Micro-channel heat exchanger and mounting method

A micro-channel heat exchanger, an integrated technology, applied in the direction of heat exchanger shell, heat exchange equipment, evaporator/condenser, etc., can solve the problem of easy deformation of baffle groove, increase of product leakage, and deterioration of header strength and other problems, to achieve the effect of high connection strength, avoid leakage, and facilitate assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

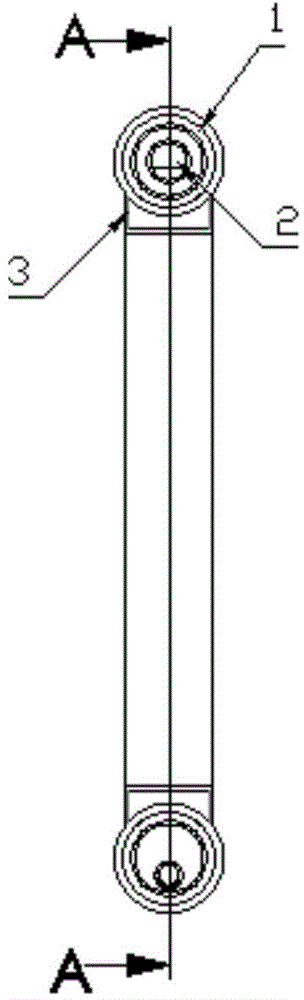

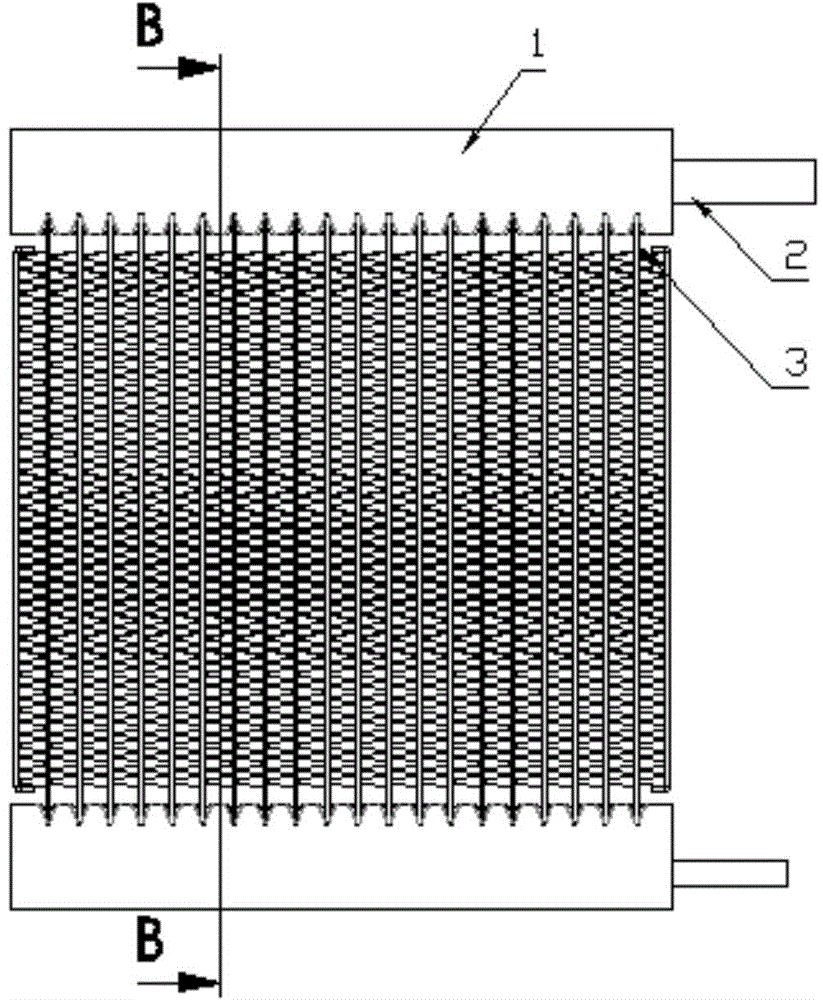

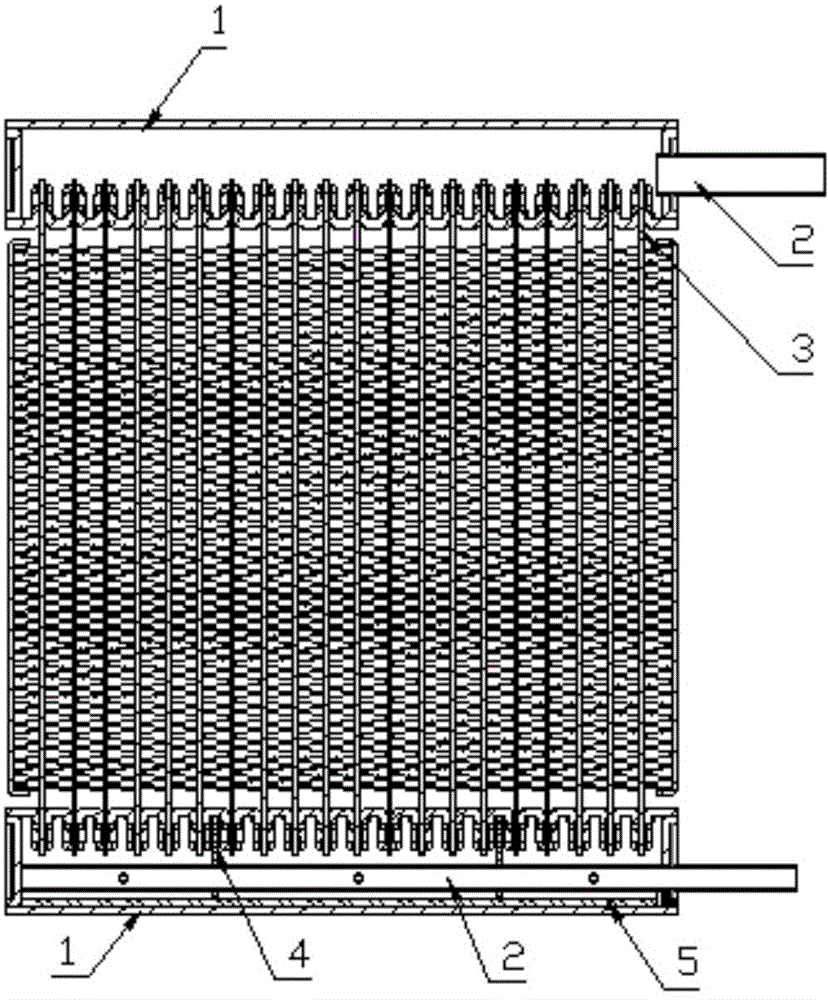

[0029] The following combination Figure 1 to Figure 5 Embodiment 1 of the present invention will be specifically described.

[0030] A microchannel heat exchanger, comprising a header 1 and a distribution pipe 2 arranged in the header 1, the distribution pipe 2 is provided with several distribution holes 21 along the axial direction, and the ends of the flat tubes 3 are inserted side by side In the collecting pipe 1, the distribution pipe 2 is integrally fixed with several partitions 4 along the axial direction, the distribution pipe 2 is movably inserted into the collecting pipe 1, and the distribution pipe 2 is also inserted into the collecting pipe 1 The fixed closure 5, the partition plate 4 cooperates with the closure 5 and the inner wall of the header 1 to separate several independent liquid separation areas inside the header 1.

[0031] The present invention still uses the separator 4 to separate several independent liquid separation areas inside the header 1, so as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com