Rotary multi-jet batch spinning device

A spinning device and multi-jet technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as clogging, affecting the stability and instability of the electrospinning tap-jet mode, and overcome backflow Phenomenon, overcoming static suppression interference phenomenon, uniform shunt reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

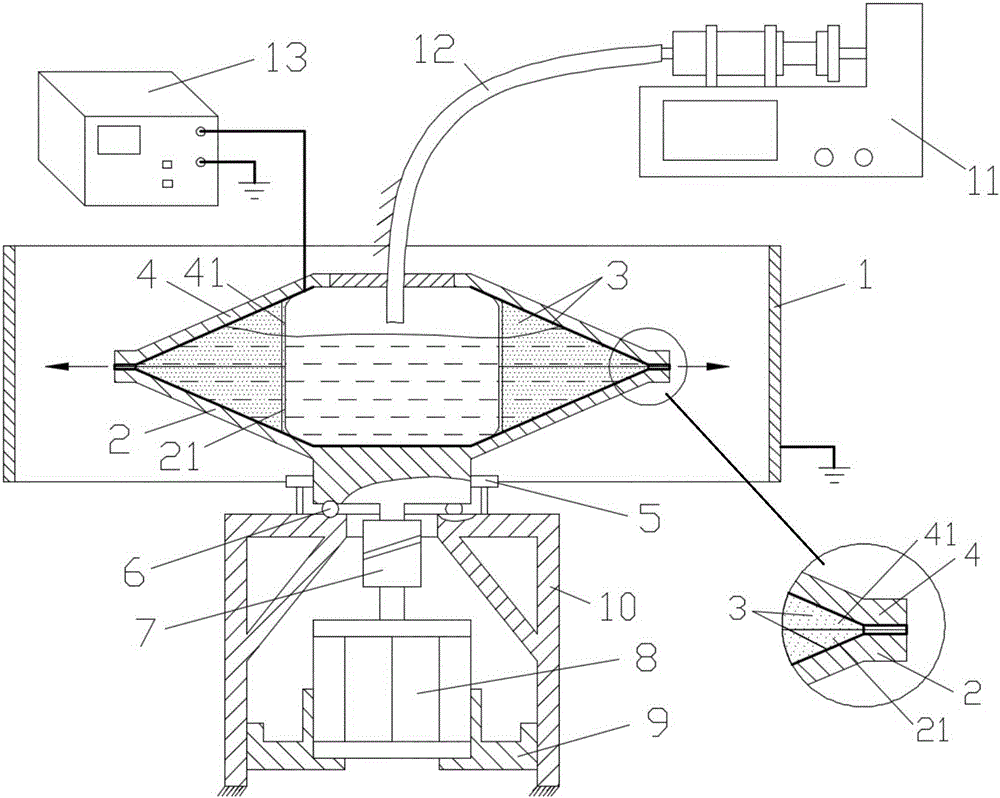

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

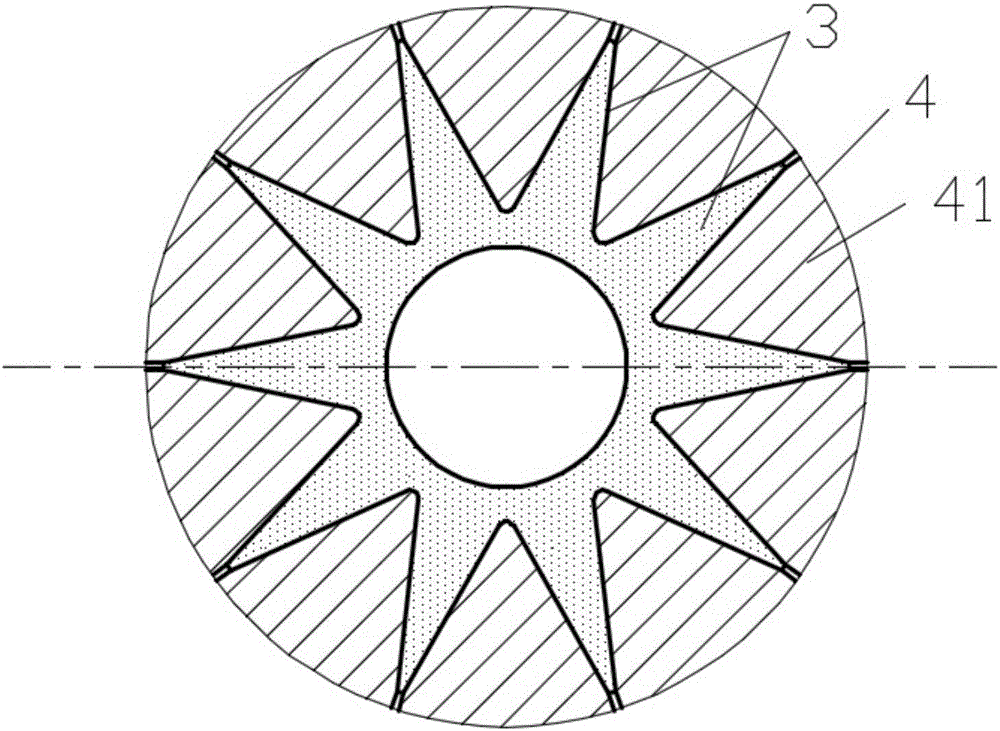

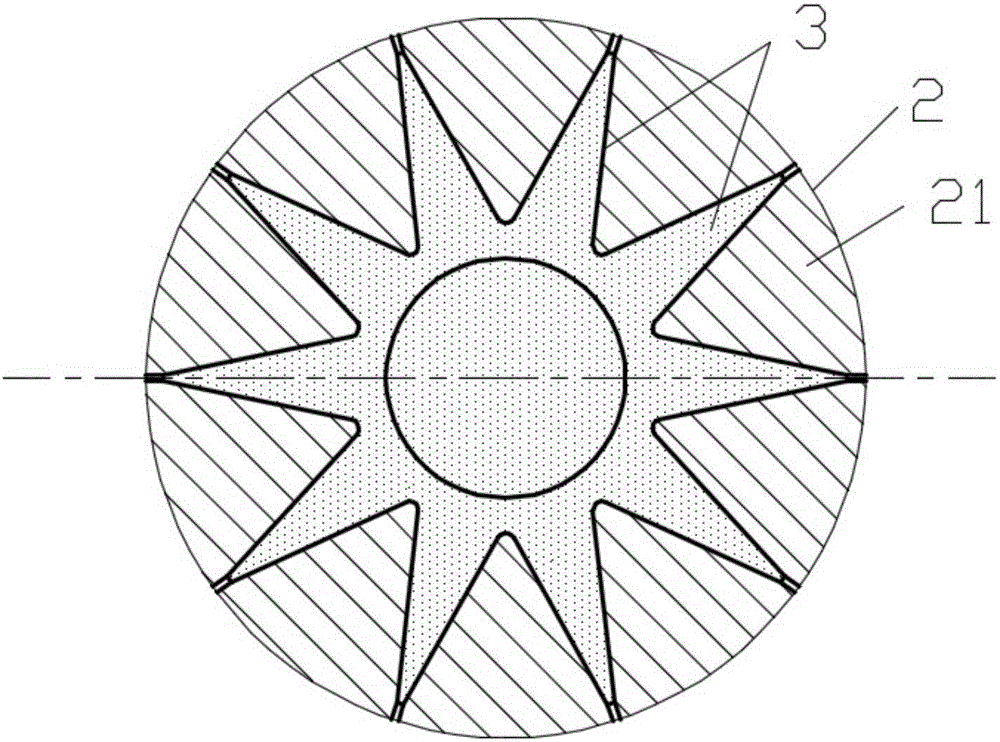

[0020] exist figure 1 Among them, there is an array of upper guide plates 41 on the cover table 4, and an array of lower guide plates 21 on the liquid distributing table 2. The number of arrays of the upper guide plates 41 and the lower guide plates 21 is the same, and the liquid distributing table 2 and the cover table 4 are aligned and matched by the guide plate arrays to form a spinning The main body of the spinning nozzle, its internal cavity is used as a spinning solution buffer chamber, because the upper guide plate 41 and the lower guide plate 21 are aligned and matched to form the internal rib structure of the spinning nozzle, which guides the liquid separation of the solution in the internal cavity of the spinning nozzle; The edges of the liquid distribution table 2 and the cover table 4 are designed with an array of grooves, and each groove is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com