Microchannel Heat Exchanger Facilitating Reduced Refrigerant Charge

A micro-channel heat exchanger and micro-channel technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of reducing heat exchanger capacity, increasing processing difficulty, and uneven flow distribution, etc., to achieve Uniform liquid separation, easy processing, and improved heat transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

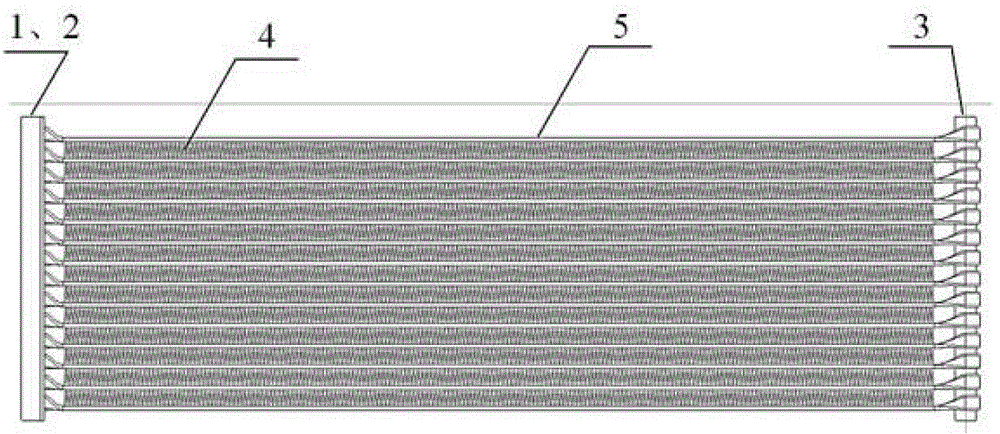

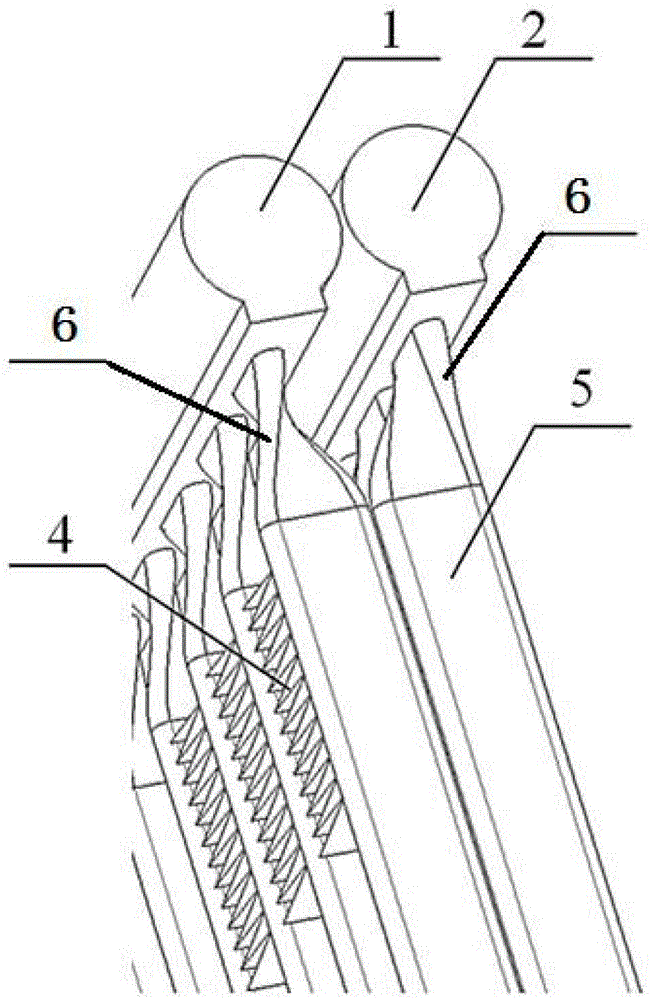

[0026] Such as figure 1 As shown, this embodiment includes: the inlet header 2 and the outlet header 1 on the same side, the fixed pipe 3 on the opposite side, and the two ends are respectively connected to the inlet header 2 and the outlet header 1 and wound around Pass through the microchannel flat tube 5 of the fixed tube 3.

