Heat collecting plate with high energy efficiency ratio and stable work

A heat-collecting panel and energy-efficiency ratio technology, applied in the field of solar heat-collecting panel manufacturing, can solve problems such as affecting the heat absorption of the panel surface, hindering the return of the compressor, and reducing the energy-efficiency ratio, so as to achieve sufficient heat absorption, reduce operating resistance, and extend the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

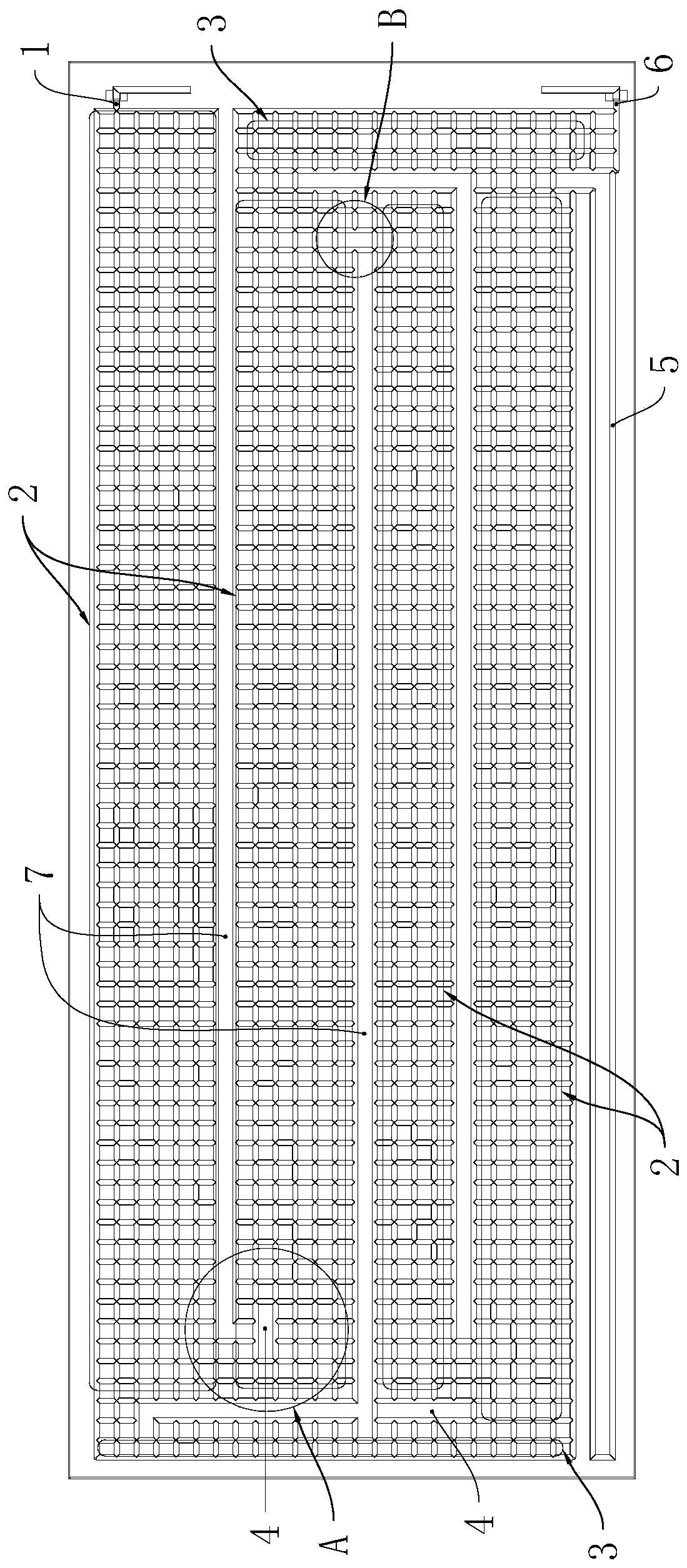

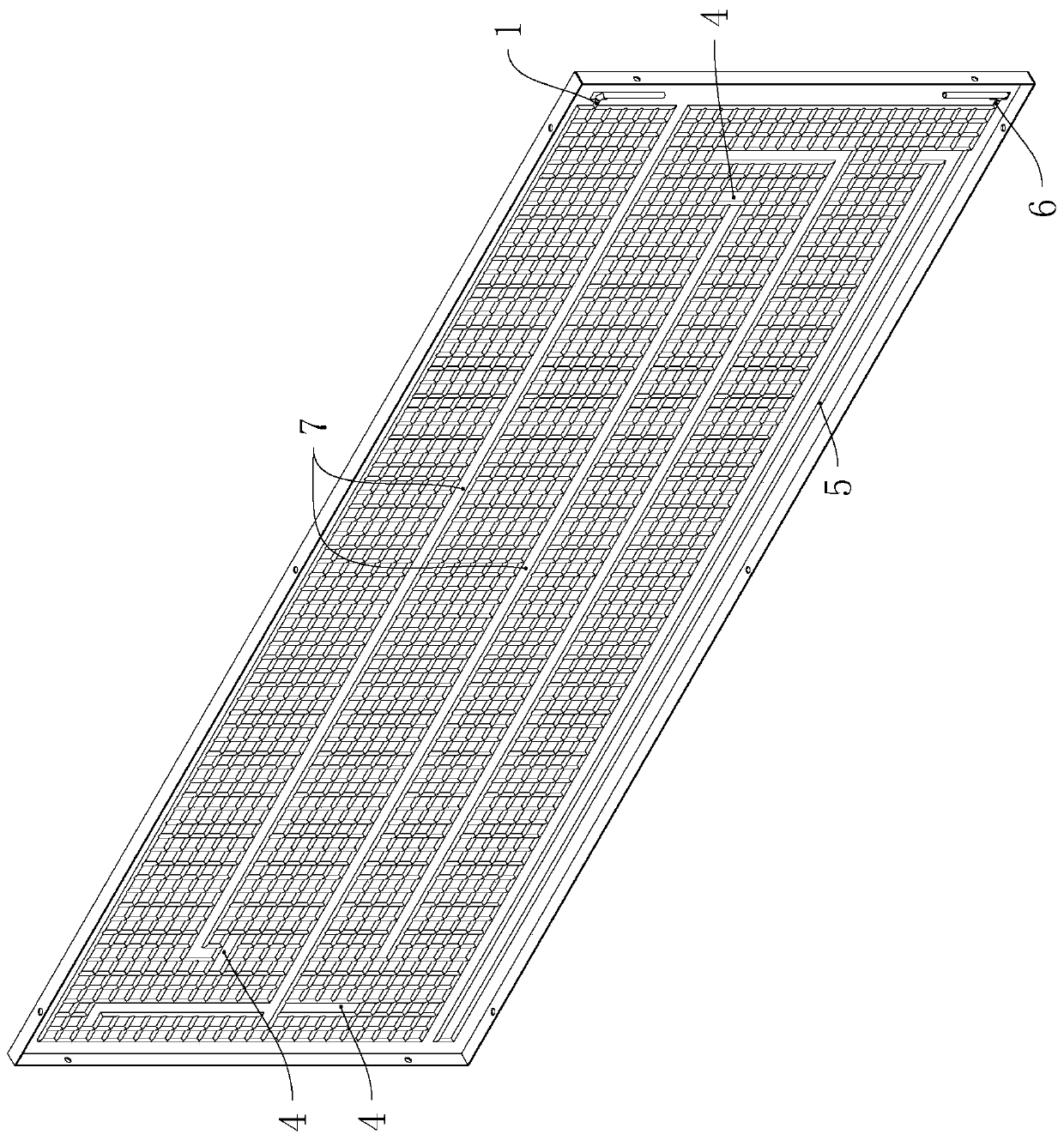

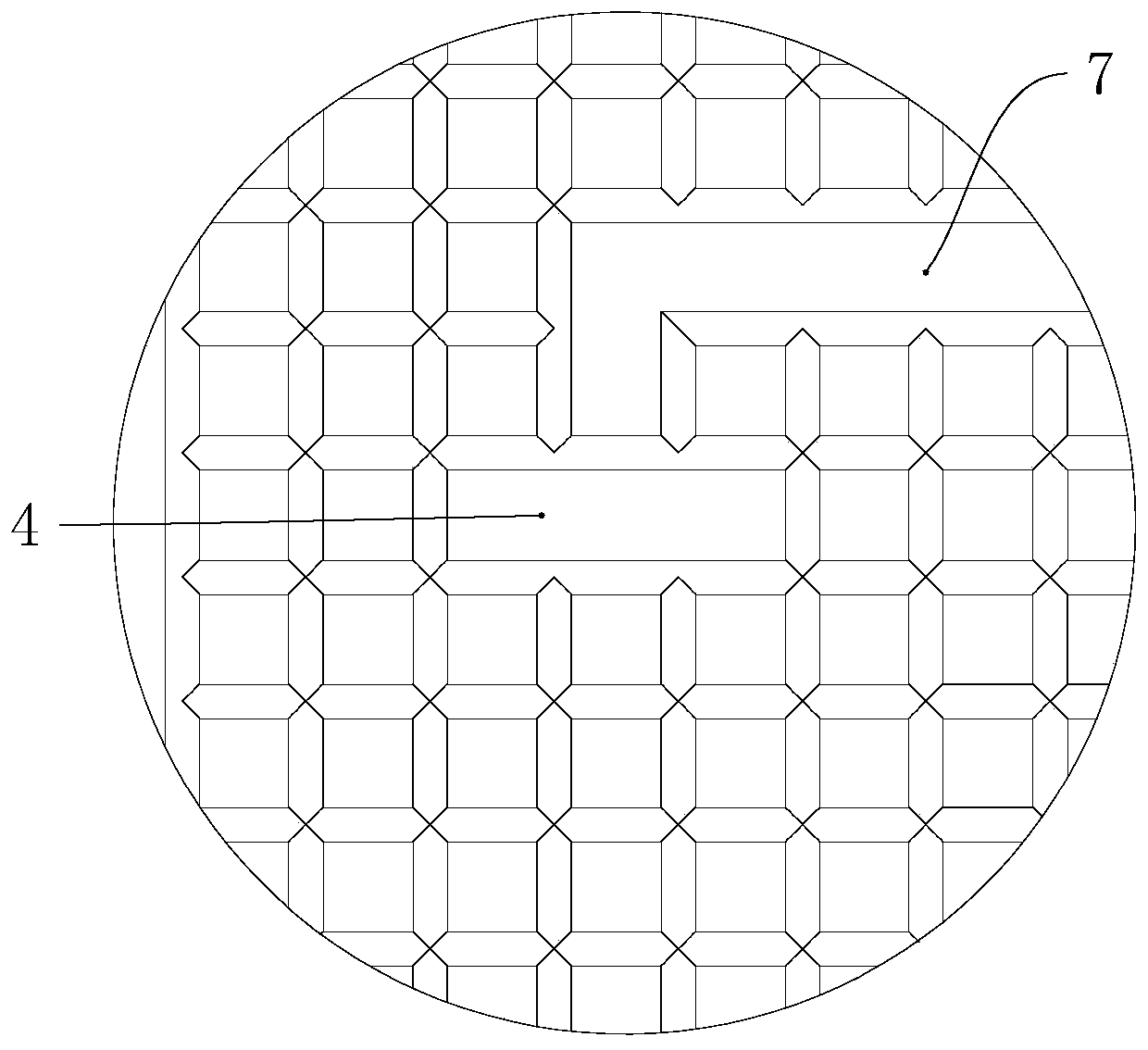

[0028] Embodiment 1: as figure 1 and figure 2 As shown, it shows a heat collecting plate with high energy efficiency ratio and stable operation, which includes a panel body, and the panel body is provided with grid-like distribution of working medium channels. In this embodiment, the panel is rectangular, and the working The flow channel is composed of two groups of pipes that criss-cross and communicate with each other, one group of pipes is arranged horizontally, and the other group of pipes is arranged vertically. When the panel body is in use, it is installed vertically on the outer surface of the wall or inclined in the open air through a fixing frame (in addition, the panel can also be curved according to the needs of the actual situation).

[0029] The panel body is also provided with a working medium inlet 1 and a working medium outlet 6 respectively connected to the working medium flow channel, the working medium inlet 1 is located at the top of the working medium f...

Embodiment 2

[0036] Embodiment 2: as Figure 5 As shown, another embodiment of a heat collecting plate with high energy efficiency ratio and stable operation is shown. The main difference between embodiment 2 and embodiment 1 is that the evaporation zone 2 in embodiment 2 is equipped with a The extension part 8 for conveying the liquid working fluid in the horizontal direction. The extension part 8 is arranged horizontally, and several extension parts 8 are distributed step by step in the evaporation area 2 . During operation, the liquid working medium enters from the side of the evaporation zone 2 and spreads horizontally when passing through several extension flow parts 8 . The remaining features and structures are the same as those in Embodiment 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com