Multilayered knitted fabric

A technology for knitting grey fabrics and grey fabrics, applied in knitting, weft knitting, warp knitting and other directions, can solve the problems of insufficient dryness and stickiness of the skin, and achieve the effects of excellent abrasion resistance and good hand feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

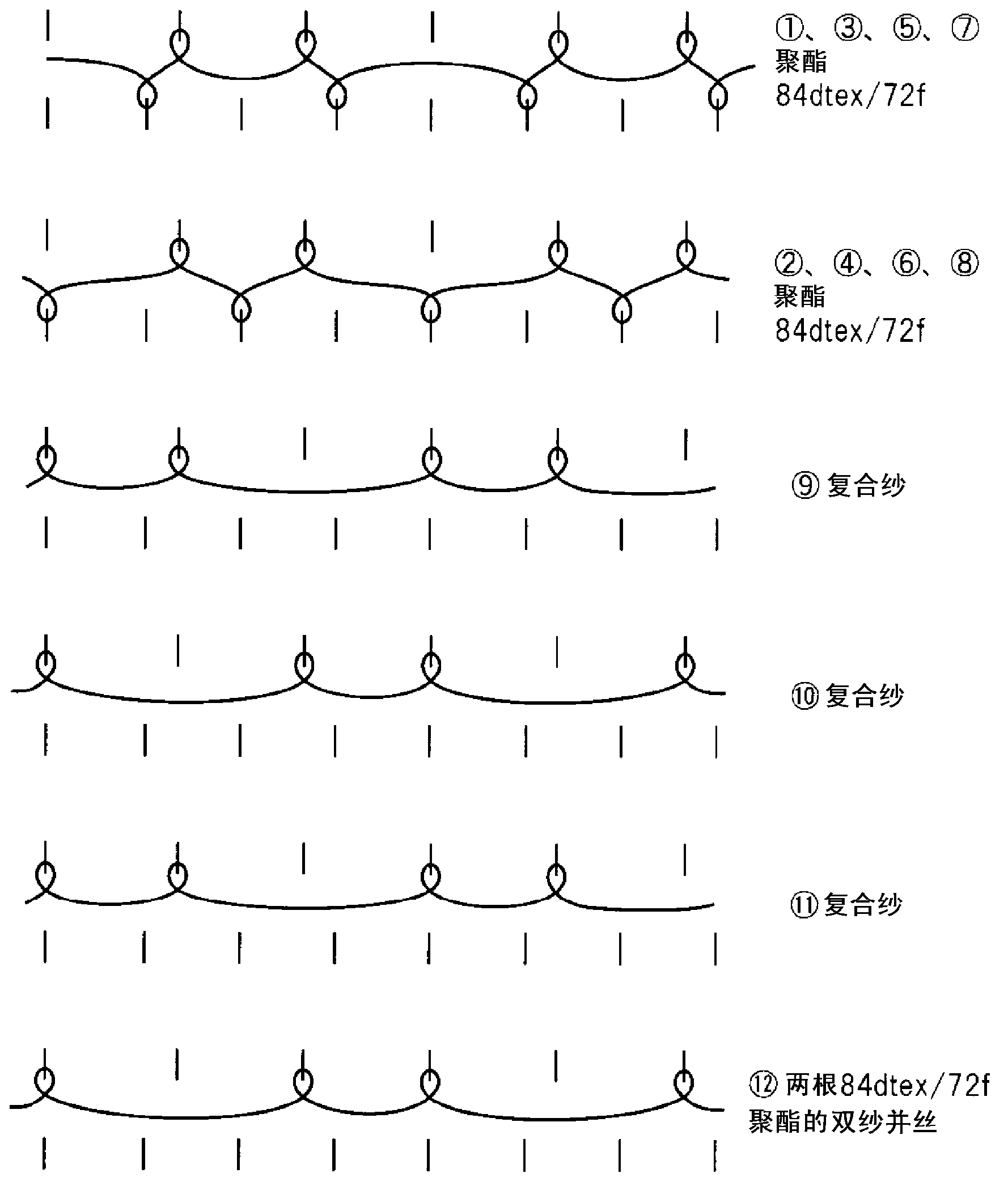

[0110] Use a double-sided circular weft machine of different machine numbers with 18GG on the dial side and 24GG on the cylinder side, according to figure 1 The knitting structure shown (circled numbers in the figure indicate the order of the loops), the composite yarn (crimp elongation 7.4%) and the yarn obtained by doubling 4 pieces of 84dtex / 72f polyester round-section processed yarn (total fineness 336dtex), so as to obtain knitted gray fabric, the composite yarn is 84dtex / 72f polyester round section processed yarn, 33dtex / 24f cupro round section yarn and 56dtex / 72f polyester round section yarn intertwined and blended Made after false twisting. The knitted gray fabric was scoured and washed in a flow dyeing machine at 80°C for 20 minutes, and then pre-set at 180°C for 90 seconds at a tenter rate of 20% in a pin tenter. Thereafter, dyeing of polyester at 130°C in a liquid flow dyeing machine, water absorption processing, and water washing were carried out, and then stretc...

