Preparation method of flexible pressure sensor having high sensitivity

A pressure sensor, a flexible technology, applied in the direction of fluid pressure measurement by changing the ohmic resistance, can solve the problems of long relaxation time, failure to return to the original state, and restriction of composite materials, so as to simplify the structure and preparation steps, facilitate operation, eliminate The effect of creep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Preparation of the flexible pressure sensor:

[0040] (1) Disperse multi-walled carbon nanotubes (CNTs) with a diameter of 110–190 nm and a length of 5–9 μm in chloroform, and ultrasonicate for 6 hours to obtain a CNT suspension with good dispersibility.

[0041] (2) Mix the CNT suspension and the PDMS base solution completely in a vortex mixer, then spin evaporate at 90°C for 6h to remove the solvent chloroform, and obtain a mixture of PDMS and CNT.

[0042] (3) Hexane and curing agent were mixed at a ratio of 1:10 and added to the above PDMS-CNT mixture. The ratio was 500 mg of PDMS and 1 mL of hexane. Stir for 5 minutes to make it completely mixed, and degas under vacuum to remove air bubbles.

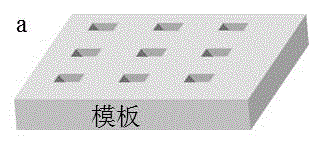

[0043] (4) Take 100 μL of the above mixed liquid and hang-coat it on the micro-template at 600 rpm with a thickness of about 500 μm, and cure at 90°C for 3 hours. The template is obtained by photoetching a silicon wafer, and its surface has periodically arranged inverted tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com