Corrosion resistant metallurgical powder compositions, methods, and compacted articles

a technology of corrosion resistance and metallurgical powder, which is applied in the field of corrosion resistant metallurgical powder compositions and compacted articles, can solve the problems of insufficient improvement, inability to achieve high strength applications of some stainless steels, and increase the cost of preparing compacted articles. achieve high fatigue endurance limits, maintain ductility, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

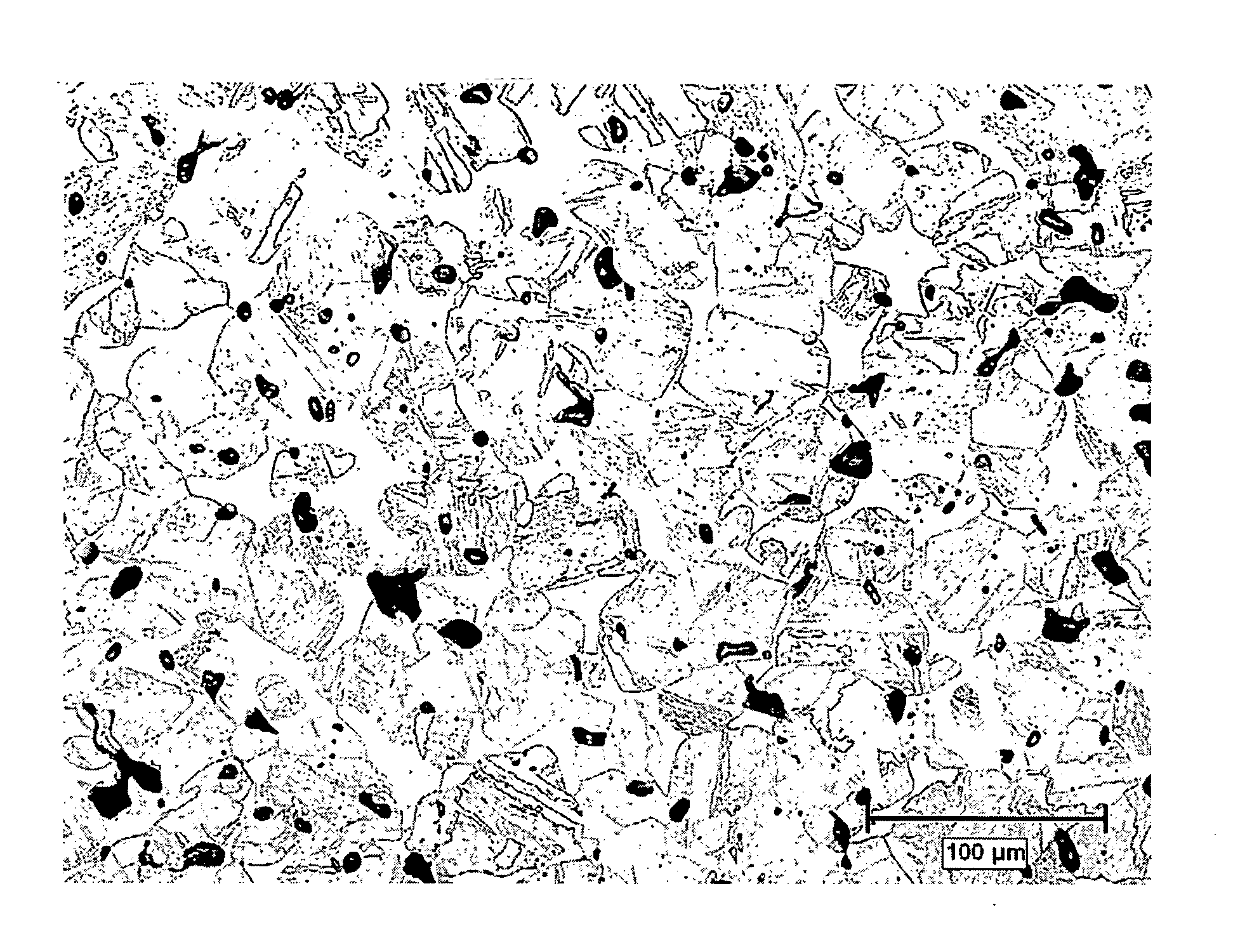

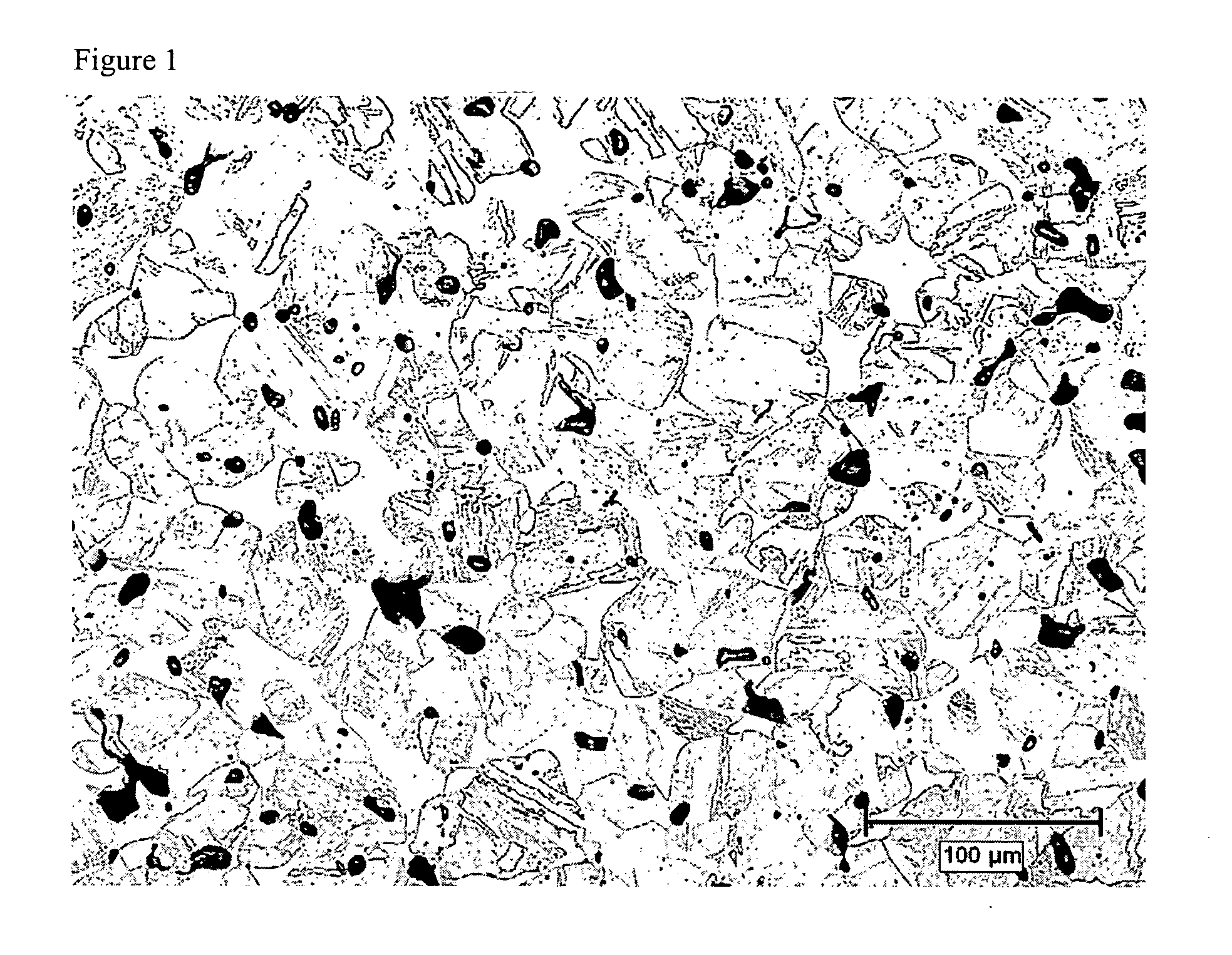

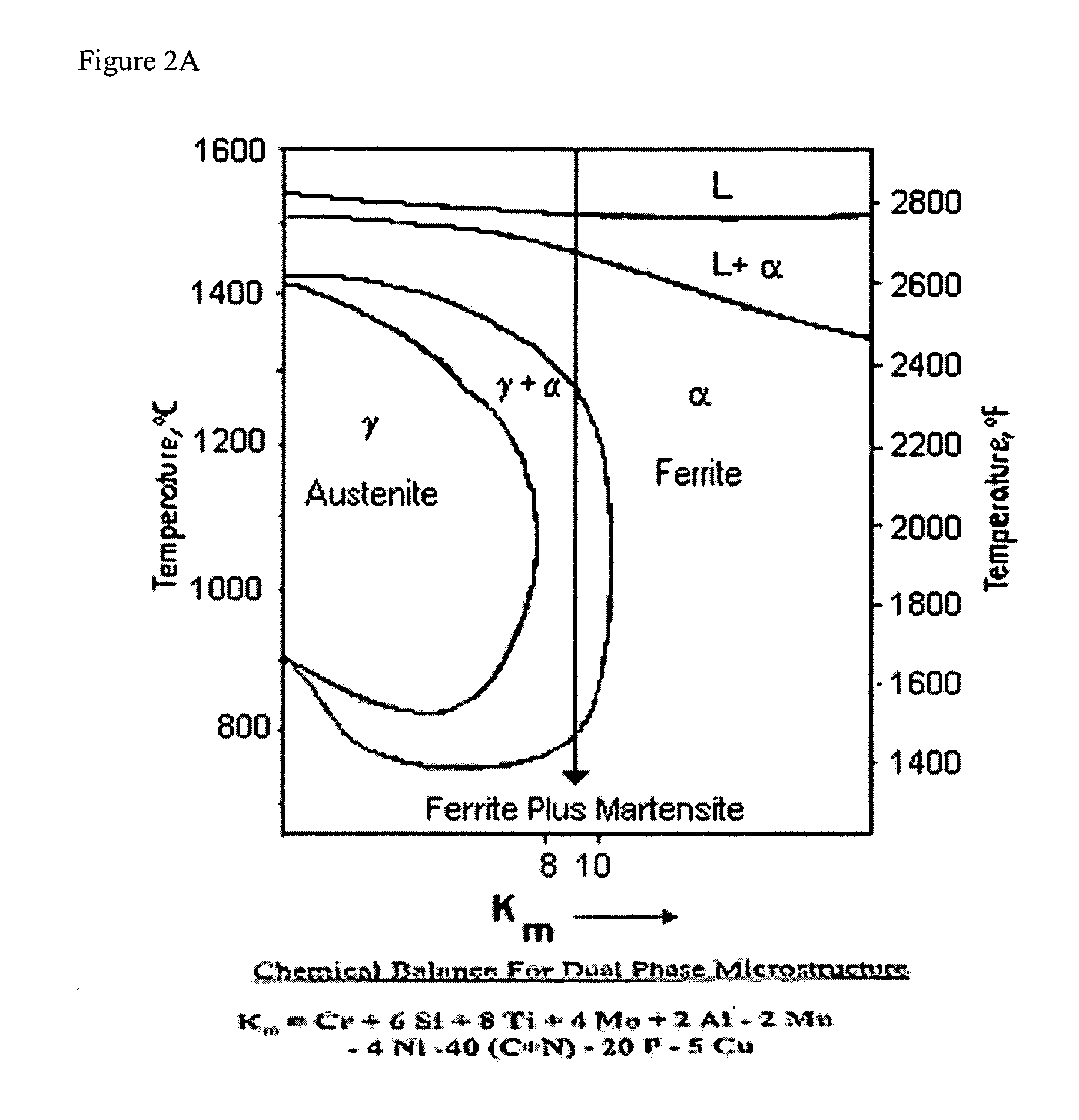

[0095] Corrosion resistant metallurgical powder compositions, identified as test compositions DP1 through DP5, were prepared and compared with commercially available stainless steel compositions. Test compositions DP1 through DP 5 were prealloyed iron based powders that included the alloying alements shown below in Table 1. The iron and alloy elements of each composition were melt blended and water atomized to provide corrosion resistant metallurgical powder compositions. The atomized powders were than admixed with 0.75 weight percent of lubricant, which was commercially