Pure reverse flow dry evaporator device and use method thereof

A dry evaporator and countercurrent technology, which is applied in the direction of evaporator/condenser, heat exchanger shell, heat exchange equipment, etc., can solve the problems of reduced heat transfer performance, high processing cost, uneconomical, etc., to improve energy efficiency and Excellent heat transfer performance, low processing cost, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

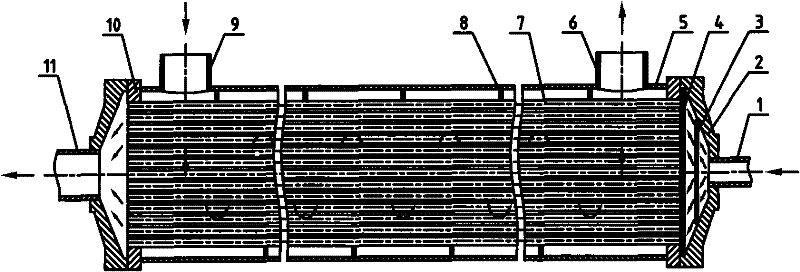

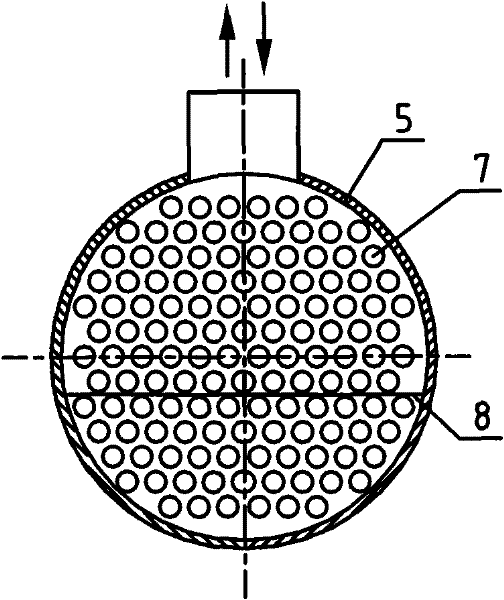

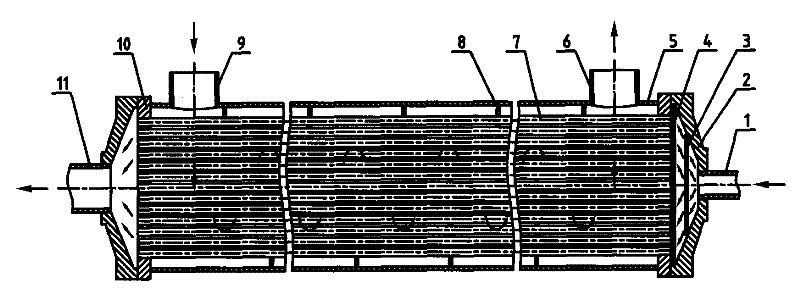

[0014] This embodiment is a pure countercurrent dry evaporator device used in a refrigeration air-conditioning unit with a cooling capacity of 460kW and a model of EGZ470HG. It is composed of a liquid inlet pipe 1, a pipe box 2, a primary distribution orifice plate 3, and a second Gradation distribution orifice plate 4, cylinder 5, brine outlet 6, evaporator tube bundle 7, baffle plate 8, brine inlet 9, tube plate 10 and air outlet pipe 11, etc. figure 1 , 2 The given structure is installed, wherein: the outer diameter of the cylinder 5 is Φ373mm, the length is 2400mm, and it is made of rolled steel plates; On the two-end tube plate 10 of the manufacturing cylinder 5, the middle of the axial outer end surface of the tube box 2 at one end is connected to the liquid inlet pipe 1 with an outer diameter of Φ38mm, and the middle of the outer axial end surface of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com