Method of detecting and compensating for injector variability with a direct injection system

a direct injection and injector technology, applied in the direction of liquid fuel feeders, machines/engines, electric control, etc., can solve the problems of cylinder torque output imbalance, piece-to-piece and time-to-time variability of engine systems, and increase the emission of tail pipes, so as to reduce the temperature sensitivity of fuel rails, increase correlation results, and reduce pump operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

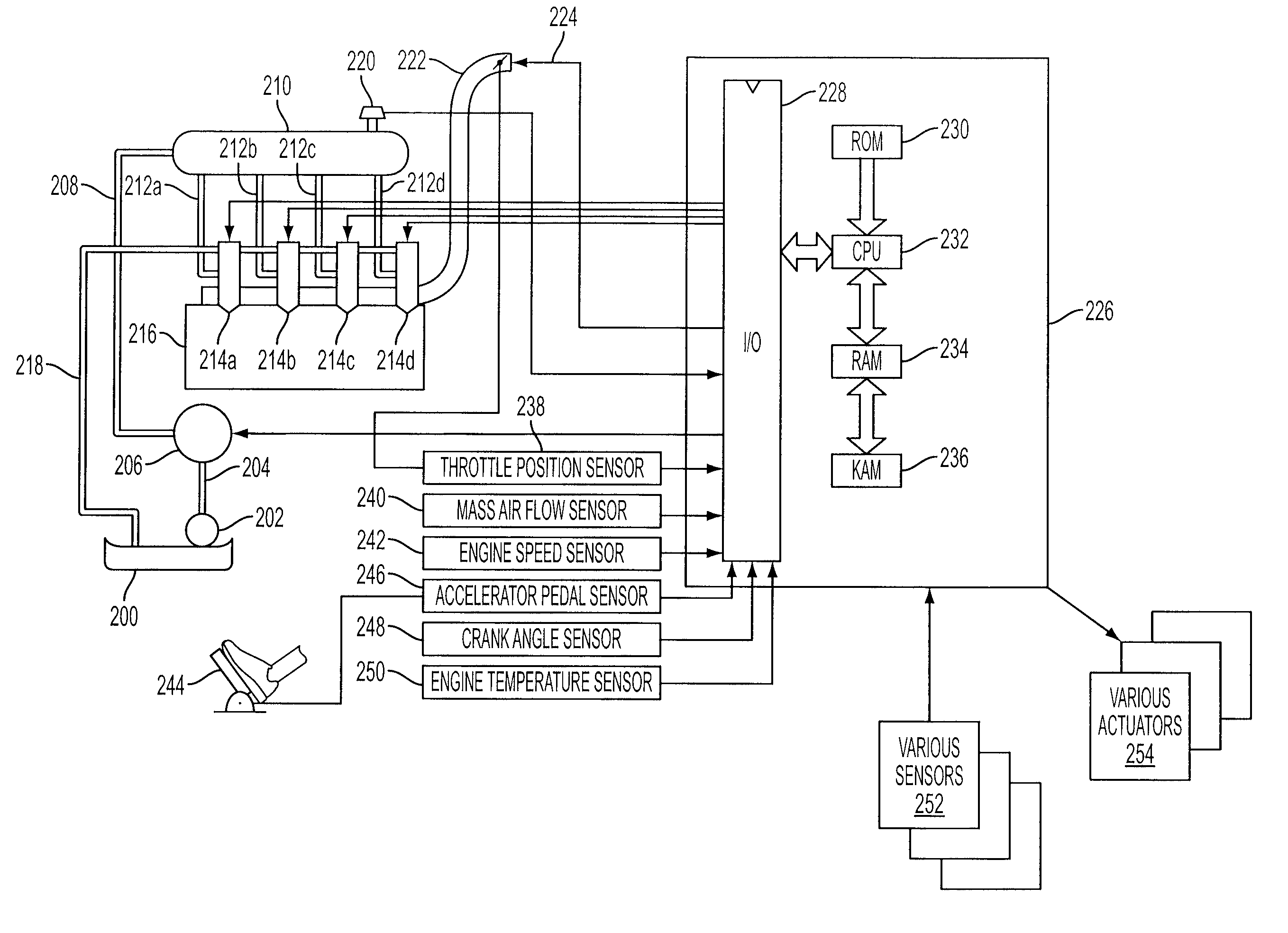

[0016]FIG. 1 shows one cylinder of a multi-cylinder engine, as well as the intake and exhaust path connected to that cylinder.

[0017]Continuing with FIG. 1, it shows a direct injection system, where engine 10 has direct fuel injection, as well as spark ignition. Internal combustion engine 10, comprising a plurality of combustion chambers, is controlled by electronic engine controller 12. Combustion chamber 30 of engine 10 is shown including combustion chamber walls 32 with piston 36 positioned therein and connected to crankshaft 40. A starter motor (not shown) may be coupled to crankshaft 40 via a flywheel (not shown), or alternatively direct engine starting may be used.

[0018]In one particular example, piston 36 may include a recess or bowl (not shown) to help in forming stratified charges of air and fuel, if desired. In some examples, a flat piston may be used.

[0019]Combustion chamber, or cylinder, 30 is shown communicating with intake manifold 44 and exhaust manifold 48 via respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com