Embodiment 2

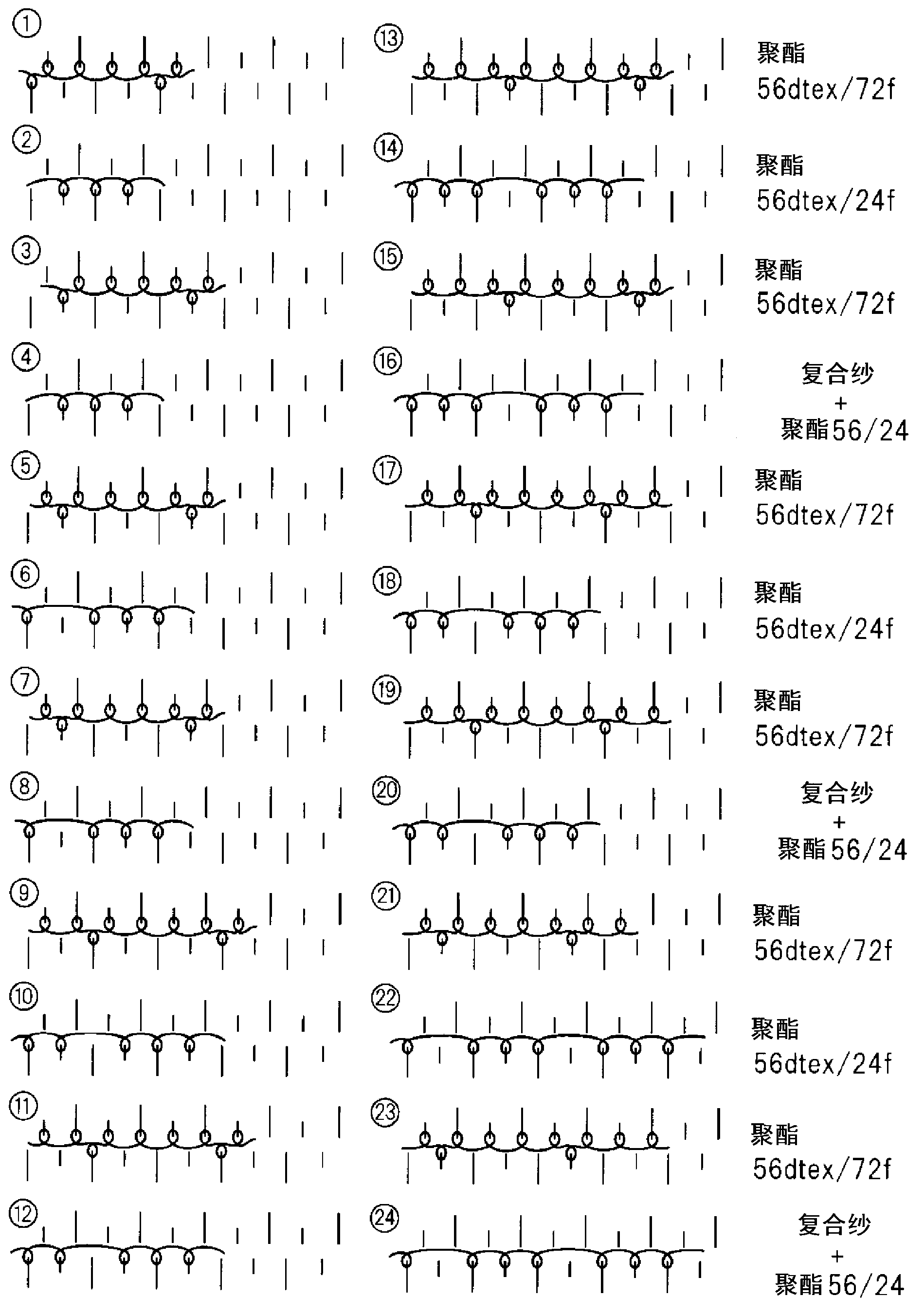

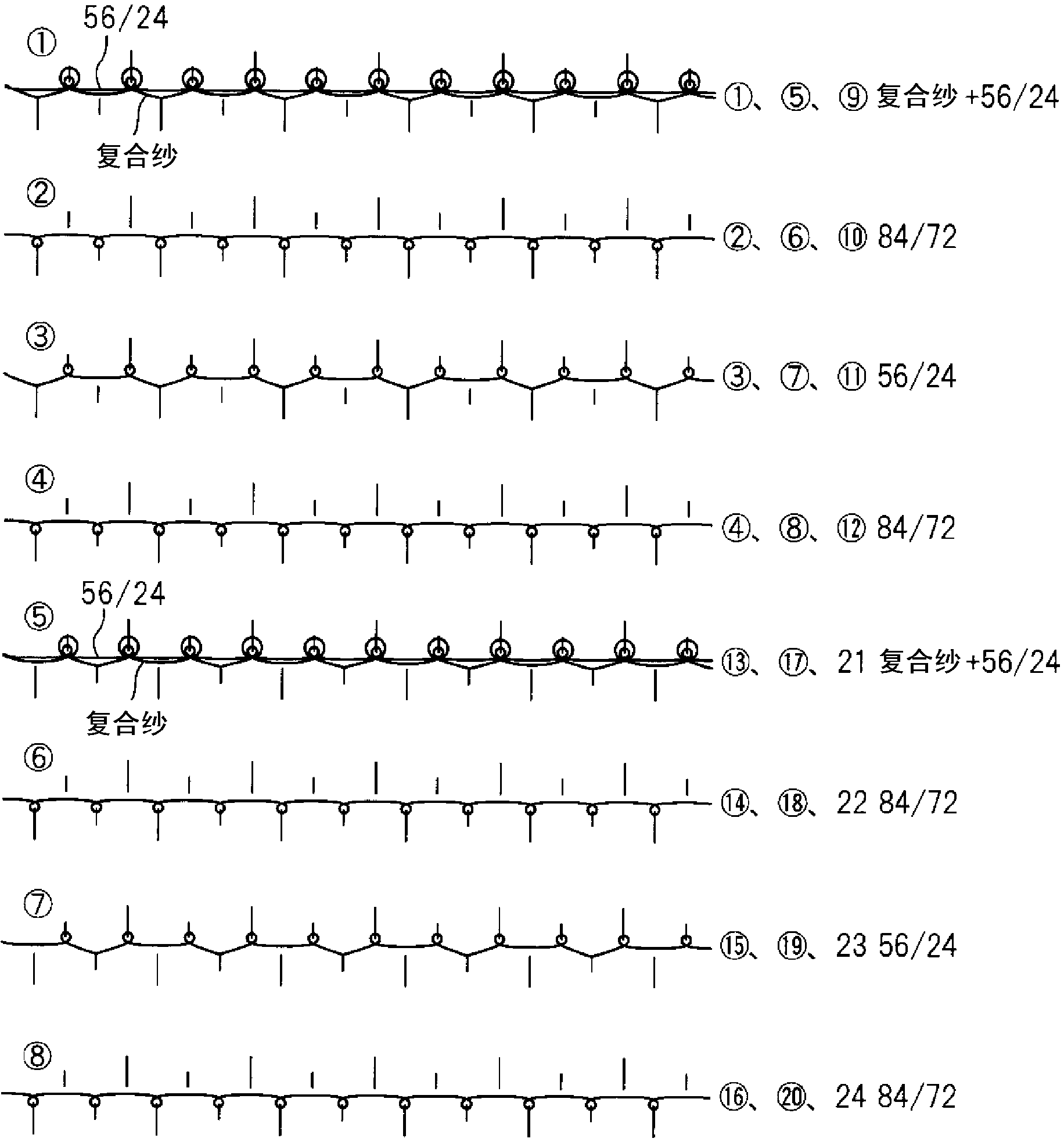

[0112] Use 28-gauge double-sided circular knitting machine, such as figure 2 (circled numbers in the figure show the sequence of knitting, and in the knitting positions recorded in the same line (such as circled numbers 1 and 13), the same yarn type is fed), Feed composite yarn and 56dtex / 24f polyester circular section processed yarn, said composite yarn is the polyester circular section processed yarn of 56dtex / 72f polyester circular section yarn, 33dtex / 24f cuproammonium circular section yarn and 56dtex / 72f It is made by false twisting after intertwining and blending. Plating is performed when feeding composite yarn and 56dtex / 24f polyester circular cross-section processed yarn, and the composite yarn is arranged on the inner side of the knitted gray fabric to form loops, the same as in Example 1. Processing to obtain surface density of 134g / m 2 , Knitted gray fabric with a thickness of 0.69mm. On the surface A side of the obtained knitted gray fabric, there were protrusi...

Embodiment 3

[0114] Using a 28GG tricot machine, arrange a 56dtex / 24f polyester round-section processed yarn in the weave 10 / 23 on the front, and arrange a 56dtex / 24f polyester round-section processed yarn in the middle according to the weave 21 / 10 alternately 56dtex / 30f copper ammonium circular cross-section yarn, and 56dtex / 30f polyester W-shaped cross-section processed yarn according to the weave 10 / 12. Cupro ammonia round section yarn is mainly configured in the middle layer of knitted gray fabric. Carry out processing in the same manner as Example 1, obtain surface density 138g / m 2 , Knitted gray fabric with a thickness of 0.61mm. On the surface A side of the obtained knitted gray fabric, there were irregularities due to the weaving structure, and the area ratio of cellulose-based long fibers in the outermost layer of the surface A was 9.3%, and the cellulose-based long fibers were arranged obliquely. The appearance area ratio of the cellulose-based long fibers on the surface B was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com