Multi-disc liquid distributor

A liquid distributor and multi-disc technology, which is applied in chemical instruments and methods, chemical/physical/physical chemical processes, chemical/physical processes, etc., can solve the problem of poor distribution uniformity of liquid distributors and difficulties in installation and maintenance of trough distributors , Pipe distributor with more mist and other problems, to achieve the effect of light weight, convenient installation and maintenance, and more liquid distribution points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The gas cooling tower of a certain gas purification device is a packed tower with a glass fiber reinforced plastic shell, and the inner diameter of the tower at the packing layer is 5 meters. The gas entering the tower is water-saturated wet gas, and the actual flow rate of the gas exiting the tower is 120km 3 / h, use 1150m 3 / h of acidic water to cool the gas, cooling the gas temperature from 76°C to 38°C. The spray density of the liquid is 51(m 3 / h) / m 2 .

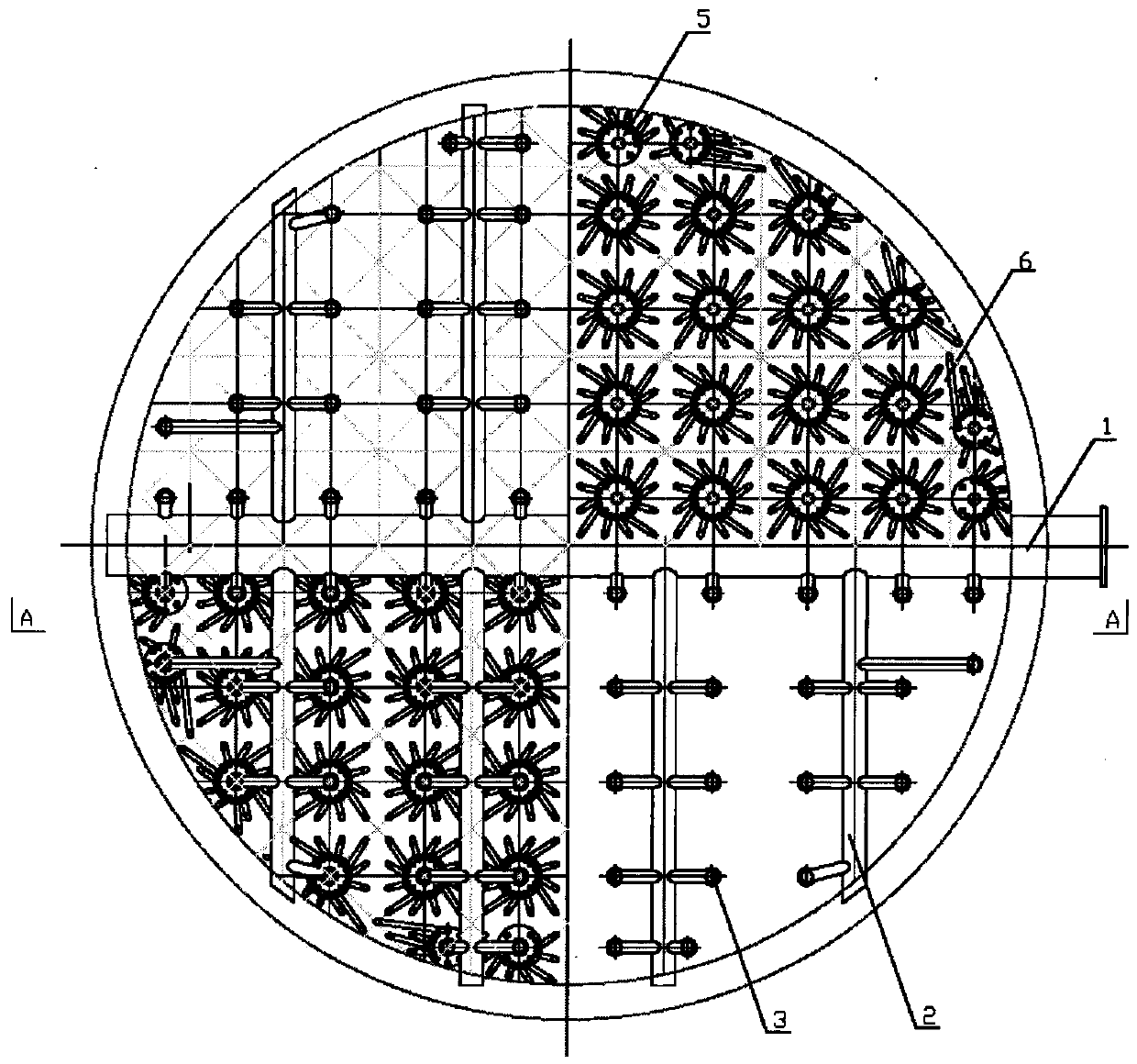

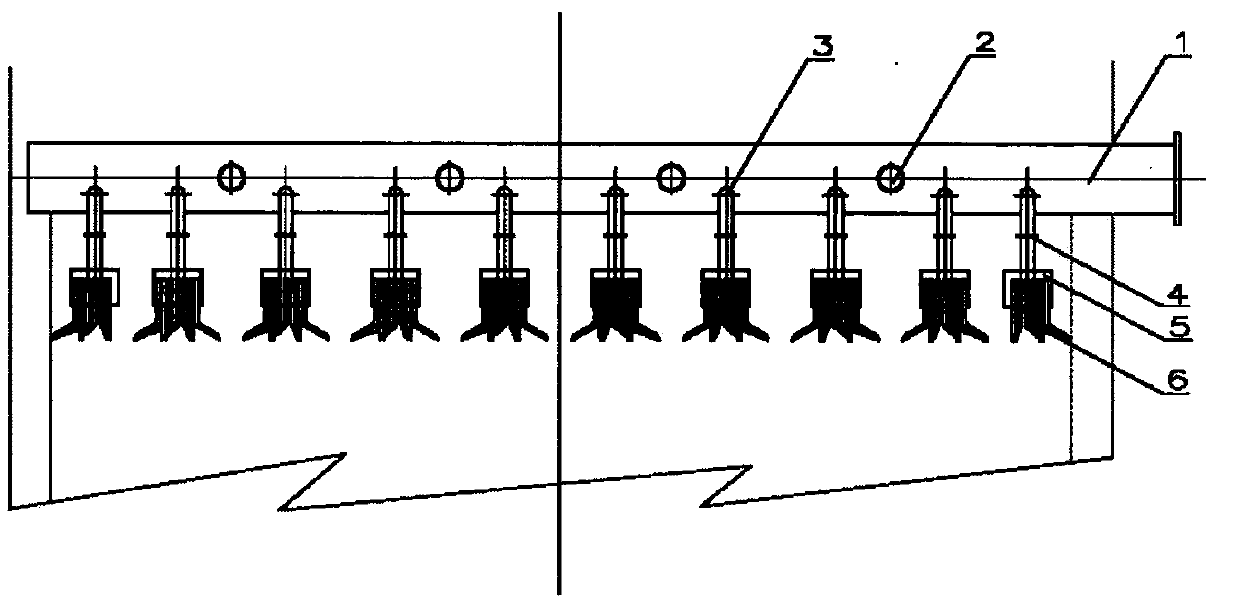

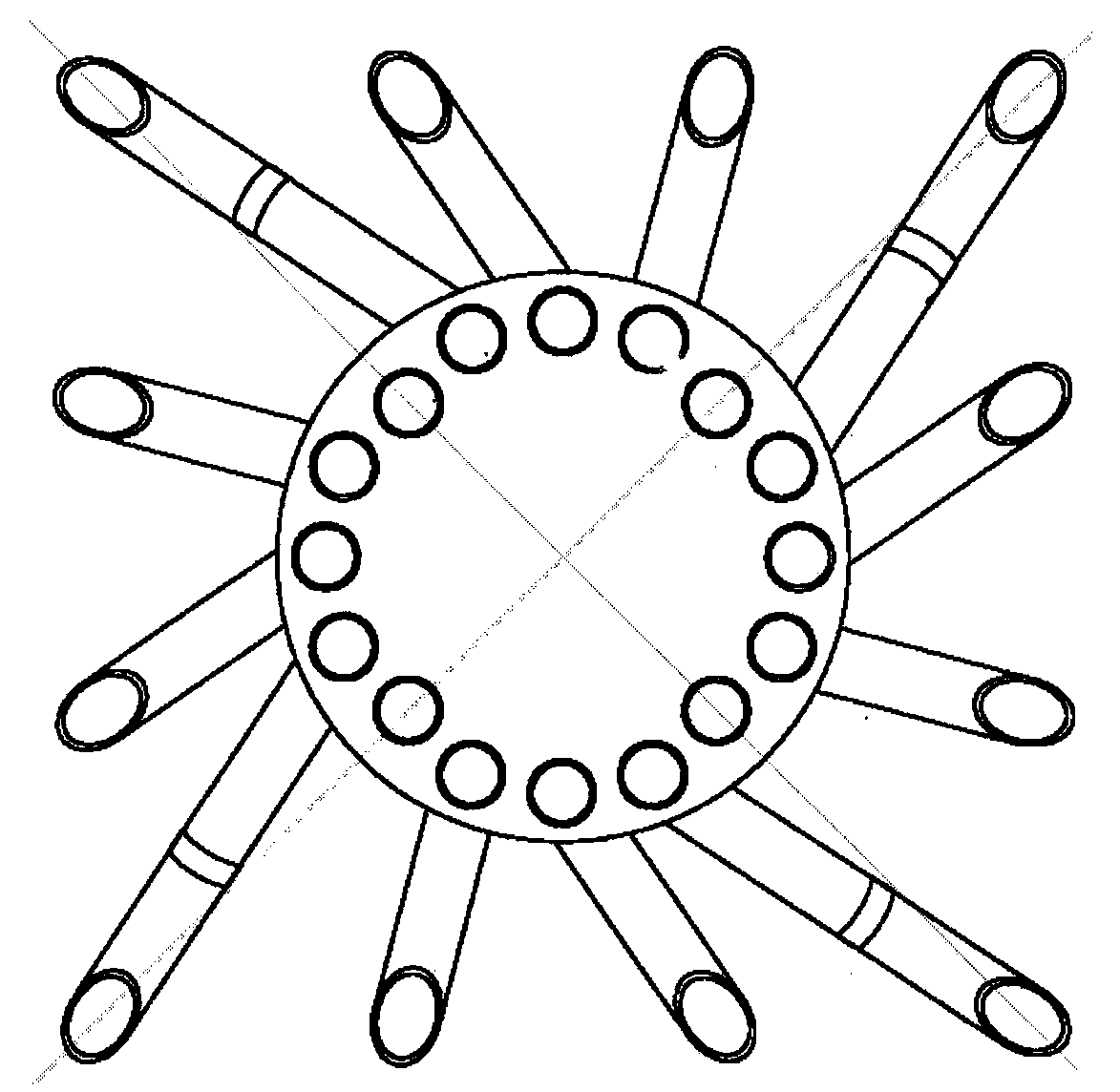

