Pulsation pressure decreased type pump for vehicle slip control system

a technology of a control system and a pump, which is applied in the direction of pulse equalisation, pump components, positive displacement liquid engines, etc., can solve the problem of vehicle occasionally slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

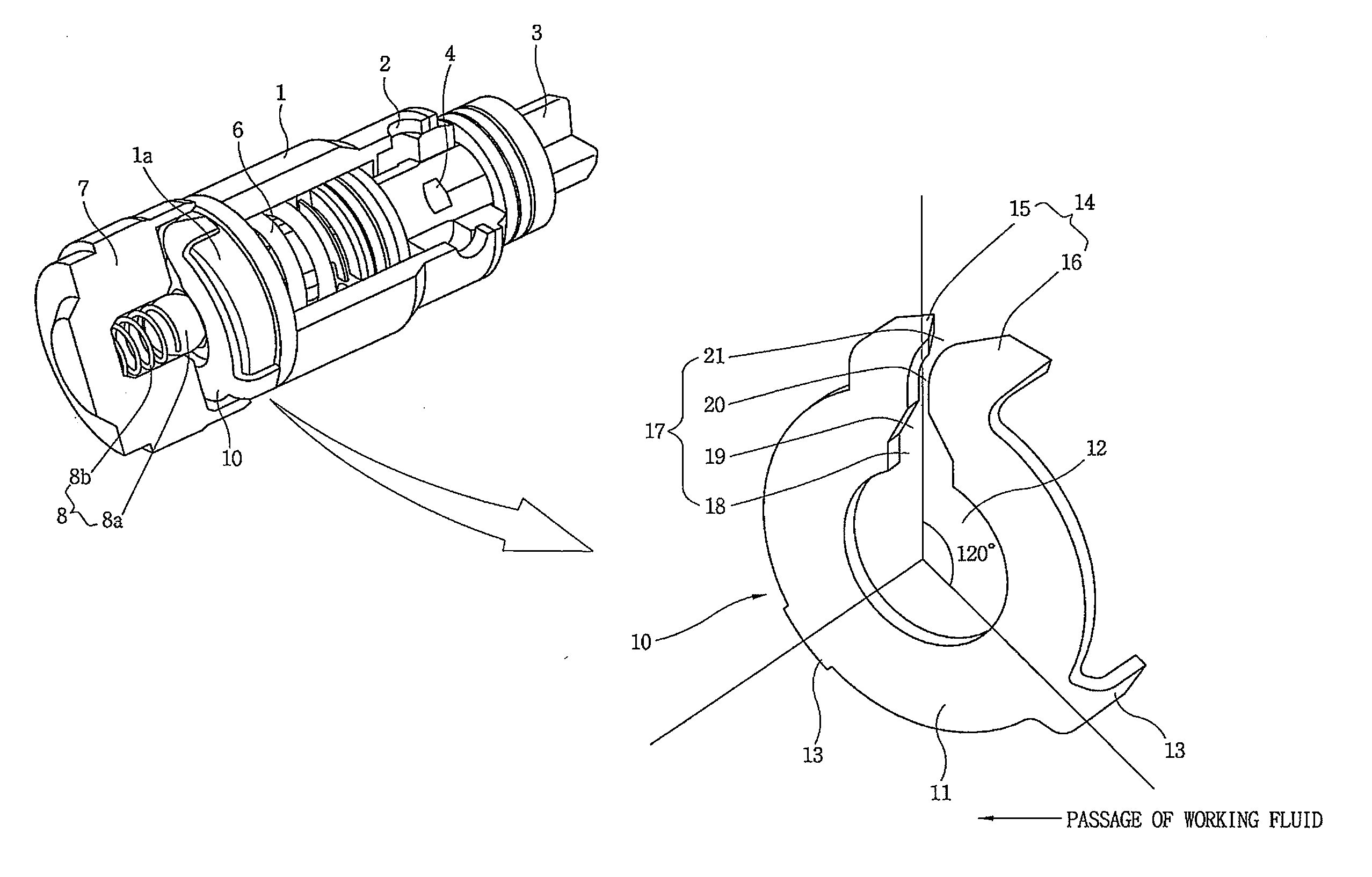

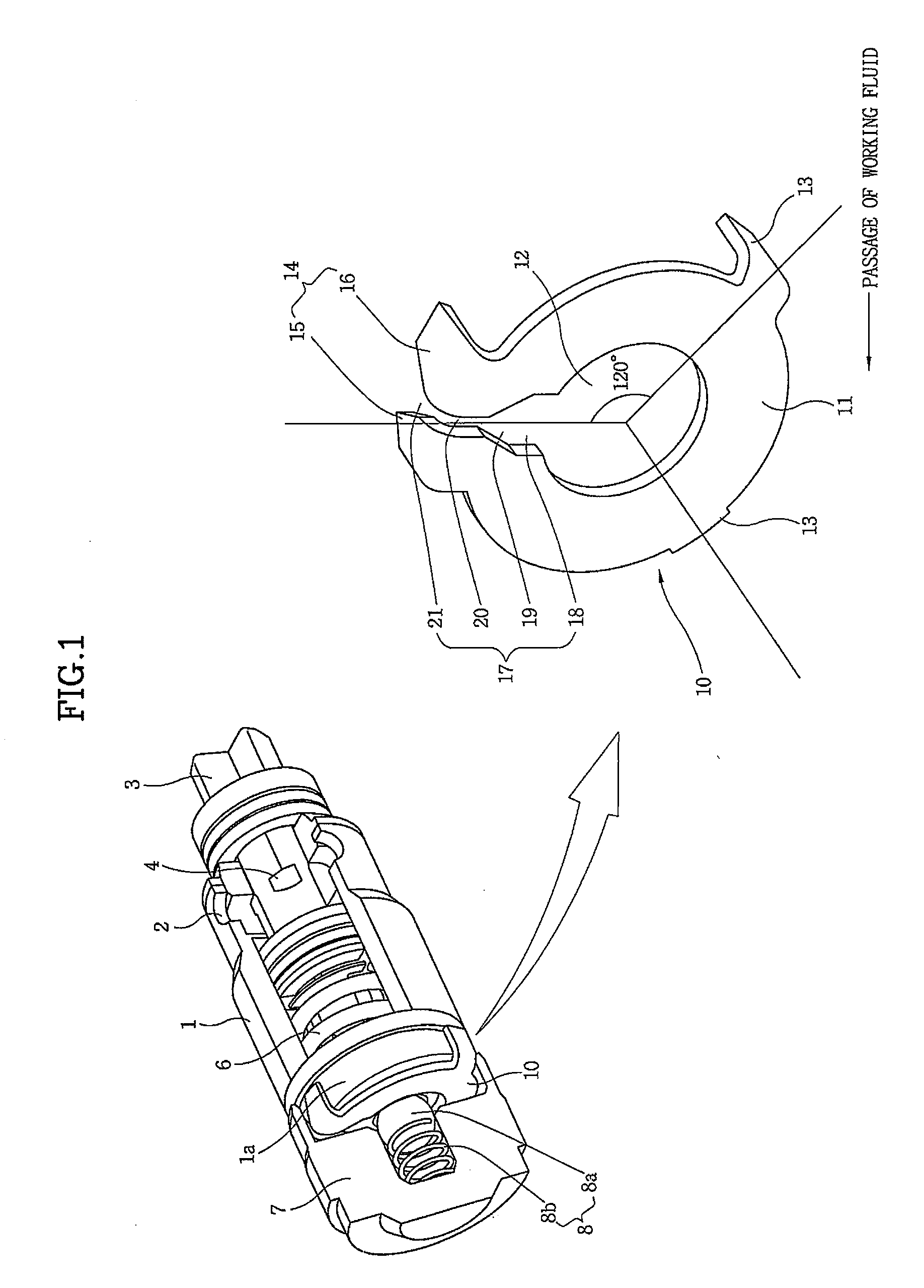

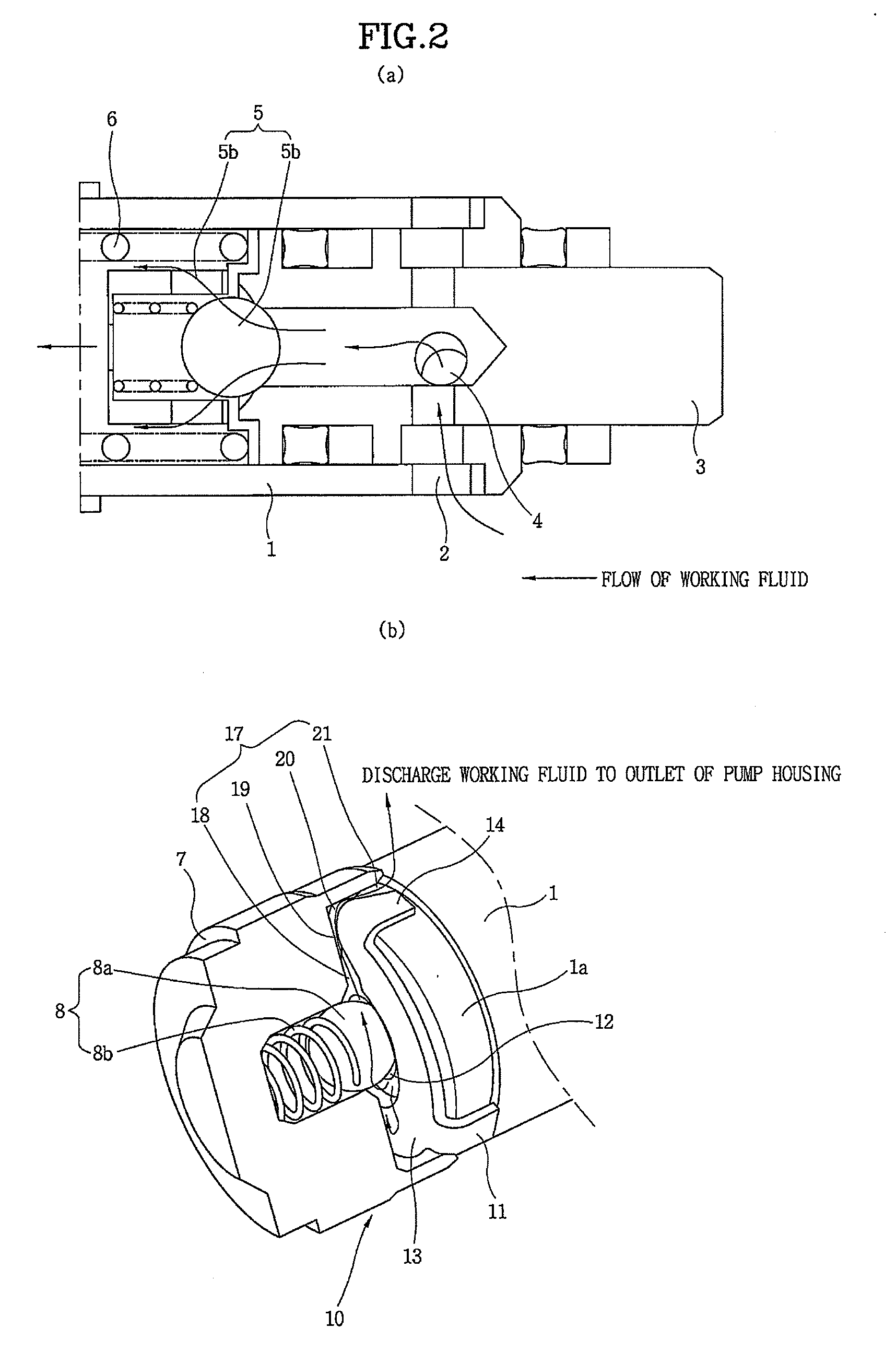

[0020]FIG. 1 is a view showing the structure of a pulsating pressure decreased type control valve for a vehicle slip control system according to an embodiment of the present invention. An oil control pump, which pumps and circulates oil used as a working fluid, of an electronically controlled brake system according to an embodiment of the present invention includes a sleeve 1, a piston 3, an inlet check valve 5, an outlet check valve 8, and an orifice 10. Sleeve 1 is fixed to a pump housing and provides a working fluid passage in the inside thereof. Piston 3 is elastically supported in sleeve 1 by an inner spring 6, and allows the working fluid to flow into the inside thereof during the operation of the pump. Inlet check valve 5 is provided at the front end of piston 3 so as to discharge the working fluid into sleeve 1 by the pressure of the working fluid flowing into piston 3. Outlet check valve 8 is received in a cap 7 fixed to an end of sleeve 1, and opens or closes a discharge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com