Novel energy-saving mobile ice producer

An ice maker, a new type of technology, is applied in the direction of ice making, ice making, lighting and heating equipment, etc. It can solve the problems of high power consumption of equipment, complicated ice making process, and large loss of cooling capacity, so as to improve quality and ensure Cooling effect, effect of increasing circulation volume and flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Now in conjunction with accompanying drawing, the present invention will be further described:

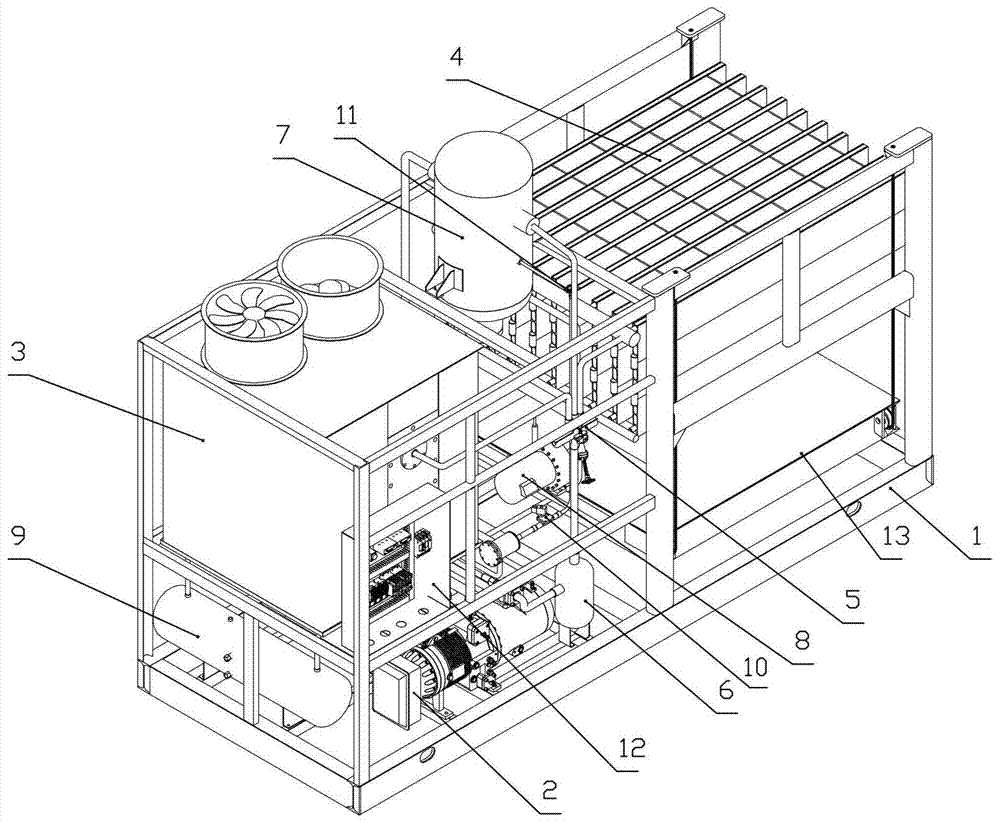

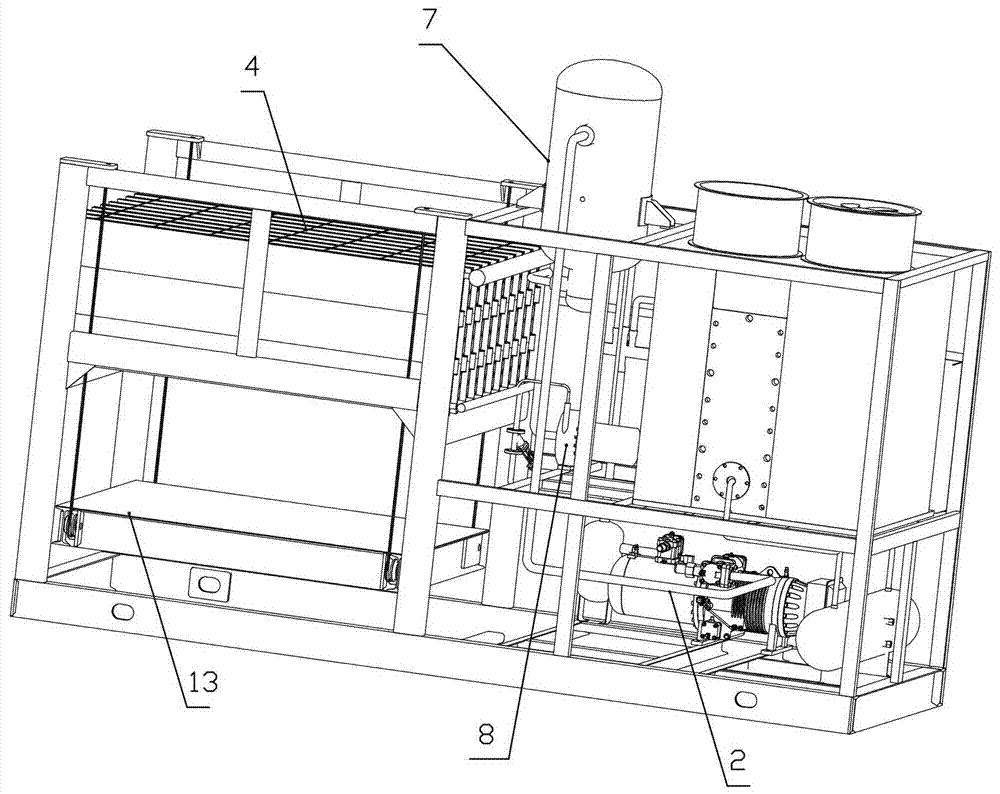

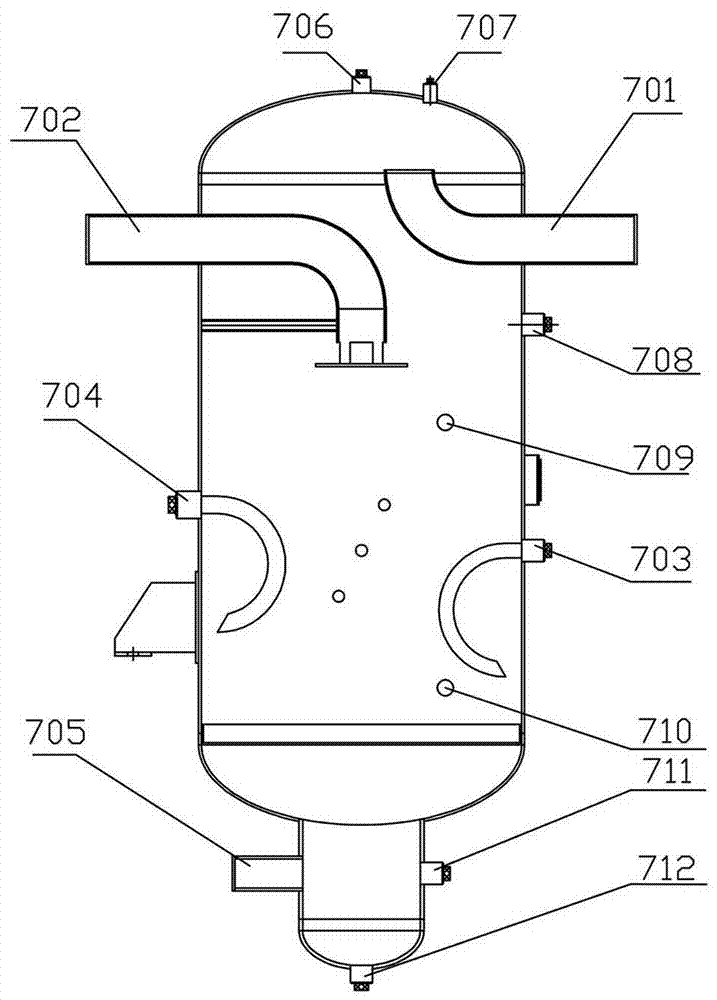

[0025] refer to figure 1 and figure 2 As shown, a new energy-saving mobile ice machine described in this embodiment includes a frame 1, a refrigeration compressor 2, a condenser 3, a direct cooling ice mold 4, a four-way valve 5, an oil separator 6, a circulation Barrel 7, fluorine pump 8, liquid storage barrel 9, solenoid valve 10, throttle valve 11, control box 12 and lifting table 13, wherein said direct cooling ice mold 4 includes an evaporator, and the evaporator is provided with cooling liquid aisle.

[0026] The refrigeration compressor 2 is fixed on the lower left side of the frame 1, the liquid storage barrel 9 is located on the left side of the refrigeration compressor 2 and is fixed on the lower left side of the frame 1, and the oil separator 6 is located on the right side of the refrigeration compressor 2 and is fixed on the The lower left side of the frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com