Shell and tube heat exchanger

A shell-and-tube heat exchanger and heat exchange tube technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problem of low heat transfer performance of heat transfer surface and achieve uniform liquid separation , Improve the heat transfer coefficient and improve the effect of heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

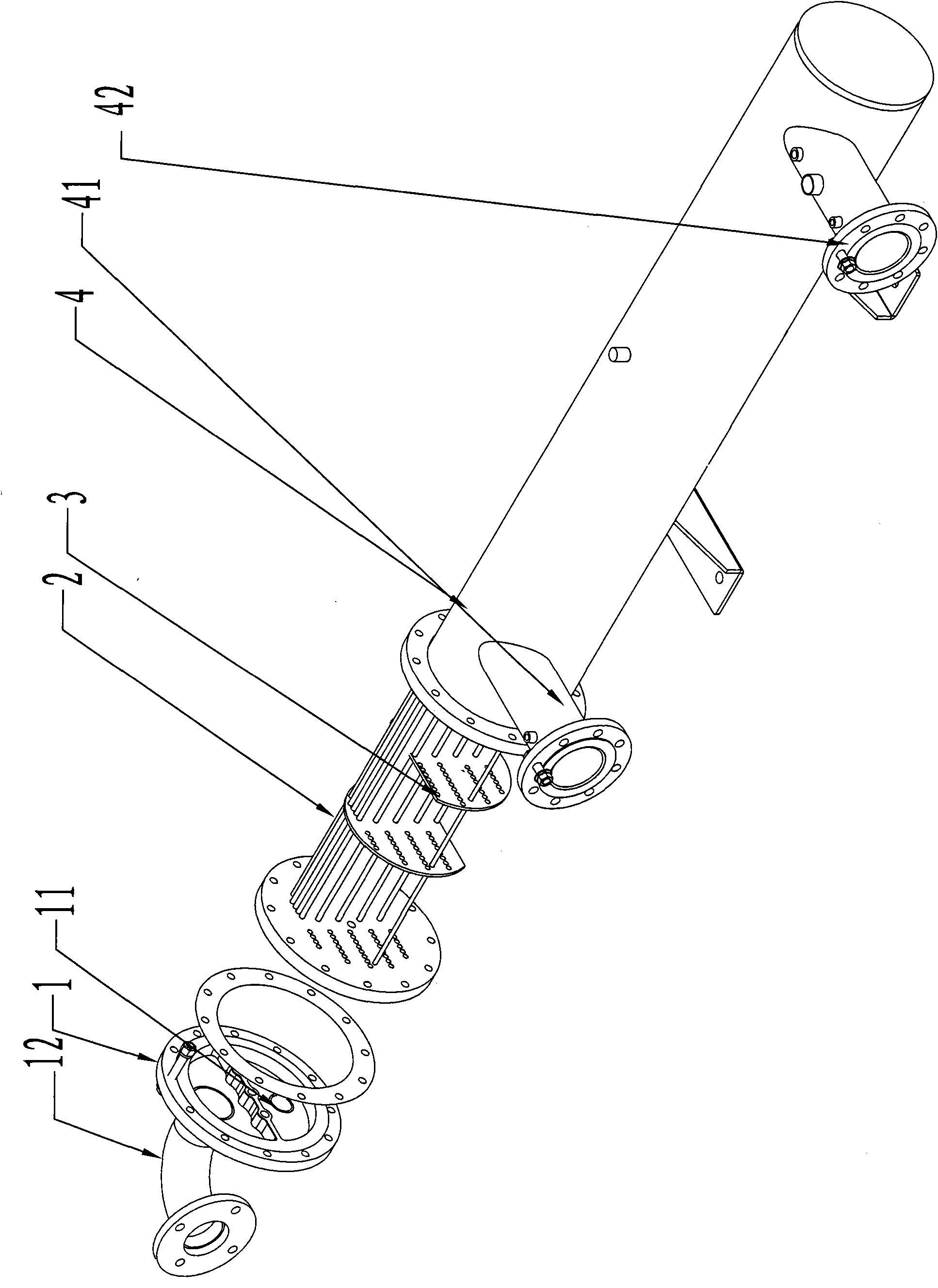

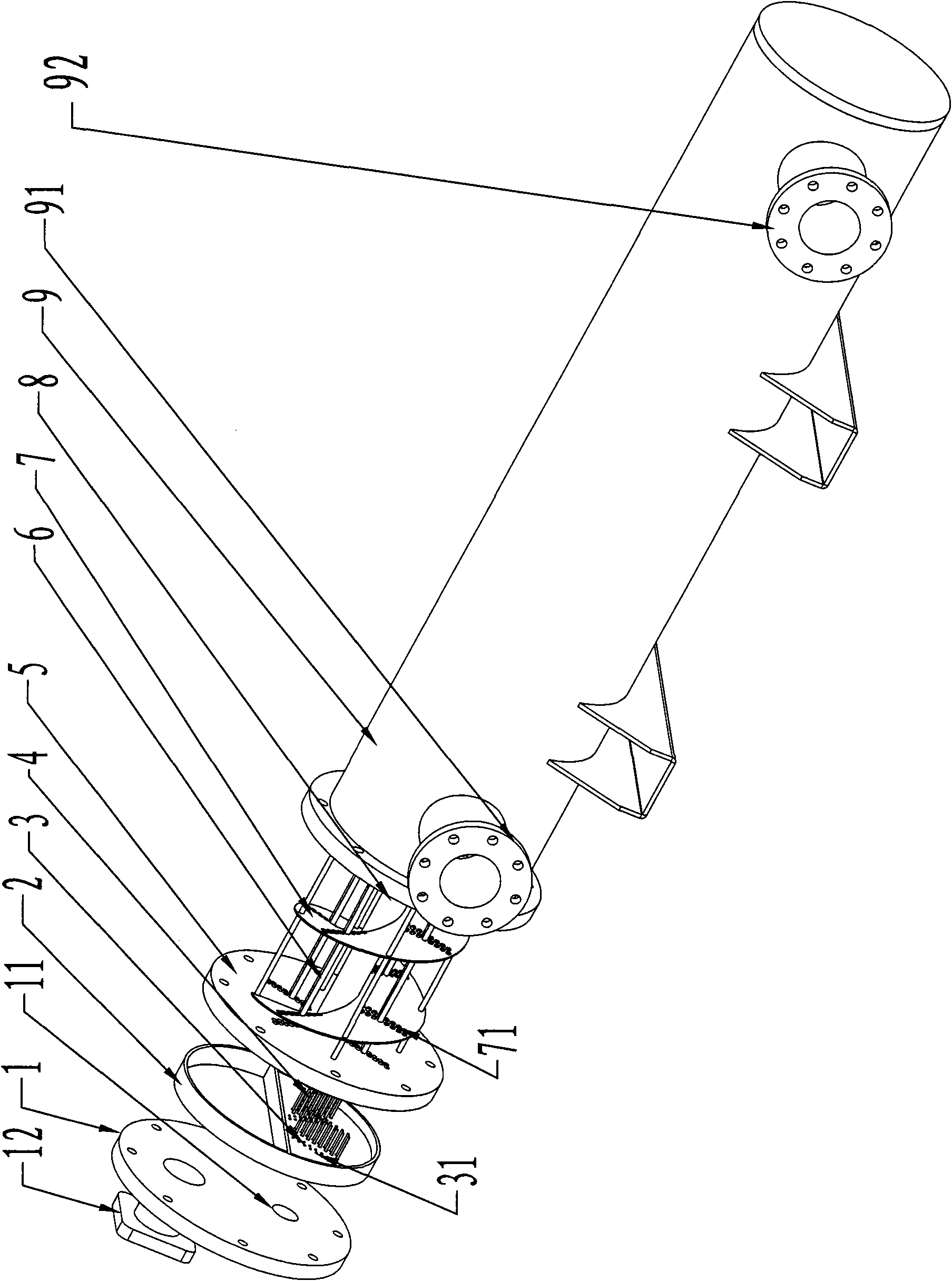

