Method for preparing calcium sulfate whiskers

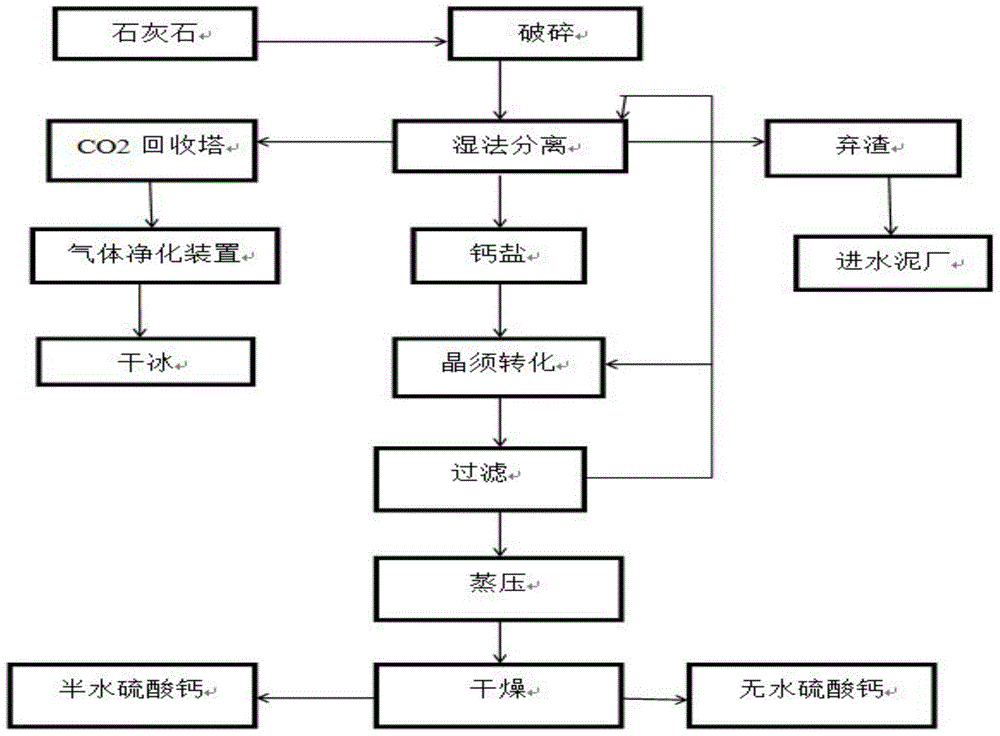

A technology for calcium sulfate whiskers and whiskers, which is applied in the field of preparation of calcium sulfate whiskers, can solve the problems of not being suitable for industrialized production, low output, and high energy efficiency, and achieve the effects of reducing calcination procedures, simple mining, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

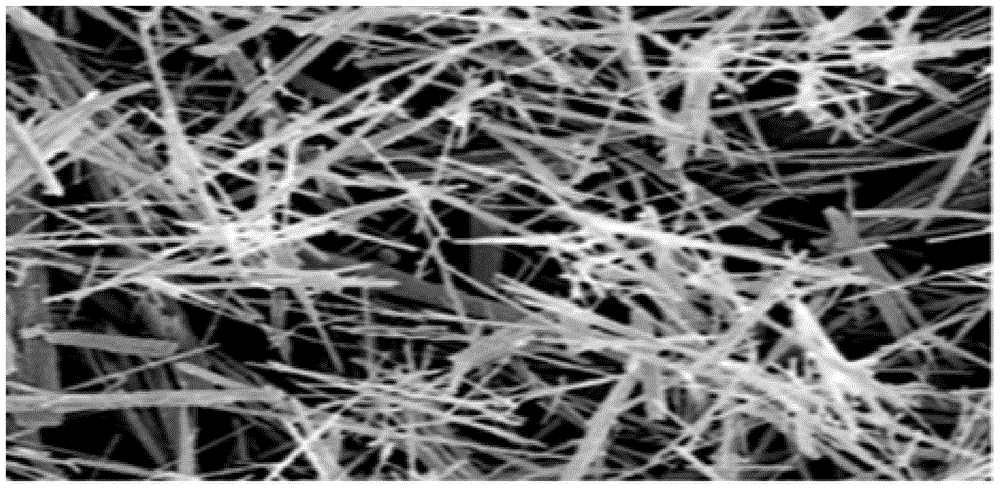

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0035] (1) Raw material: use limestone containing 90% to 98% calcium carbonate as raw material, grind the limestone into 46-100 mesh powder, send it to the leaching workshop for leaching, and leaching in the next process.

[0036] (2) Leaching: mix ground limestone with hydrochloric acid (concentration 15% to 30%) and recycled dilute hydrochloric acid to obtain a calcium chloride solution.

[0037](3) Slurry adjustment: adjust the calcium chloride solution to 1.5-3mol / L, use magnesium chloride as the transcrystal enzyme, and the content of magnesium chloride is 0.1-0.5mol / L.

[0038] (4) Crystallization at room temperature: add dilute sulfuric acid to the adjusted calcium chloride solution at room temperature, and crystallize under constant stirring. Filter and wash after whisker growth is complete. After filtering, return the acid-containing sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com