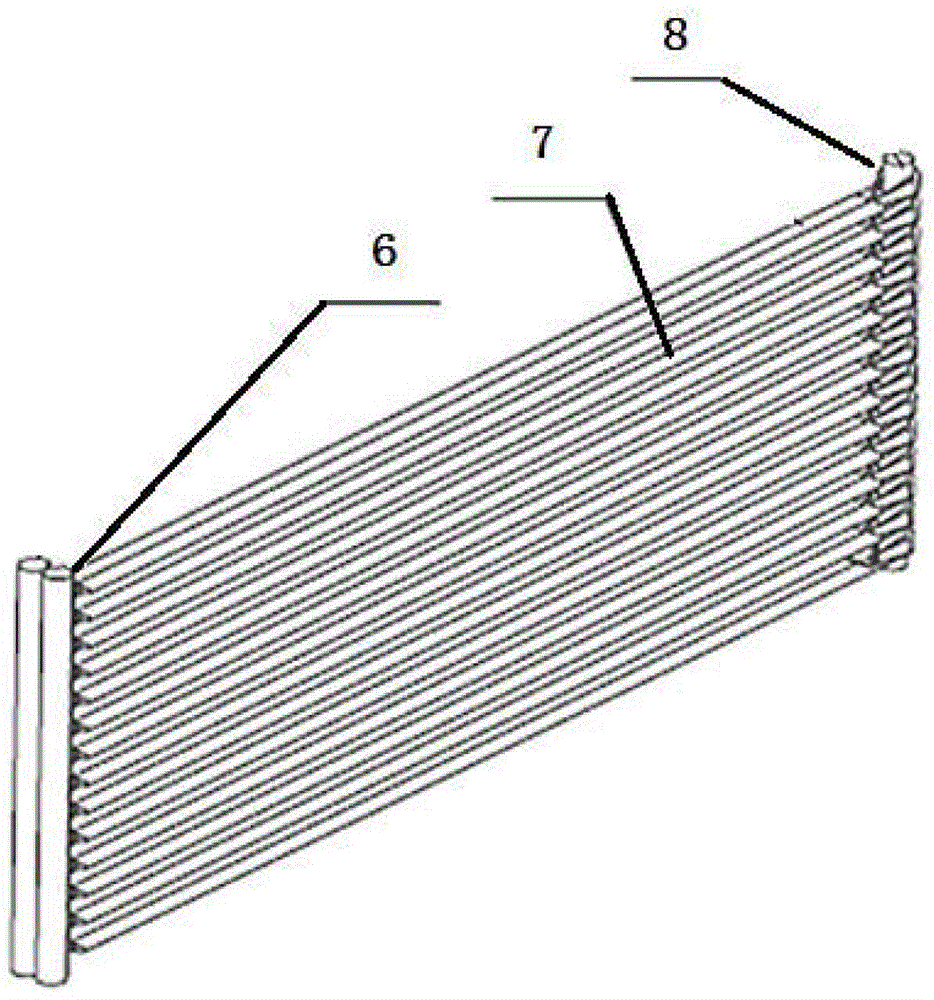

[0027] Such as figure 2 As shown, the microchannel flat tube 5 includes: a connecting part 6, a working part 7 and a transition part 8, wherein: the connecting part 6 is located at both ends of the microchannel flat tube 5 and is connected to the inlet header 2 and the outlet header respectively. The flow tubes 1 are connected, the transition part 8 is located in the middle of the microchannel flat tube 5 and is in contact with the outer surface of the fixed tube 3, the working part 7 is located between the inlet header 2, the outlet header 1 and the fixed tube 3, and the working part 7 is provided with fin 4.

[0028] Such as image 3 As shown, ...

Embodiment 2

[0037] When the inlet header 2 and the outlet header 1 are on both sides, it can be used as Figure 5 The microchannel flat tube mid-stage shown is set up in a finned manner. Then the device only includes inlet header 2 and outlet header 1 located on both sides and microchannel flat tubes 5 connected to inlet header 2 and outlet header 1 respectively.

[0038] The corresponding microchannel flat tube 5 includes: a connecting part and a working part, and fins are arranged on the whole working part.

[0039] The connecting part is a rotating transition structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com