Carbon nanotube-water-soluble polymer composite flexible electric-heating film as well as preparation method and use thereof

A technology of water-soluble polymers and carbon nanotubes, applied in the direction of heating element materials, etc., can solve the problems of low human affinity, high density, overheating, etc., and achieve high human affinity, low working voltage, and low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

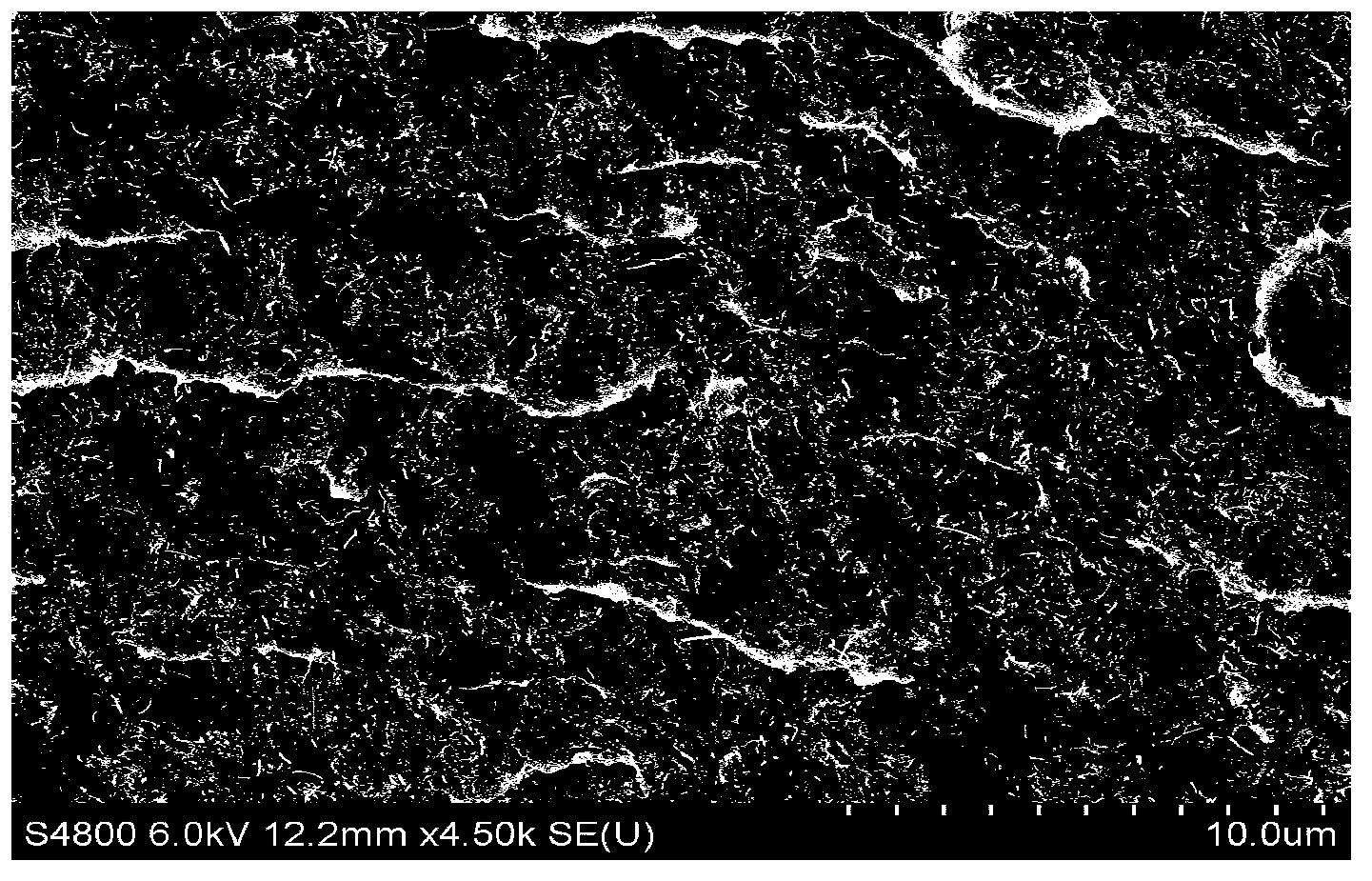

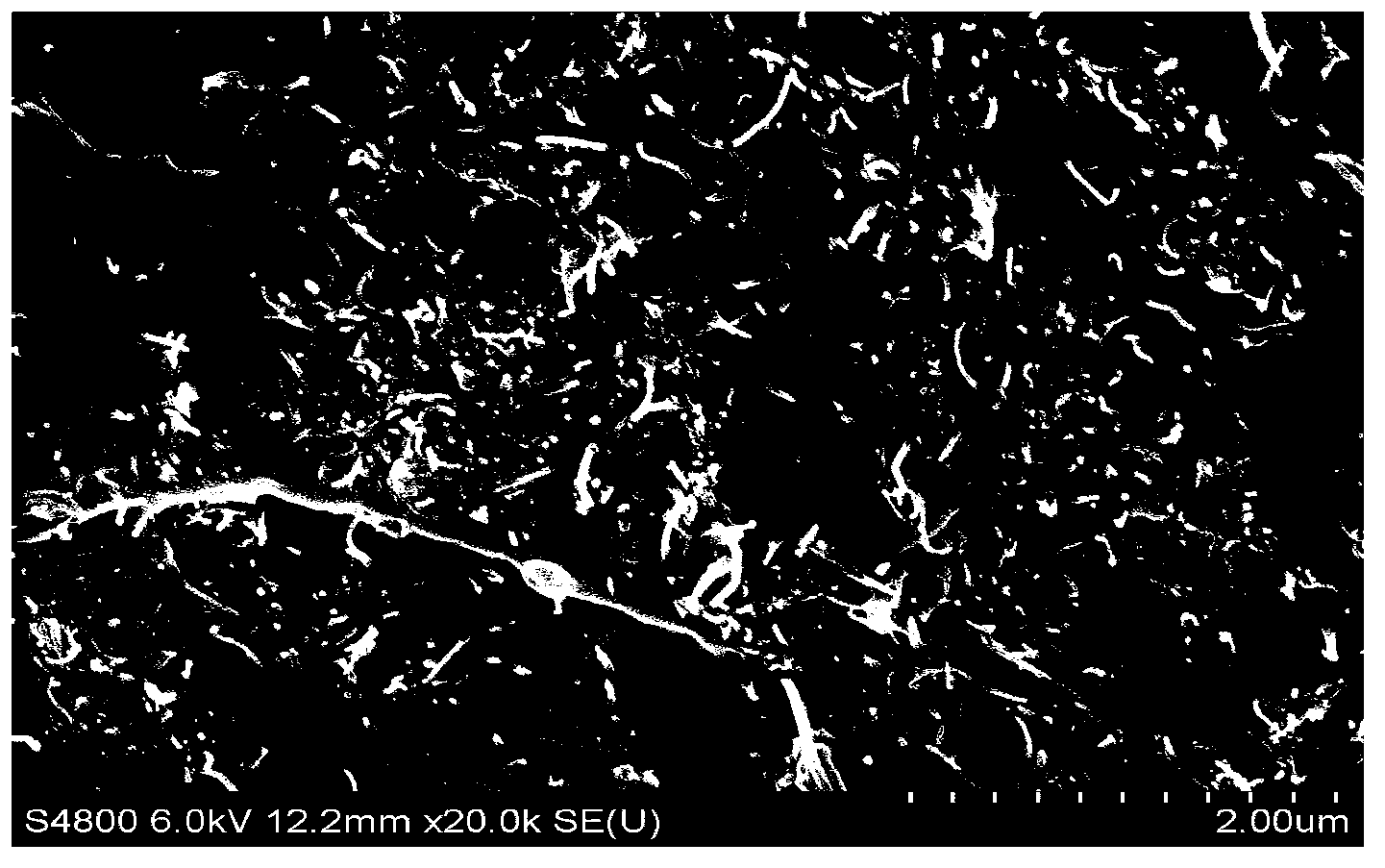

[0045] A carbon nanotube-waterborne polyurethane composite flexible electrothermal film with a carbon nanotube content of 16.7wt% was prepared and its electrothermal effect was studied: the concentration of the carbon nanotube dispersion modified by hydrolyzed maleic anhydride styrene copolymer (HSMA) was 3.3 6.42g of wt% solution, 4.0g of water-based polyurethane (WPU) emulsion with a solid content of 26.5%, stirred for 2.5h with a magnetic stirrer, after mixing evenly, remove the air bubbles under vacuum at room temperature for 20min, and finally placed In a polytetrafluoroethylene mold of ×60mm, the water solvent is removed, and the size is 60×60×0.3mm 3 Film, cutting and coating electrodes with silver glue, the electrode spacing is 30mm, the final size of the obtained film sample is 30×50×0.3mm 3 . Apply a voltage between the electrodes, use a thermocouple to measure the point temperature on the surface, and obtain the curve of temperature rise and time, as shown in the a...

Embodiment 2

