Preparation method of anhydrous calcium sulfate whisker

A whisker and calcium carbonate technology, which is applied in the preparation of anhydrous calcium sulfate whiskers and anhydrite whiskers, can solve problems such as uneven length-to-diameter ratio, crystal water, and harsh control conditions of production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

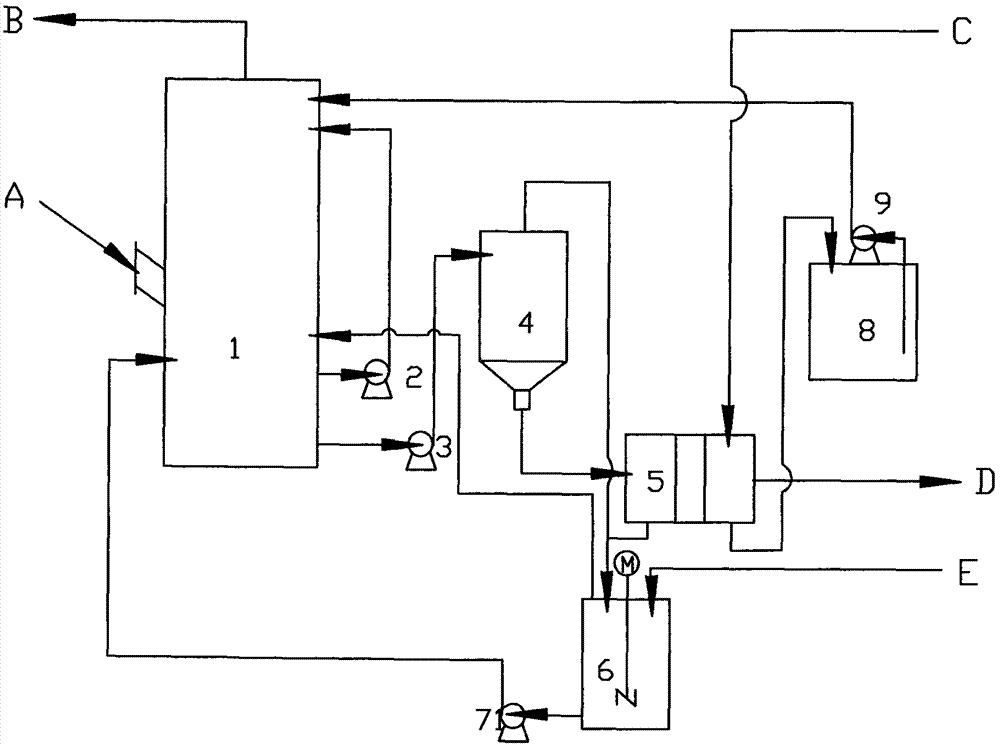

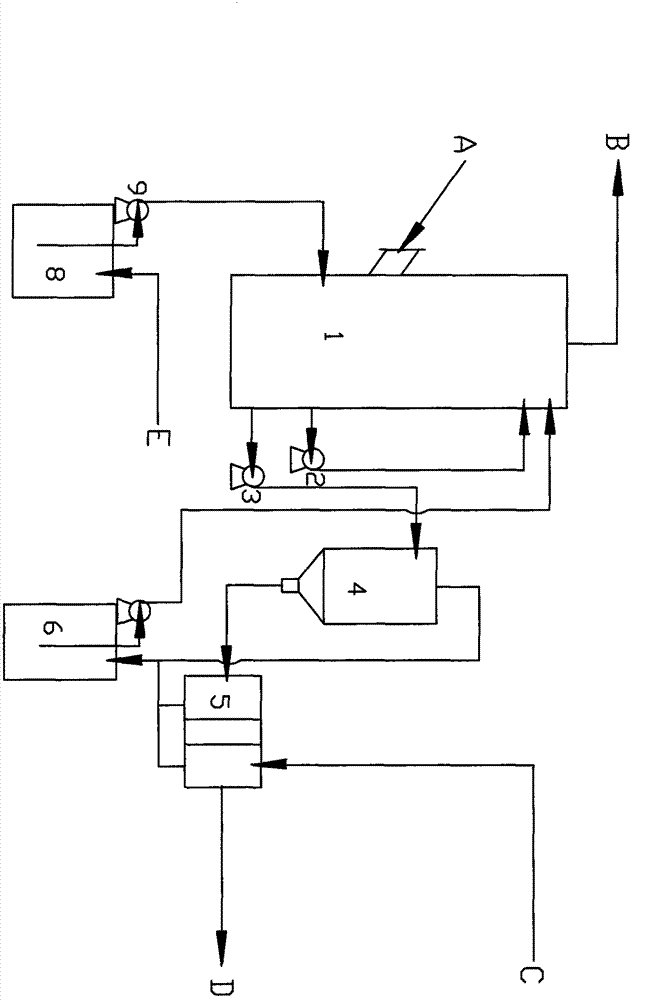

Method used

Image

Examples

Embodiment 1

[0015] Prepare 75ml of 25% (mass fraction) ammonium sulfate solution, weigh 1.0g of calcium carbonate and wet-grind the slurry, add it to the absorption bottle, put it in a 50℃ constant temperature water bath, and pass SO 2 (The concentration is 5%, N 2 In order to fill the gas, the flow rate is controlled to 100m1 / min), the reaction is carried out for 80 minutes, the calcium sulfite whiskers are obtained by filtration and drying, and then the anhydrous gypsum whiskers are obtained by high-temperature air reaction.

