Preparation method of graphene-coated glass fiber composite material

A graphene-coated and glass fiber technology is applied in the field of preparation of graphene-coated glass fiber composite materials, which can solve problems such as limiting the expansion of application fields, and achieve the effects of obvious decrease in resistivity, easy operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

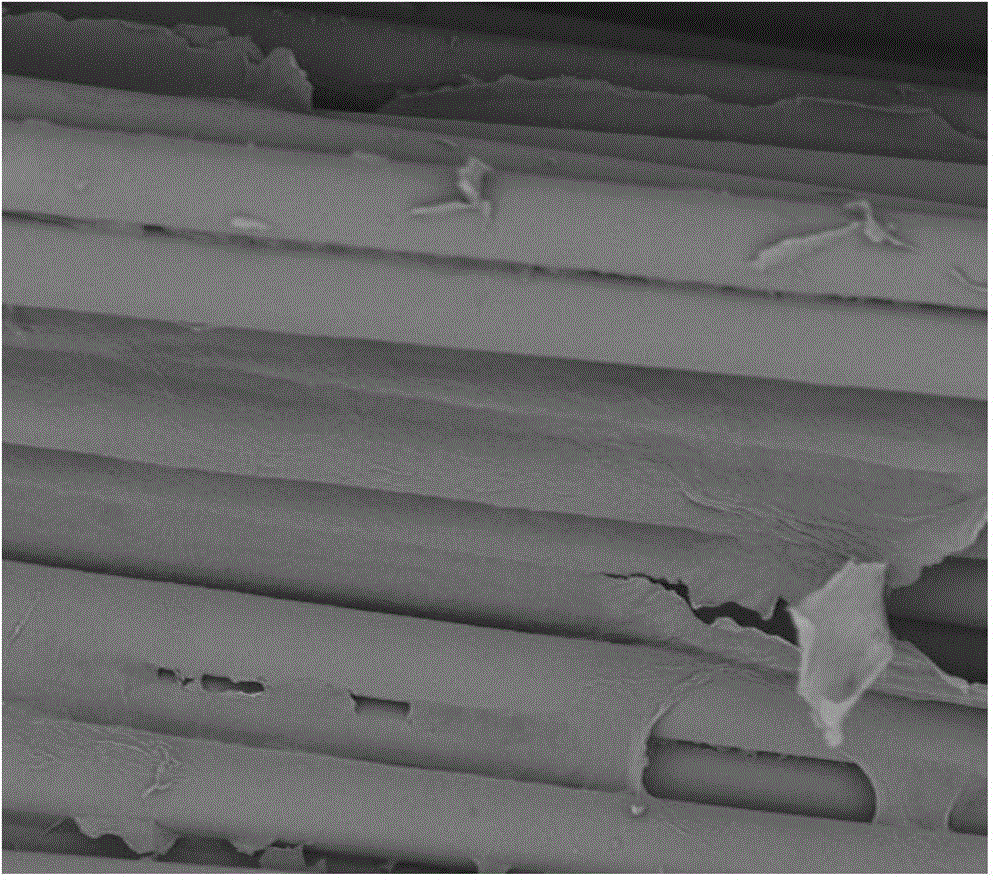

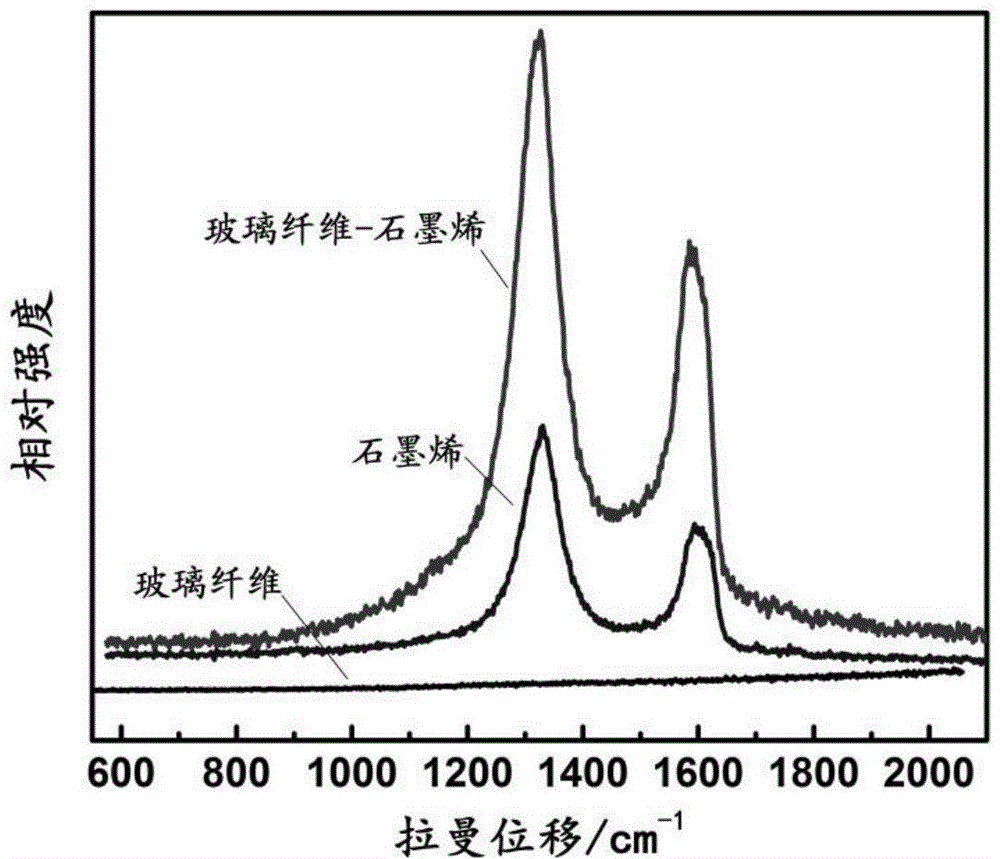

[0027] (1) Put the glass fibers in a muffle furnace at 400°C for thermal cleaning treatment for 50 minutes, then wash them with acetone, 6mol / L hydrochloric acid solution, and deionized water in sequence, and then dry them in an oven at 60°C for later use;

[0028] (2) Soak the pretreated glass fiber in 50 ml of bovine serum albumin solution with a mass fraction of 1.0% for 60 minutes, and pull it every 5 minutes during this period;

[0029] (3) At room temperature, prepare 50 ml of graphite oxide ultrapure water dispersion with a mass fraction of 0.1%, immerse the bovine serum albumin functionalized glass fiber in the graphite oxide dispersion for 30 min, take it out, and rinse with deionized water; Then place it in a 55°C oven and dry it for later use;

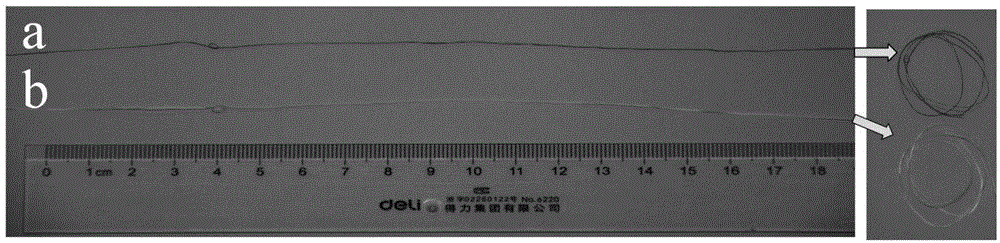

[0030] (4) Put 10ml of the solution prepared by hydroiodic acid and acetic acid in a volume ratio of 1:2 in a sealed container, and at the same time fix the obtained graphite oxide-coated glass fiber on the upper layer of th...

Embodiment 2

[0033] (1) Put the glass fibers in a muffle furnace at 450°C for thermal cleaning treatment for 50 minutes, then wash them with acetone, 6mol / L hydrochloric acid solution, and deionized water in sequence, and then dry them in an oven at 60°C for later use;