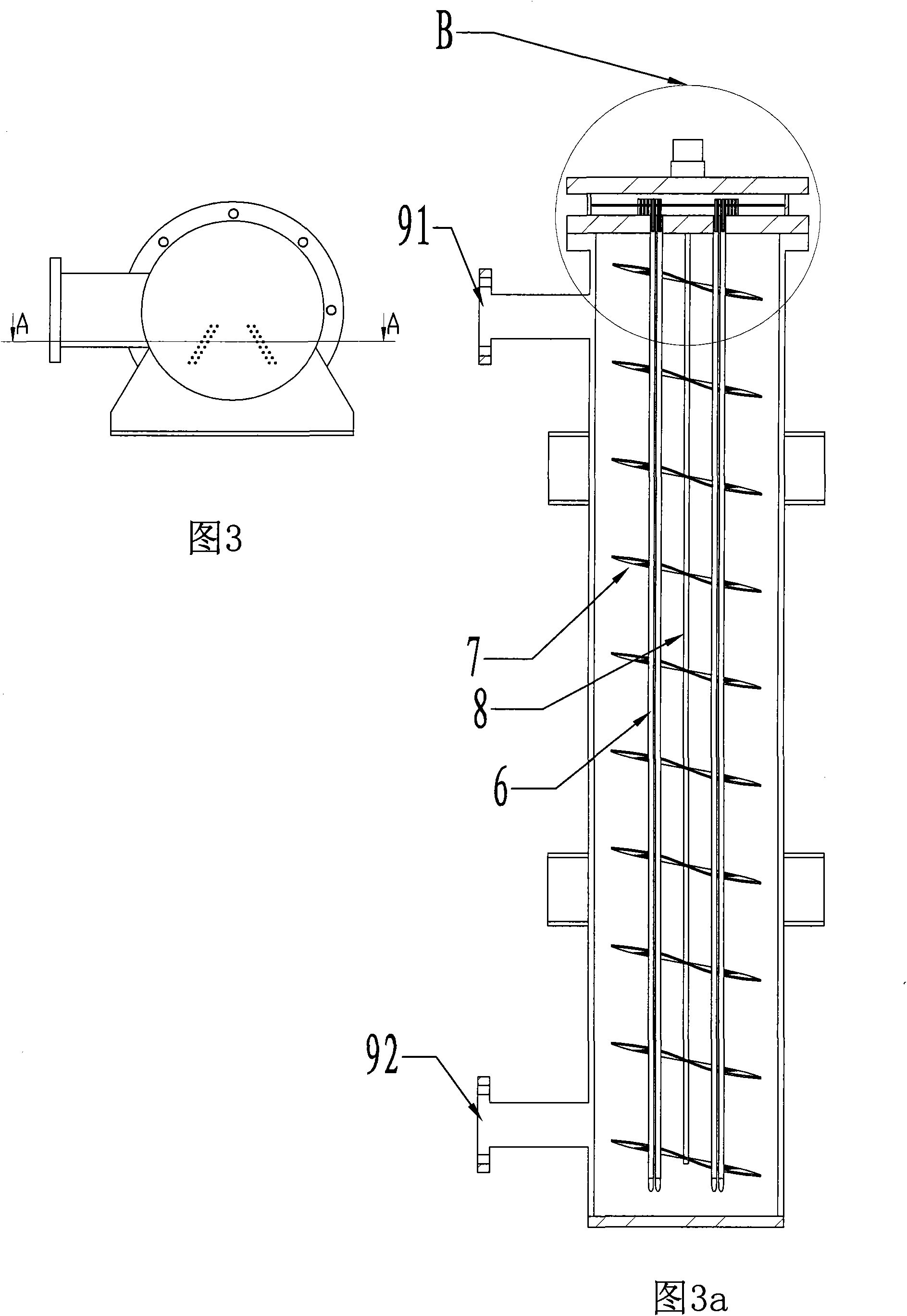

[0022] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0023] In this embodiment, the present invention is used as a "dry cold-only evaporator" in refrigeration as an example, as figure 2 As shown, the whole shell-and-tube heat exchanger system is divided into two kinds of working medium strokes: refrigerant stroke and brine stroke.

[0024] In the refrigerant stroke: the low-temperature and low-pressure refrigerant liquid enters the lower half of the tube box 2 from the refrigerant inlet 11 arranged at the lower part of the end plate 1, and a liquid separator 3 is arranged in the lower half of the tube box 2. The liquid plate 3, the bottom half of the tube box 2 and the end plate 1 form a narrower space 21, and in this space 21, the liquid is evenly distributed to some liquid pipes 4 arranged on the liquid separator plate (such as Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com