[0047] A carbon nanotube-waterborne polyurethane composite flexible electrothermal film with a carbon nanotube content of 13.8wt% was prepared and its electrothermal effect was studied: the concentration of the carbon nanotube dispersion modified by hydrolyzed maleic anhydride styrene copolymer was 3.3wt%. 17.9g of solution, 14.0g of water-based polyurethane emulsion with a solid content of 26.5%, stirred with a magnetic stirrer for 2.5h, after mixing evenly, removed air bubbles under vacuum at room temperature for 20min, and finally placed in a polytetrafluoroethylene with a length and width of 210mm×60mm In the vinyl mold, the water solvent was removed, and the size was 210×60×0.3mm 3 Film, cutting and coating electrodes with silver glue, the electrode spacing is 50mm, the final size of the obtained film sample is 50×100×0.3mm 3 . Apply a voltage between the electrodes, use a thermocouple to measure the point temperature on the surface, and obtain a curve of temperature ris...

Embodiment 3

[0049] A carbon nanotube-waterborne polyurethane composite flexible electrothermal film with a carbon nanotube content of 13.8wt% was prepared and its electrothermal effect was studied: the concentration of the carbon nanotube dispersion modified by hydrolyzed maleic anhydride styrene copolymer was 3.3wt%. 17.9g of solution, 14.0g of water-based polyurethane emulsion with a solid content of 26.5%, stirred with a magnetic stirrer for 2.5h, after mixing evenly, removed air bubbles under vacuum at room temperature for 20min, and finally placed in a polytetrafluoroethylene with a length and width of 210mm×60mm In the vinyl mold, the water solvent was removed, and the size was 210×60×0.3mm 3 Film, cutting and coating electrodes with silver glue, the electrode spacing is 20mm, the final size of the obtained film sample is 20×5×0.3mm 3 , electrified heating research, obtained the temperature rise effect under different voltages as follows Figure 4 Shown, where the room temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com