Vapor-liquid separation type liquid separator

A technology of vapor-liquid separation and liquid separator, which is applied in the direction of refrigeration and liquefaction, refrigeration components, refrigerators, etc., can solve the problem of uneven distribution of vapor and liquid, so as to overcome uneven liquid separation, improve heat exchange efficiency, and reduce pressure drop loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

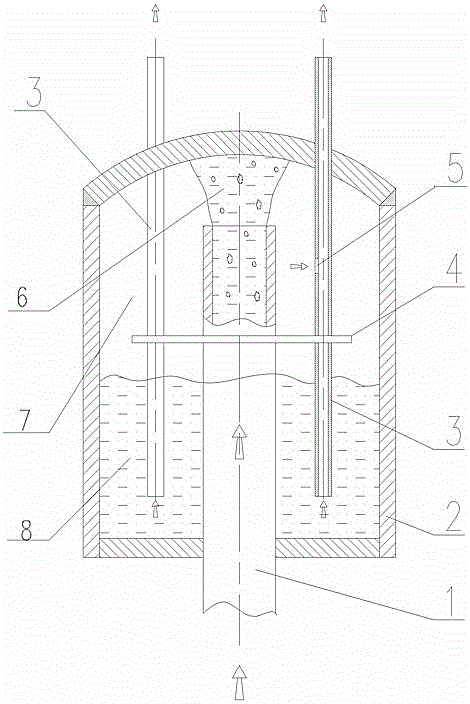

[0008] Such as figure 1 As shown: 2 is the liquid bag, the end of the liquid inlet pipe 1 extends into the upper part of the inner cavity of the liquid bag 2, and there is a fixed orifice plate 4 in the inner chamber of the liquid bag 2, and the fixed orifice plate 4 is fixedly connected to the liquid inlet pipe 1 A plurality of liquid outlet branch pipes 3 are inserted into the holes on the fixed orifice plate 4, each liquid outlet branch pipe 3 is fixedly connected with the fixed orifice plate 4, one end of the liquid outlet branch pipe 3 is located at the lower part of the inner cavity of the liquid bag 2, and the liquid outlet branch pipe 3 is another One end is located outside the liquid bag 2, and each liquid outlet branch pipe 3 is located on the upper part of the inner cavity of the liquid bag 2 to have an air outlet 5.

[0009] The liquid bag 2 has a cylindrical cavity structure. The liquid inlet pipe 1 enters the liquid bag 2 from the center of the bottom of the liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com