Double-working condition liquid cold water unit

A technology for chillers and liquid ice, applied in the field of liquid ice ice making and liquid ice chillers with dual working conditions, can solve the problems of inability to guarantee the quality of liquid ice, poor cooling effect, limited ice making capacity, etc. Effects of time, ease of movement, ease of flow control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below with reference to the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

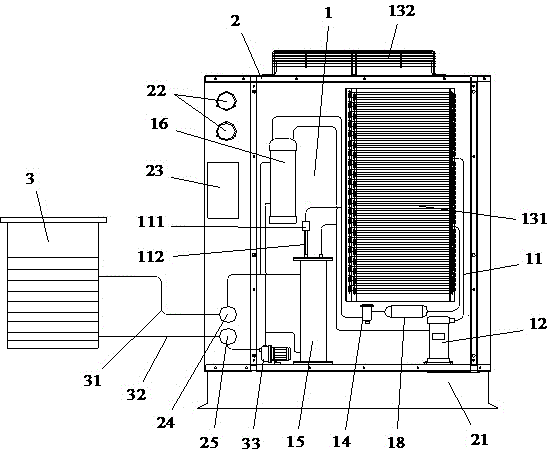

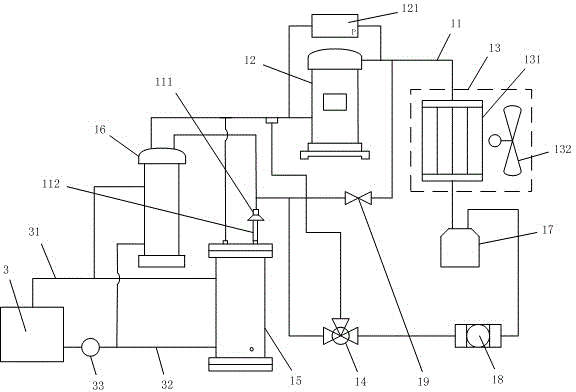

[0016] Example figure 1 and figure 2 As shown, a dual working condition liquid ice cooling water unit includes a liquid ice preparation system 1 installed in a metal box 2 and an ice water storage tank 3 connected outside the metal box 2, and is characterized in that: the liquid ice The preparation system 1 is composed of a refrigeration compressor 12, an air-cooled condenser 13, a thermal expansion valve 14, an ice crystal device 15 and a titanium pre-cooling heat exchanger 16 connected in sequence by a refrigerant pipe 11. The heat exchanger 16 is arranged in parallel, the ice crystal device 15 and the titanium pre-cooling heat exchanger 16 form an ice water circulation loop with the ice water storage tank 3 through the ice water outlet pipe 31 and the ice water return...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com