Integrated type double cold source recombination heat exchange coil

A technology of heat exchange coils and dual cold sources, which is applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., to ensure the cooling effect and reduce the PUE value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

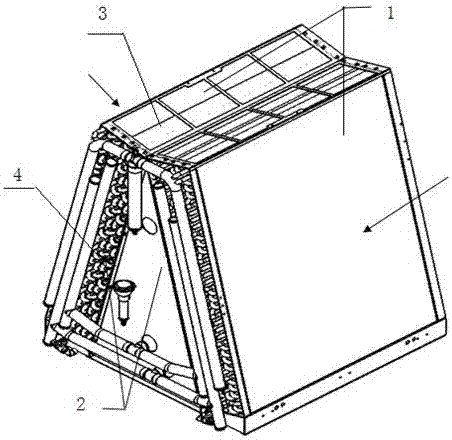

Embodiment 1

[0036] This embodiment provides an integral double cold source composite heat exchange coil, the cold source is chilled water from a central air conditioner, and the other cold source is refrigerant. Its main purpose is to ensure the normal operation of the dual cooling source computer room air conditioner using chilled water and refrigerant for cooling. Chilled water is the main cooling source. After the central air conditioner is turned off, it is supplemented with refrigerant cooling. Compared with all refrigerant cooling, the PUE value of the machine room is greatly reduced. Compared with all cooling water cooling, it can Ensure that the central air conditioner can achieve cooling effect after it is turned off, and ensure that the air conditioner in the computer room can run normally 24 hours a day, 365 days a year, which not only achieves the purpose of reducing energy consumption, but also ensures that the computer room is always smart without affecting the performance of...

Embodiment 2

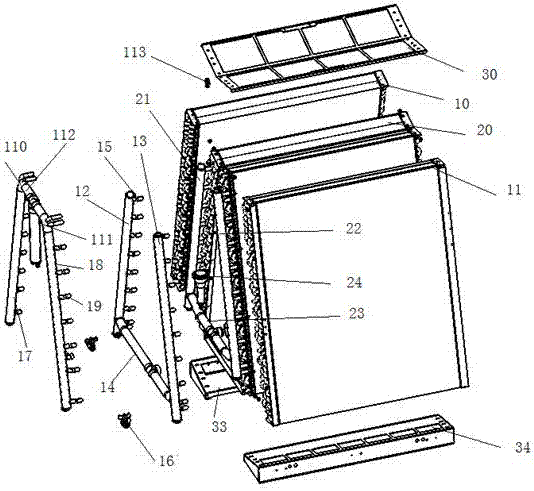

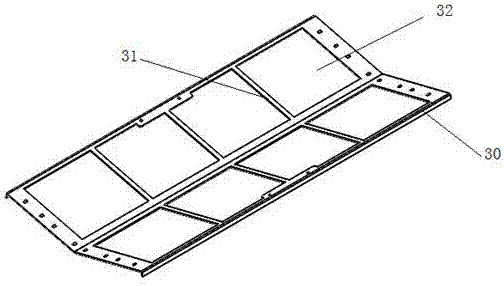

[0040] In this embodiment, on the basis of Embodiment 1, the connector 3 is optimized. The connector 3 includes a top plate 30 and a support plate. On the right core body 11, the middle is connected on the herringbone core body 20. The top plate is provided with a matts 31, and the matts 31 is provided with a hollow 32. The left and right cores adopt a "﹀" type integral matt roof, which can reduce the weight of the coil, and the "﹀" type can avoid air leakage in the gap between the left and right cores.

[0041] The support plate includes a left support plate 33 and a right support plate 34, the cross section of the support plate is trapezoidal, and a drainage hole 35 is arranged on the support plate, and the left support plate 33 is installed on the bottom of the left core 10 and the herringbone core 20, with drainage One end of the hole 35 is located at the bottom of the left core 10, the right support plate 34 is installed at the bottom of the right core 11 and the herring...

Embodiment 3

[0043] In this embodiment, on the basis of Embodiment 1, the refrigerant return header, chilled water inlet header, and chilled water outlet header are refined, and the specific structure is as follows:

[0044] The refrigerant return manifold includes a left refrigerant return pipe 21, a right refrigerant return pipe 22 and a horizontal refrigerant return pipe 23. One end of the horizontal refrigerant return pipe 23 is connected to the left refrigerant return pipe 21, and the other end is connected to On the right refrigerant return pipe 22, the horizontal refrigerant return pipe 23 is provided with an air return port, and the left refrigerant return pipe 21 communicates with the heat exchange coil 4 on the left side of the herringbone core body 20, and the right refrigerant The air return pipe 22 communicates with the heat exchange coil 4 on the right side of the herringbone core 20 .

[0045] The refrigerant distributor 24 communicates with the heat exchange coils 4 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com