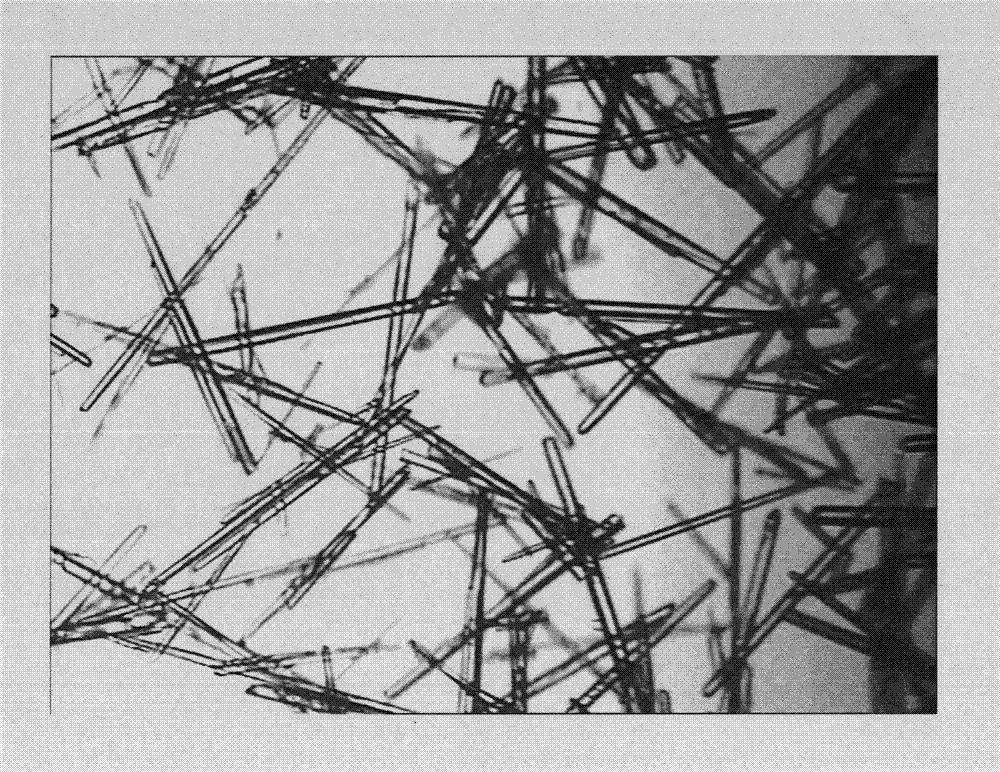

[0016] The anhydrous calcium sulfate whiskers obtained in Example 1 have a high aspect ratio of 30-200, and a high whiteness of over 90%.

Embodiment 2

[0018] Prepare 50ml of 25% (mass fraction) ammonium sulfate solution, add 3g of crystal aid to make a medium solution, weigh 0.5g of calcium carbonate and wet-grind the slurry, add it to the absorption bottle, and put it in a 50℃ constant temperature water bath. Into SO 2 (The concentration is 5%, N 2 In order to fill the gas, the flow rate is controlled to 100ml / min), the reaction is carried out for 50 minutes, and the calcium sulfite whiskers are obtained by filtration and drying, and then anhydrous gypsum whiskers are obtained by high-temperature air reaction.

[0019] The anhydrous calcium sulfate whiskers obtained in Example 2 have a high aspect ratio of 50-200 and a high whiteness of over 90%.

Embodiment 3

[0021] Prepare 25% (mass fraction) of 75ml of ammonium sulfate solution, weigh 0.8g of calcium hydroxide and wet-grind the slurry, add it to the absorption bottle, put it in a 50℃ constant temperature water bath, and pass SO 2 (The concentration is 5%, N 2 In order to fill the gas, the flow rate is controlled to 100ml / min), the reaction is carried out for 80 minutes, and the calcium sulfite whiskers are obtained by filtration and drying, and then anhydrous gypsum whiskers are obtained by the high-temperature air reaction.

[0022] The anhydrous calcium sulfate whiskers obtained in Example 3 have a high aspect ratio of 30-150, and a high whiteness of 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com