Process for preparing calcium sulphate whiskers by using flue gas desulfurization gypsum

A technology of calcium sulfate whisker and desulfurization gypsum, which is applied in separation methods, chemical instruments and methods, calcium/strontium/barium sulfate, etc., can solve the problems of insufficient utilization of desulfurization gypsum, etc., and achieves low production cost and ease of use. The effect of dyeing environment and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

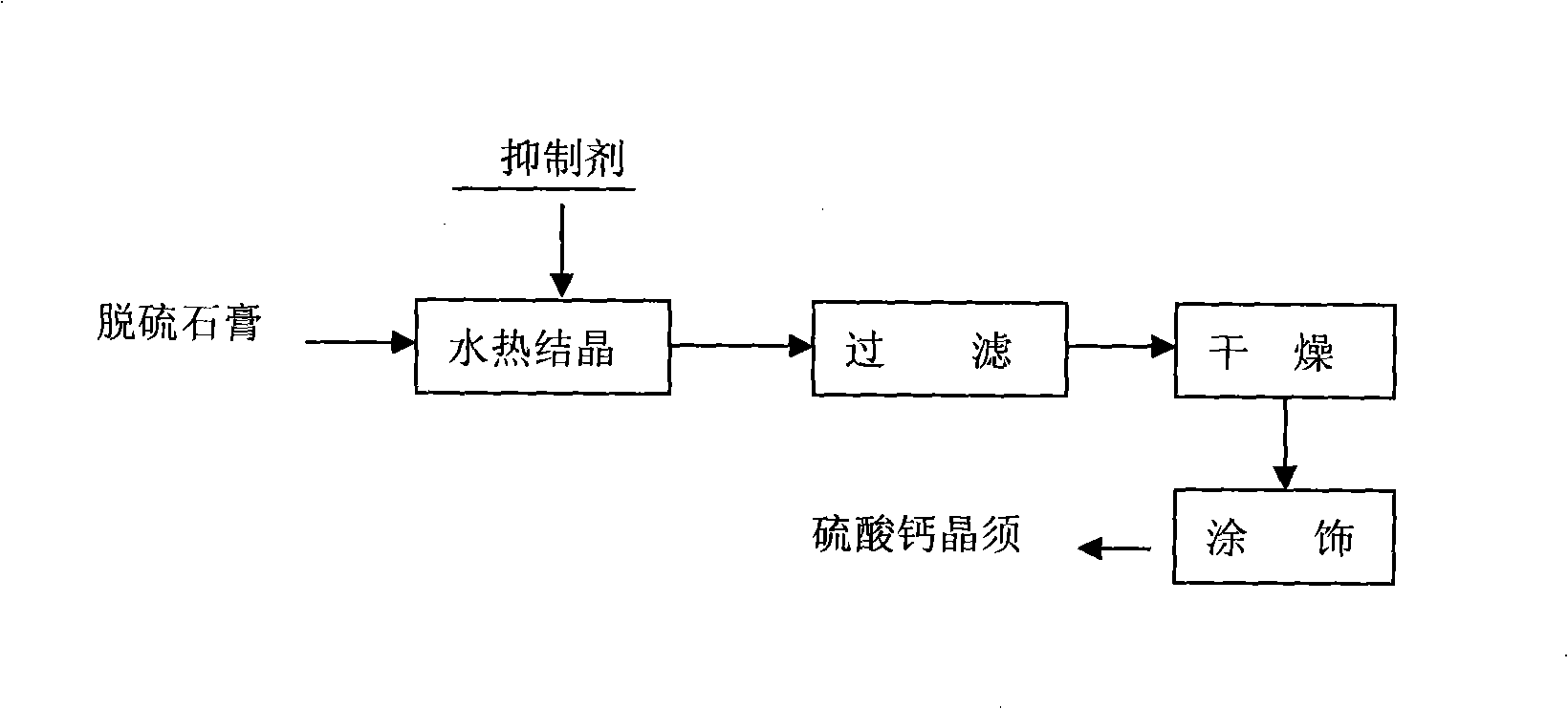

[0021] The process steps are as follows:

[0022] (1) Mixing

[0023] Mix desulfurized gypsum with water at a solid-to-liquid ratio of 1:5, and use inhibitor nitric acid to control the pH to 2;

[0024] (2) high temperature crystallization

[0025] The prepared desulfurized gypsum suspension was kept at a temperature of 110°C, a pressure of 0.2 MPa and a stirring speed of 40 rpm, kept for 40 min, vacuum filtered, and washed with water;

[0026] (3) dry

[0027] The washed calcium sulfate whiskers were kept at a temperature of 80° C. for 30 minutes to obtain calcium sulfate whiskers.

[0028] (4) Modification

[0029] The calcium sulfate whiskers are surface-modified and dispersed with stearic acid, and the amount of the modifier is 0.5% of the quality of the calcium sulfate whiskers to finally obtain calcium sulfate whiskers. After modification, the calcium sulfate whiskers can be mixed with Resin, rubber, plastic and other organic polymer compounds have good descriptive ...

Embodiment 2

[0032] The process steps are as follows:

[0033] (1) Mixing

[0034] Mix desulfurized gypsum with water at a solid-to-liquid ratio of 1:8, and use inhibitor magnesium chloride to control the pH to 3;

[0035] (2) high temperature crystallization

[0036] The prepared desulfurized gypsum suspension was kept at a temperature of 130°C, a pressure of 0.4 MPa, and a stirring speed of 130 revolutions / min, kept for 90 minutes, vacuum filtered, and washed with water;

[0037] (3) dry

[0038] The washed calcium sulfate whiskers were kept at a temperature of 120° C. for 80 minutes to obtain calcium sulfate whiskers.

[0039] (4) Modification

[0040] The calcium sulfate whiskers are surface-modified and dispersed with titanate, and the amount of the modifier is 0.9% of the mass of the calcium sulfate whiskers. Finally, calcium sulfate whiskers are obtained. After modification, the calcium sulfate whiskers can be compared with Resin, rubber, plastic and other organic polymer compo...

Embodiment 3

[0043] The process steps are as follows:

[0044] (1) Mixing

[0045] Mix desulfurized gypsum with water at a solid-to-liquid ratio of 1:11, and use inhibitor hydrochloric acid to control the pH to 4;

[0046] (2) high temperature crystallization

[0047] The prepared desulfurized gypsum suspension was kept at a temperature of 160 ° C, a pressure of 0.7 MPa and a stirring speed of 220 rpm, kept for 140 min, centrifuged, and washed with water;

[0048] (3) dry

[0049] The washed calcium sulfate whiskers were kept at a temperature of 150° C. for 130 minutes to obtain calcium sulfate whiskers.

[0050] (4) Modification

[0051] The calcium sulfate whiskers are surface-modified and dispersed with polyvinyl alcohol, and the amount of modifying agent is 1.3% of the quality of the calcium sulfate whiskers to finally obtain calcium sulfate whiskers. After modification, the calcium sulfate whiskers can be compared with Resin, rubber, plastic and other organic polymer compounds ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com