[0034] (2) Soak the pretreated glass fiber in 50 ml of bovine serum albumin solution with a mass fraction of 1.5% for 60 minutes, and pull it every 5 minutes during this period;

[0035] (3) At room temperature, prepare 50 ml of graphite oxide ultrapure water dispersion with a mass fraction of 0.1%, immerse the bovine serum albumin functionalized glass fiber in the graphite oxide dispersion for 30 min, take it out, and rinse with deionized water; Then place it in a 50°C oven to dry for later use;

[0036] (4) Put 10ml of hydroiodic acid and acetic acid solution in a volume ratio of 1:3 in a sealed container, and fix the obtained graphite oxide-coated glass fiber on the upper layer of the sealed container, and reduce and ox...

Embodiment 3

[0039] (1) Put the glass fiber in a muffle furnace at 350°C for thermal cleaning treatment for 50 minutes, then wash it with acetone, 6mol / L hydrochloric acid solution, and deionized water in sequence, and then dry it in an oven at 60°C for later use;

[0040] (2) Soak the pretreated glass fibers in 50 ml of bovine serum albumin solution with a mass fraction of 1.25% for 60 minutes, during which, pull once every 5 minutes;

[0041] (3) At room temperature, prepare 50 ml of graphite oxide ultrapure water dispersion with a mass fraction of 0.2%, immerse the bovine serum albumin-functionalized glass fiber in the graphite oxide dispersion for 30 min, take it out, and rinse with deionized water; Then place it in a 50°C oven to dry for later use;

[0042] (4) Put 10ml of hydroiodic acid and acetic acid in a volume ratio of 1:2.5 into a sealed container, fix the obtained graphite oxide-coated glass fiber on the upper layer of the sealed container, and reduce and oxidize it at 40°C G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com