis weight of 68.0 g / m with an isocyanate adhesive 2 and the density is 0.73g / cm 3 On each side of the wood-free paper, a clay coating (3 μm) was formed. A further silicone layer (0.8 μm) was formed on each side, resulting in a release liner.

[0043] (Preparation of pressure-sensitive adhesive sheet with release liner)

[0044] The release liner was removed from the double-sided adhesive tape (No. 500, manufactured by Nitto Denko Crop.). The release liner prepared above was applied to each side of the exposed adhesive layer to prepare a pressure-sensitive adhesive sheet with a release liner.

Embodiment 2

[0046] Silica was fixed with isocyanate adhesive to a thickness of 86 μm and a basis weight of 68.7 g / m 2 and density of 0.80g / cm 3 On each side of the wood-free paper, a clay coating (3 μm) was formed. A further silicone layer (0.8 μm) was formed on each side, resulting in a release liner.

[0047] (Preparation of pressure-sensitive adhesive sheet with release liner)

[0048] The release liner was removed from the double-sided adhesive tape (No. 500, manufactured by Nitto Denko Crop.). The release liner prepared above was applied to each side of the exposed adhesive layer to prepare a pressure-sensitive adhesive sheet with a release liner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com