Method for purifying chromatographic grade organic solvent methyl tertiary butyl ether

A technology of methyl tert-butyl ether and organic solvent, which is applied in the field of purification of chromatographic-grade organic solvent methyl tert-butyl ether, to achieve the effects of saving manpower, significant economic benefits, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

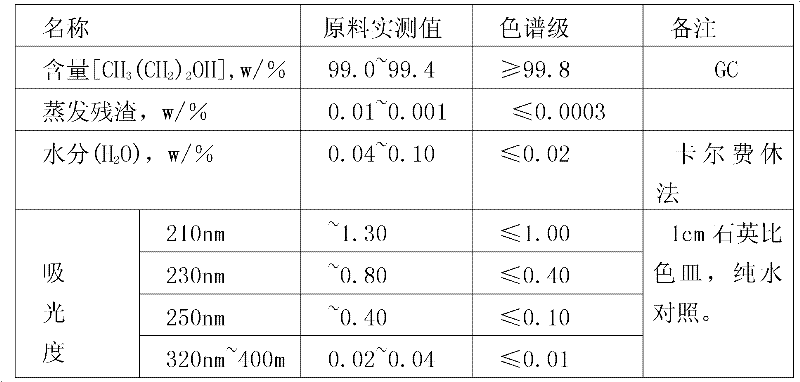

[0024] A purification method of chromatographic grade organic solvent methyl tert-butyl ether, the steps are as follows:

[0025] (1) Adsorption: Lift the raw material methyl tert-butyl ether (99.0% to 99.4%) to the top of the adsorption column. The two adsorption columns are the same: 1.5M in height, 4.0cm in diameter, and equipped with 100-mesh Alumina and silica gel adsorbent, the column capacity is 4 / 5 of the column height, and the raw material of methyl tert-butyl ether flows through the two columns in turn at a speed of 30mL / min for adsorption;

[0026] In this step, the methyl tert-butyl ether in the adsorption column is in full contact with the alumina and silica gel adsorbent, and most of the organic impurities and some water are removed by adsorption. , enter the next step operation, and remove the fraction before adsorption;

[0027] (2) Drying: the effluent in step (1) is put into the drying column, the specifications of the drying column and the packing volume ar...

Embodiment 2

[0032] A purification method of chromatographic grade organic solvent methyl tert-butyl ether, the steps are as follows:

[0033] (1) Adsorption: Lift the raw material methyl tert-butyl ether (99.0% to 99.4%) to the top of the adsorption column. The two adsorption columns are the same: 1.5M in height, 4.0cm in diameter, and equipped with a particle size of about 200 Purpose Alumina and silica gel adsorbent, the column capacity is 4 / 5 of the column height, and the raw material of methyl tert-butyl ether is adsorbed at a speed of 80mL / min. After the adsorption liquid is nearly qualified, enter the next step; and remove impurities High pre-adsorption fraction;

[0034] (2) Drying: the effluent in step (1) is put into a drying column, the specifications of the drying column and the loading capacity are all the same as those of the adsorption column, and the oven-dried anhydrous calcium sulfate is loaded, and the flow rate is 100mL / min. Measure the water content of methyl tert-but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com