[0029] A multi-disc liquid distributor is installed on the surface of the packing to distribute the acidic water, including the main liquid inlet pipe, the liquid inlet branch pipe, the liquid distribution pipe, the flow-restricting orifice plate, the liquid separation dish, and the liquid discharge pipe. The liquid drop pipe is inserted into the liquid distribution plate, the liquid separation plate is hung on the liquid distribution pipe, the flow limiting orifice plate is installed in the liquid distributio...

Embodiment 2

[0033] The sulfur trioxide absorption tower of a sulfuric acid plant is a packed tower with carbon steel lining bricks. The inner diameter behind the lining bricks at the packing layer is 6.8 meters, the height of the main packing is 2.5 meters, and there is a 0.2-meter-high defoaming layer above the main packing layer. filler. Sulfur trioxide in the gas is absorbed by sulfuric acid with a concentration of 98.3%. The acid volume in the upper tower is 660m3 / h, and the spray density is 25(m3 / h) / m2.

[0034]Install a multi-disc liquid distributor on the surface of the packing to distribute sulfuric acid, including the liquid inlet main pipe (namely the acid inlet pipe), the liquid inlet branch pipe (namely the acid inlet branch pipe), the liquid distribution pipe (namely the acid distribution pipe), the restricting orifice plate, Separating plate (namely acid plate), downpipe (ie acid drop pipe). The acid drop pipe is inserted into the acid distribution plate, the acid distribut...

Embodiment 3

[0037] The first absorption tower after the moisture absorption tower of the semi-dry acid production plant is a packing tower with carbon steel lining bricks. The inner diameter behind the lining bricks at the packing layer is 5 meters, the height of the main packing is 2.3 meters, and there is still 0.2 meters high above the main packing layer Defoaming layer packing. Sulfuric acid with a concentration of 98.5% is used to absorb sulfur trioxide, water and sulfuric acid vapor remaining in the gas. The acid volume in the upper tower is 80m3 / h, and the spray density is 4(m3 / h) / m2.

[0038] Install a multi-disk liquid distributor on the packing surface to distribute sulfuric acid, including the acid inlet main pipe, acid inlet branch pipe, acid distribution pipe, flow-restricting orifice plate, acid distribution disc, and acid drop pipe. The acid drop pipe is inserted into the acid distribution plate, the acid distribution plate is hung on the acid distribution pipe, the flow li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com