available as Acrawax C, from Lonza Corporation. DP1 though DP5 had ferritic factors ranging from 6.1 to 14.2. These test compositions were compared to two conventional ferritic stainless steel powders, commercially available as 410L and 430L grade powders from Hoeganaes Corporation. The 410L powder was admixed with graphite powder prior to compaction and sintering to provide a higher martensitic microstructure.

TAB...

example 2

[0103] The mechanical and physical properties of corrosion resistant compacts were compared to conventional stainless steels typically used in high strength applications. A compacted article, DP6, was prepared according to the steps described above with the composition shown in Table 4 below. The conventional stainless steels tested were commercially available as 17-4PH, 409LNi, and 410L with graphite addition, each sold by Hoeganaes Corporation. The 17-4PH powder was a precipitation hardening, martensitic stainless steel that combines high strength and hardness with corrosion resistance. Upon compaction, articles prepared from this powder were age hardened prior to testing. The 409LNi powder is an admixture of conventional 409Cb powder commercially available from Hoeganaes Corporation and elemental nickel powder commercially available from Inco-123. 409Cb is typically used in conventional automotive exhaust flange applications. As described above, the 410L+graphite compositions, ha...

example 3

[0111] The corrosion resistance properties of the compacted parts from Example 2 were tested. Two types of corrosion tests were performed. The first corrosion test, a salt spray test, was performed on the compacts according to ASTM Standard B 117-03. Five test bars were tested per alloy. The percent area of the bars covered by red rust was recorded over time. The results are shown below in Table 8:

TABLE 8Red Rust After 24 Hours(%)DP65.00410L + graphite84.00409LNi20.0017-4PH1.0

[0112] As shown in Table 8, the high alloy content of the compact prepared from 17-4PH result in the lowest amount of rust after 24 hours, i.e., the highest resistance to corrosion. However, at lower chromium levels the compacts prepared with DP6 exhibited comparable resistance to corrosion. The corrosion resistance of the compact prepared from DP6 was superior to the corrosion resistance of the compacts prepared from 409LNi and 17-4PH respectively. Without being limited by theory it is believed that the addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com